Voltage transformer with elbow plug

A technology for voltage transformers and plugs is applied in the field of transformers, which can solve the problems of epoxy resin damage of transformers, inability to be popularized and applied, and scrapped products, etc., and achieve the advantages of miniaturization design, guarantee of electrical performance, and convenient installation and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

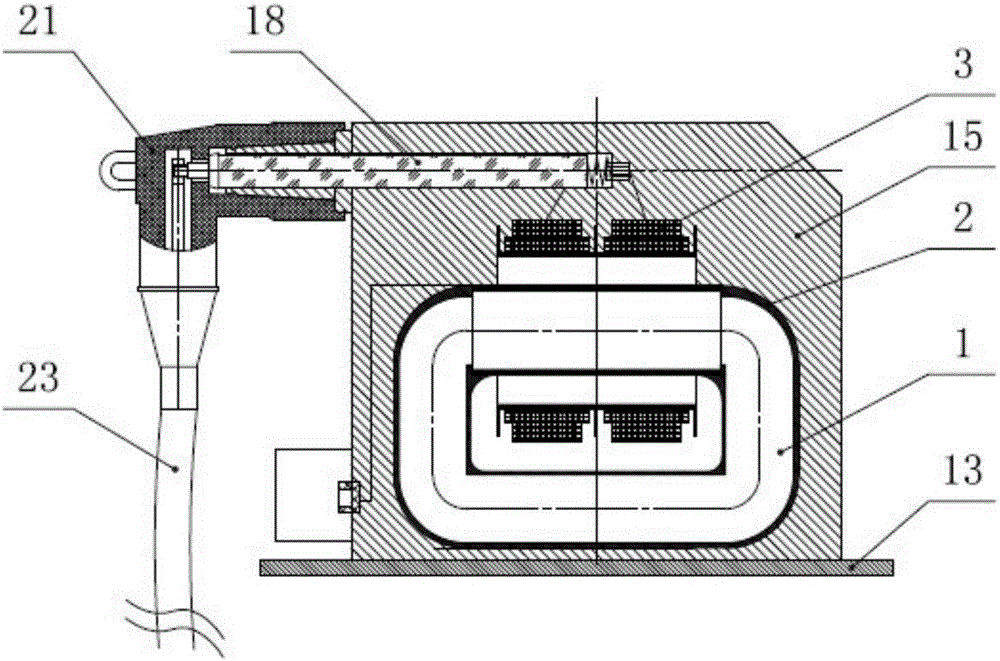

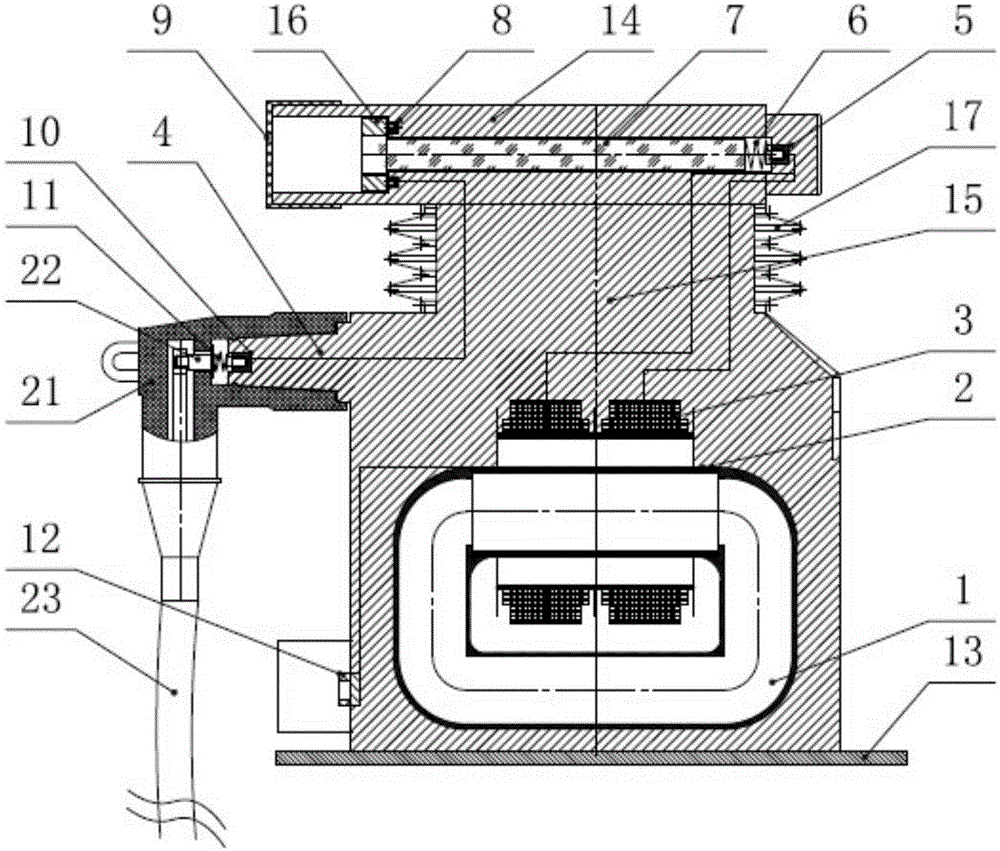

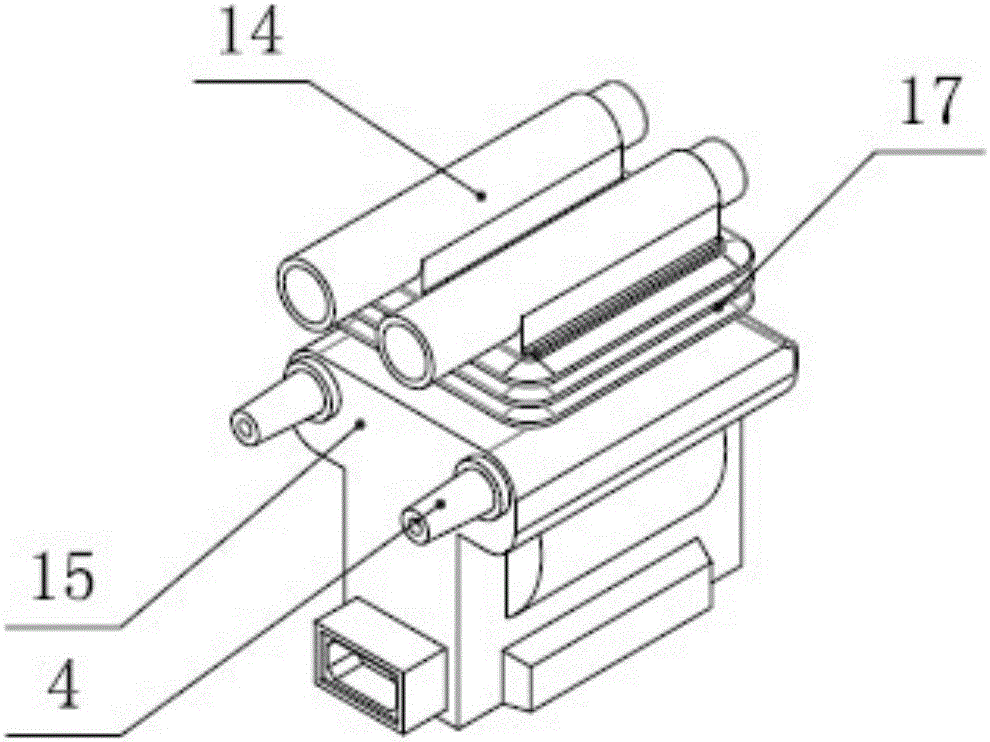

[0019] Please refer to figure 2 and image 3 As shown in the figure, a voltage transformer with an elbow plug is a single mutual inductor structure, the A and B ends of the primary winding 3 are connected to the high-voltage line, and the secondary winding 2 directly outputs the voltage through the electromagnetic induction of the annular iron core 1. It is used for measurement and control of the secondary system. Its structure includes epoxy resin casting main body 15, elbow cable plug 21, fuse 7 and epoxy resin casting integrated primary winding 3, secondary winding 2, iron core 1, cable socket 4, epoxy resin casting A bottom plate 13 is installed under the main body 15, and a secondary terminal 12 is provided at the lower part of the epoxy resin cast main body 15. The secondary terminal 12 is connected to the secondary winding 2, and the bottom end of the elbow-shaped cable plug 21 is connected to a high-voltage cable 23. The high-voltage cable 23 is introduced into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com