Application of modeling reverse engineering technology based on laser scanning in construction supervision

A technology of reverse engineering and laser scanning, which is applied in the field of laser scanning, can solve the problems of consuming a lot of manpower and time, the accuracy of real data cannot be guaranteed, and the inability to analyze macro data, so as to achieve accurate supervision analysis, improve management quality and project management efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

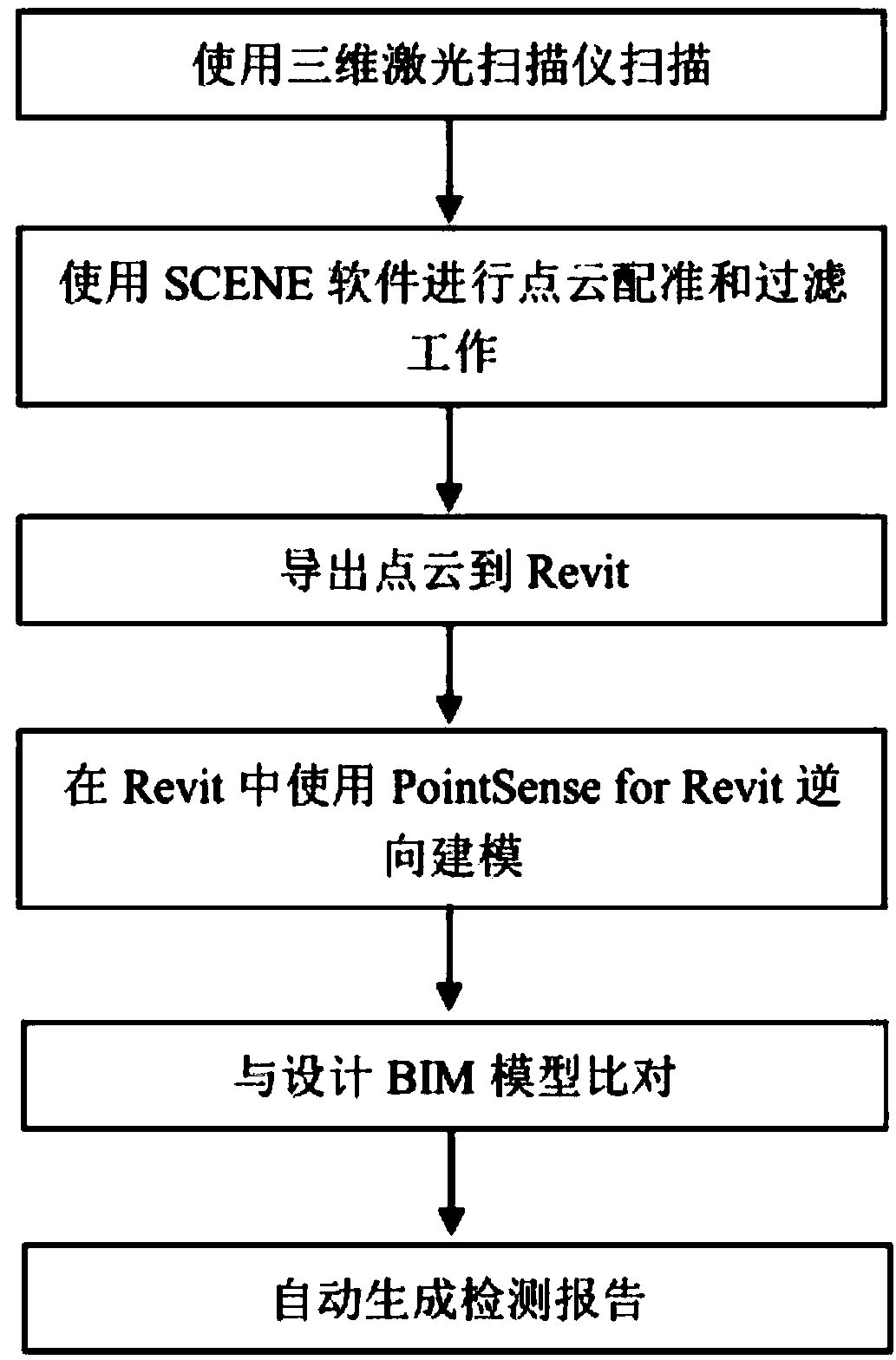

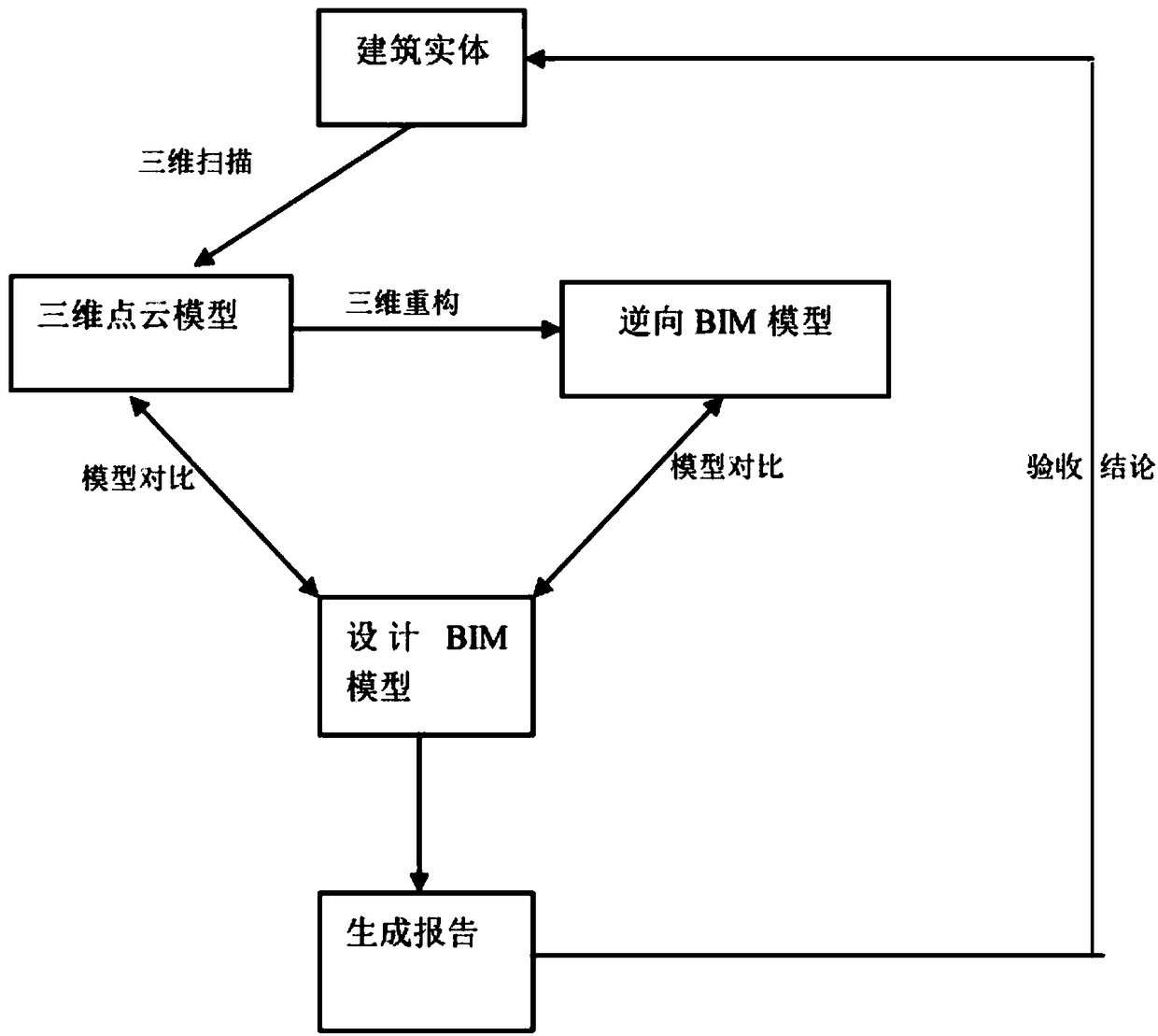

[0025] combined with Figure 1-2 , an application method of reverse engineering technology based on laser scanning modeling, comprising (1) laying out stations, including arranging the number and positions of scanner targets according to the specific construction earthwork area;

[0026] (2) Setting scanning parameters, including setting scanning resolution, and ensuring that the scanning target arranged in step (1) can be correctly identified by the scanner;

[0027] (3) Station splicing, including multi-station scanning according to the construction area and splicing the scanned data of each station;

[0028] (4) point cloud data processing, including uploading the data obtained in step (3) to the point cloud, and performing point cloud data splicing, earthwork boundary determination, noise removal, surface construction, and elevation datum level determination;

[0029] (5) earthwork calculation, including reverse modeling, loading measured model and design model according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com