Solar battery assembly

A technology for solar cells and solar cells, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of irreparable solar cell components, difficult electrode welding, waste of cost, etc., to increase the use environment and service life, and reduce the process. Difficulty and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

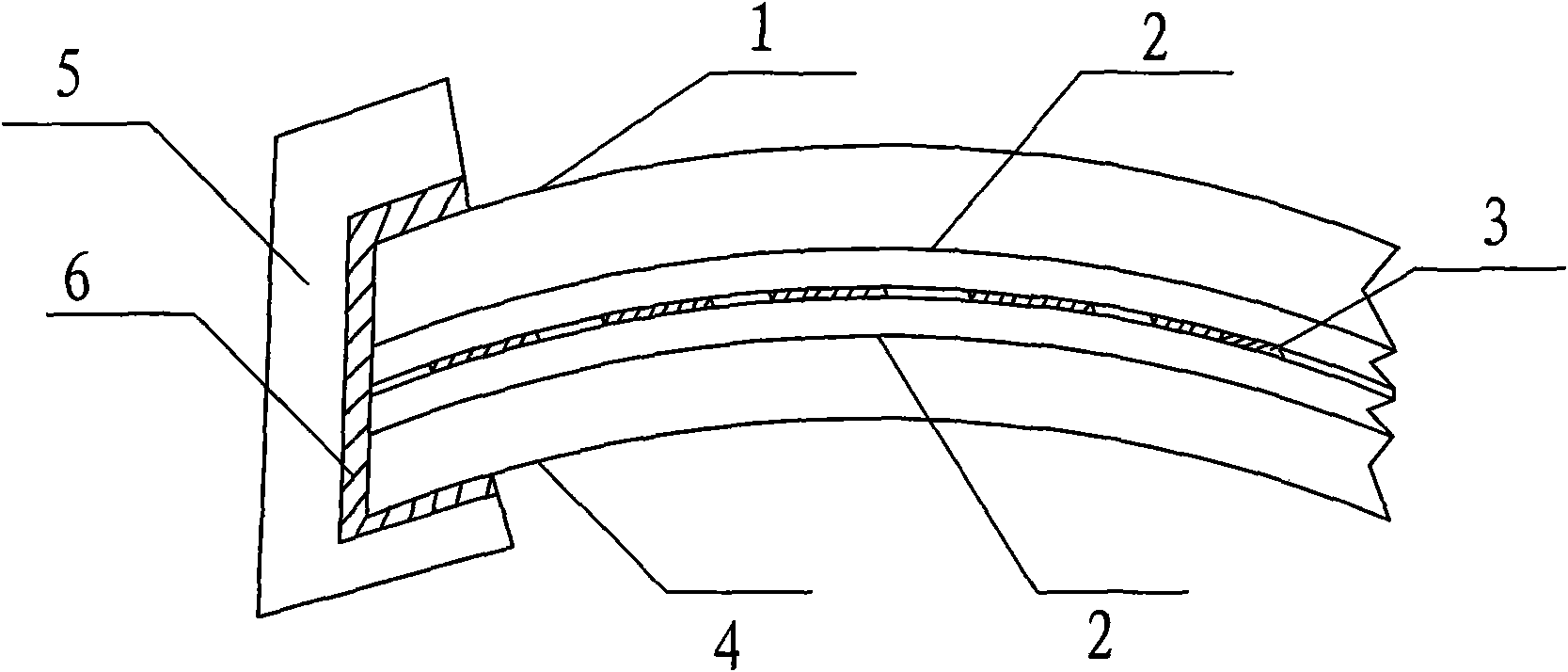

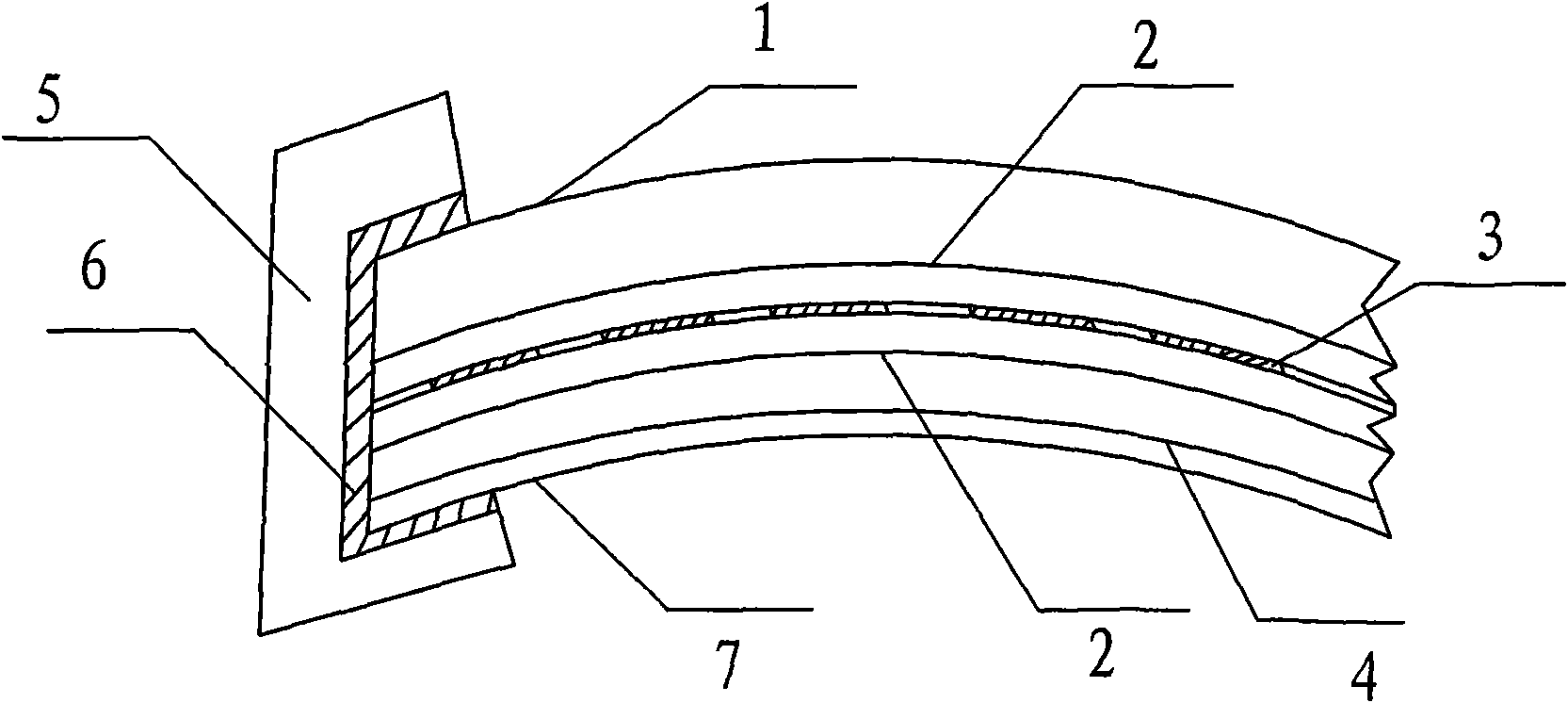

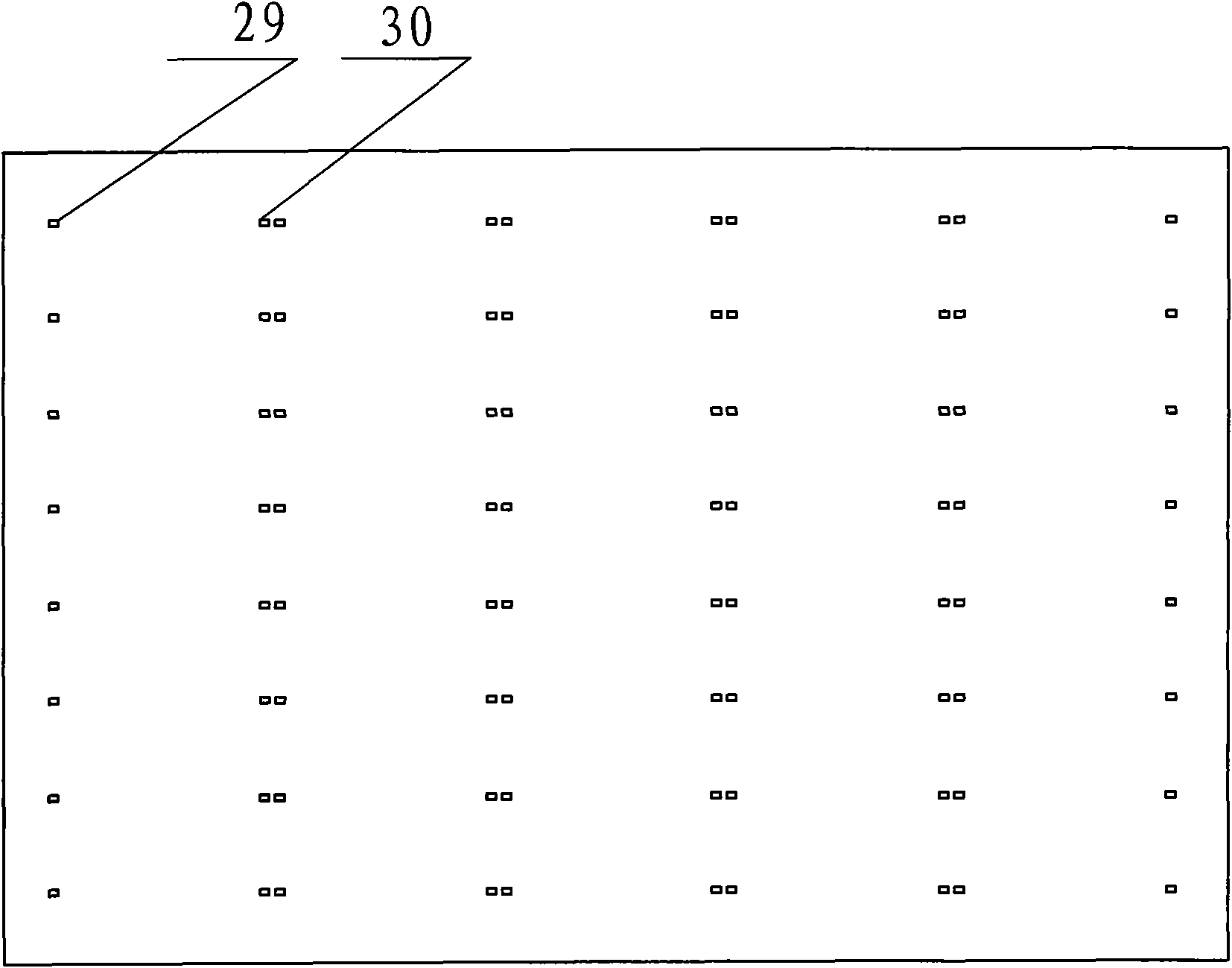

[0015] The invention provides a solar cell assembly which is easier to realize series-parallel connection of solar cell sheets, easy to connect electrodes, not easy to desolder, flexible and adjustable in series-parallel connection, repairable, more stable in performance, and easier to prepare. It includes a light-transmitting top cover, a number of solar cells, adhesives and carriers; several solar cells are located between the light-transmitting top cover and the carrier; adhesives are filled between the light-transmitting top cover and the carrier; some solar cells The cells are connected in series, in parallel or in combination; the solar cells contain positive and negative electrodes for drawing current; among them, the positive and negative electrodes of the solar cells are connected to the carrier as the connection points of the positive and negative electrodes. The series connection, parallel connection or mixed connection between them are realized through the electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com