Digital pre-assembling method of building steel structure based on three-dimensional scanning and reverse modeling

A reverse modeling and three-dimensional scanning technology, applied in 3D modeling, electrical digital data processing, CAD numerical modeling, etc., can solve problems such as potential safety hazards, large assembly sites, time-consuming and labor-intensive problems, and reduce computer burden , reduce the amount of data, improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

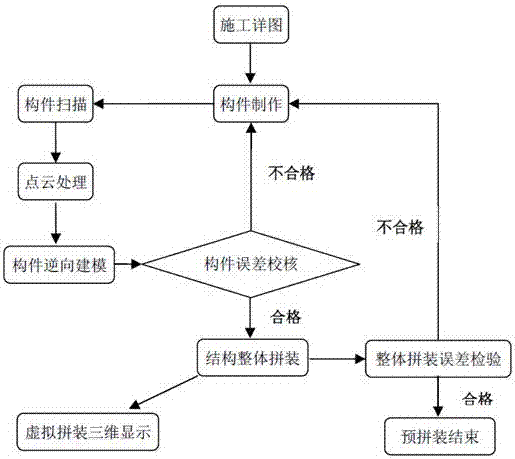

[0028] like figure 1 Shown: a digital pre-assembly method for building steel structures based on 3D scanning and reverse modeling, characterized in that it includes the following steps:

[0029] Step 1: Component fabrication;

[0030] The steel structure detailing model is established through the steel structure detail drawing software, and the processing plant processes and manufactures the components according to the construction drawings after the steel structure deepening;

[0031] Step 2: component scanning;

[0032] Use the 3D laser scanning equipment to scan the processed components, or scan the partially assembled components to form a holographic point cloud data model of the components;

[0033] Step 3: point cloud processing;

[0034] Use the point cloud processing software to stitch, denoise, and streamline the point cloud data model, and clear all other data except the point cloud data model to achieve the preparation conditions for the next step of processing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com