Method for molding simulated thread high-pressure injection die

An injection mold and molding method technology, applied in the field of molding molds for automotive interior parts, can solve the problems of excessively long process flow, poor dimensional stability, and high single-piece cost, and achieve the reduction of supporting personnel, stable external dimensions, and shortened process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

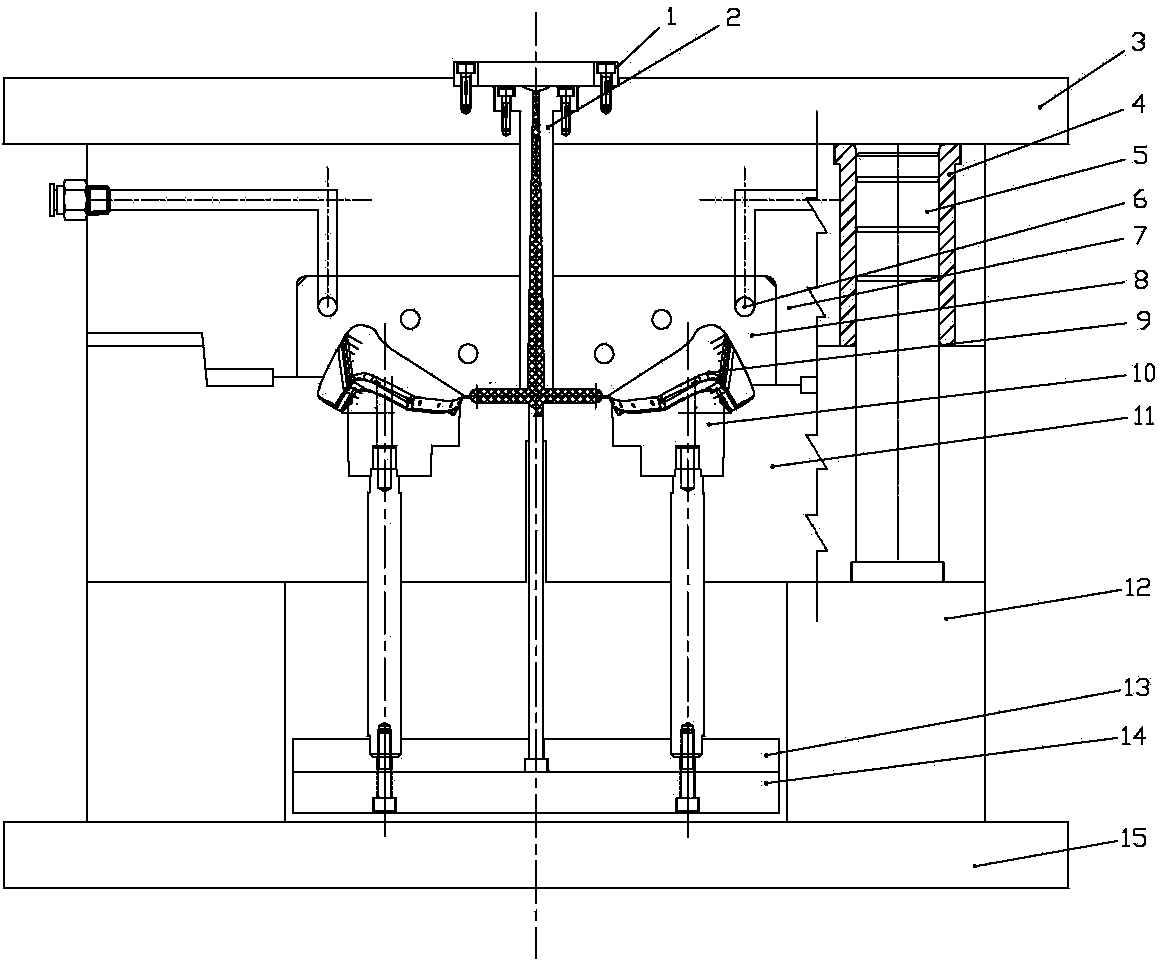

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] The main inventive point of the present invention is the making of the cavity in the mould, which can be made using the following manufacturing techniques:

[0020] Method 1: The process is that the product designer uses 3D design software to model the required 3D model. The digital model should include the pattern of the sewing thread groove, the pattern of the sewing thread and the detailed features of the sewing thread, and then the mold designer based on The digital model separates the male and female molds and designs the structure of the mold. After the completion, the CNC machining center is used to carve out the required sewing lines and various lines, and the cavity is processed with bite lines. After the cavity is made, it is loaded into the master mold and locked together with bolts.

[0021] Method 2: 1. Use a CNC milling machine to process the product s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com