Calibration method of surface densitometer

A calibration method and surface density technology, applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of manpower, material resources and time costs, complicated operations, product scrapping, etc., to avoid manual sampling errors, improve calibration accuracy, Cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Follow the steps below to calibrate an areal density meter:

[0046] (1) Select the position of the radiation source of the surface density measuring instrument for temperature correction as the standard pole piece measurement point, and record the coordinates of the radiation source at this time;

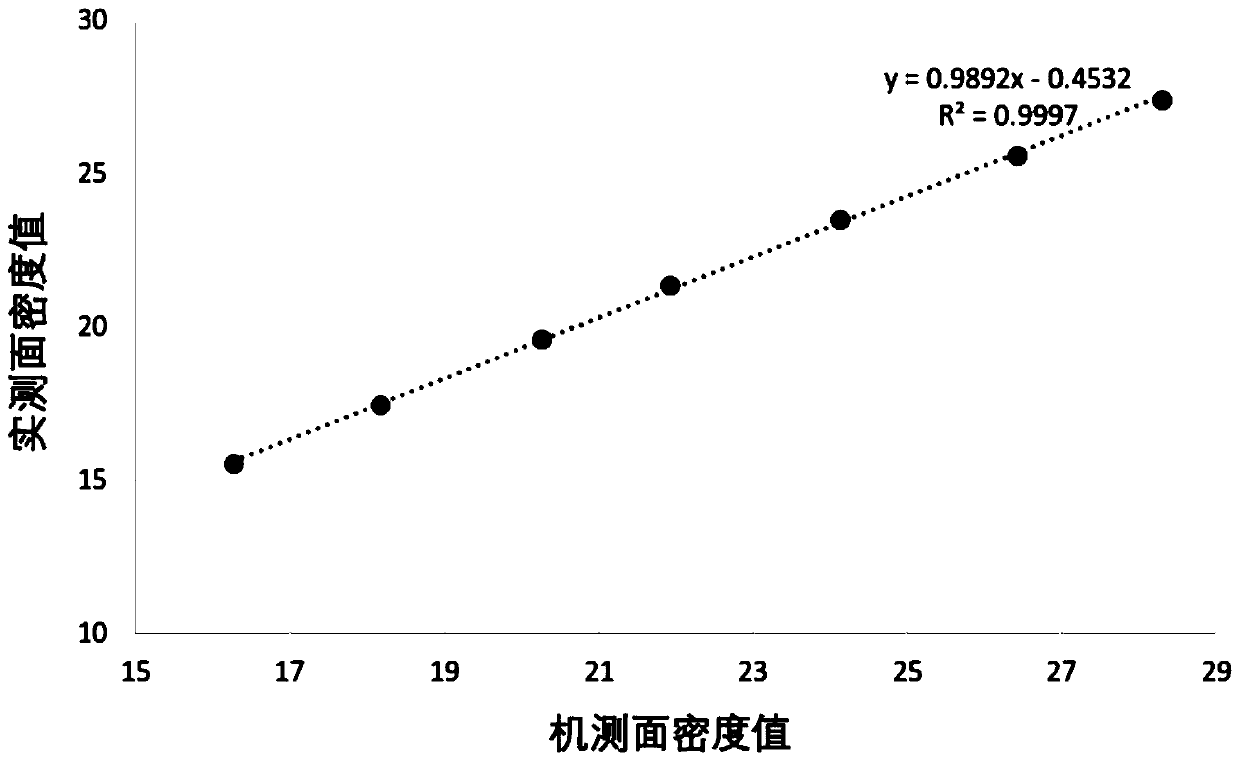

[0047] (2) Make 7 standard pole pieces with a diameter of 30 mm and a gradient surface density value, use a high-precision electronic scale to weigh the weight of each standard pole piece, and calculate the surface area of each standard pole piece combined with the surface area and weight of the standard pole piece Density measured value, the results are shown in Table 2;

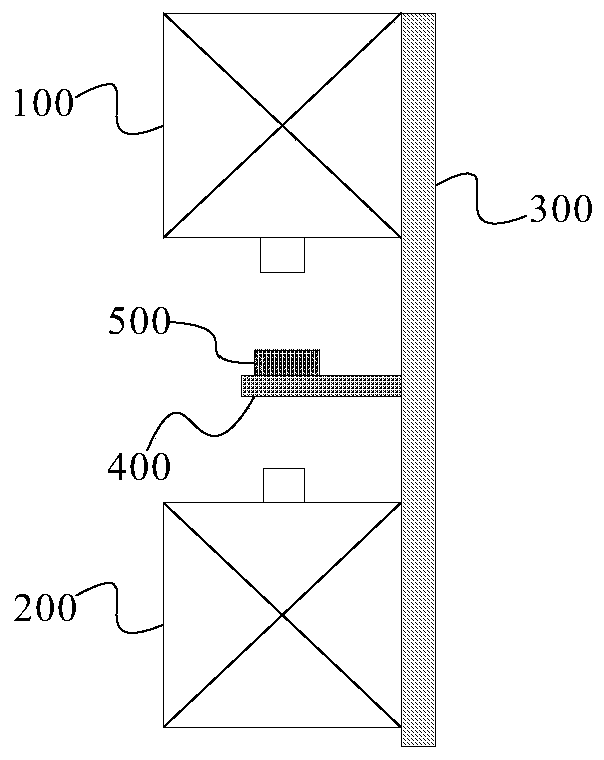

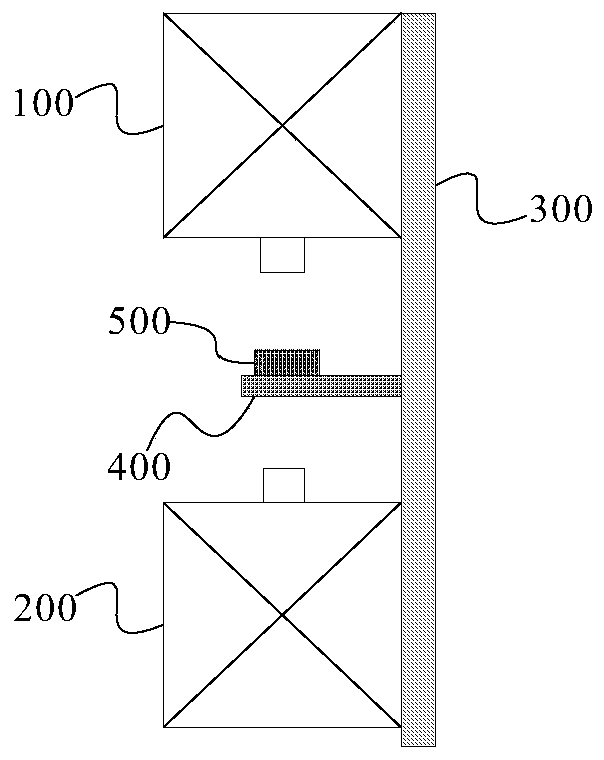

[0048] (3) Install the jig used to fix the standard pole piece on the ray source support rod of the surface density measuring instrument, and it is located at the midpoint of the distance between the ray source and the ray receiving unit in the vertical direction, and place the standard pole piece on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com