Refrigerating chamber heat-exchange refrigerator integration all-in-one machine and working method thereof

A cold room and all-in-one technology, which is applied to coolers, household refrigerators, cooling fluid circulation devices, etc., can solve the problems of low cost performance, increased air-conditioning power consumption, and waste of refrigerator heat, etc., to achieve the effect of improving cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

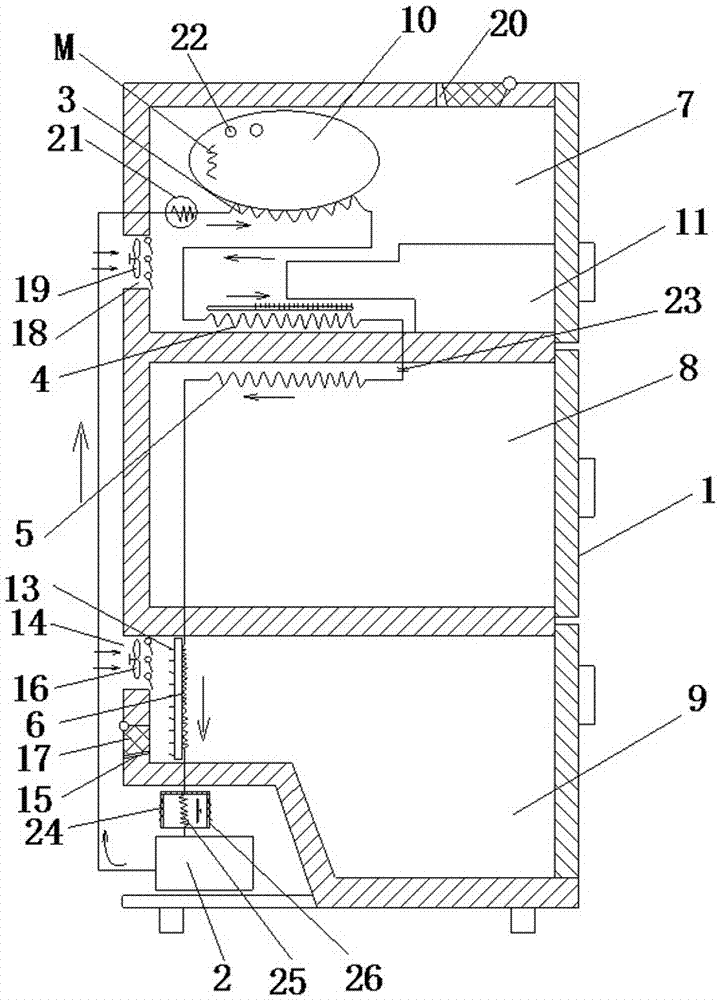

[0034] The difference between Embodiment 3 and Embodiment 1 is that Embodiment 3 is based on Embodiment 1. The return end of the above-mentioned compressor is provided with a heat preservation valve box 24, and the heat preservation valve box is provided with an evaporative suction valve arranged in a circuitous manner. Heat pipe 25, described insulation flap box is provided with insulation flap door 26, and it enables in winter, does not use in summer, plays to increase the return temperature of compressor, increases thermal efficiency.

example 2

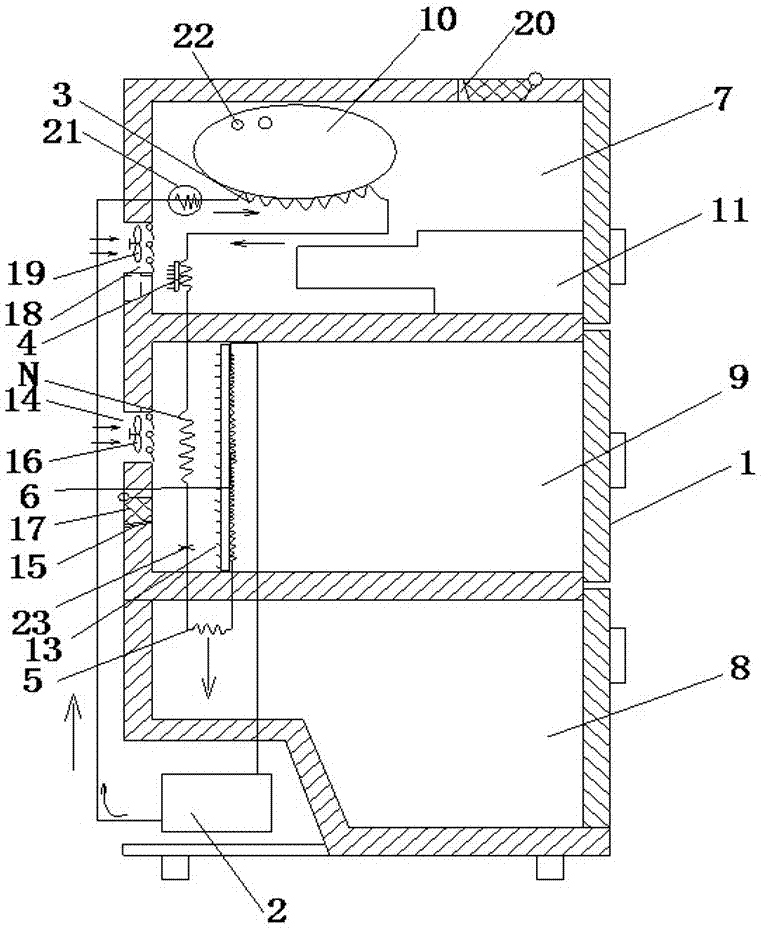

[0035] The difference between Example 2 and Example 1 is that the upper and lower positions of the freezing room and the refrigerating room are adjusted, and a condensing radiator is added in the refrigerating room, which can increase the condensation effect and increase the stability of temperature control .

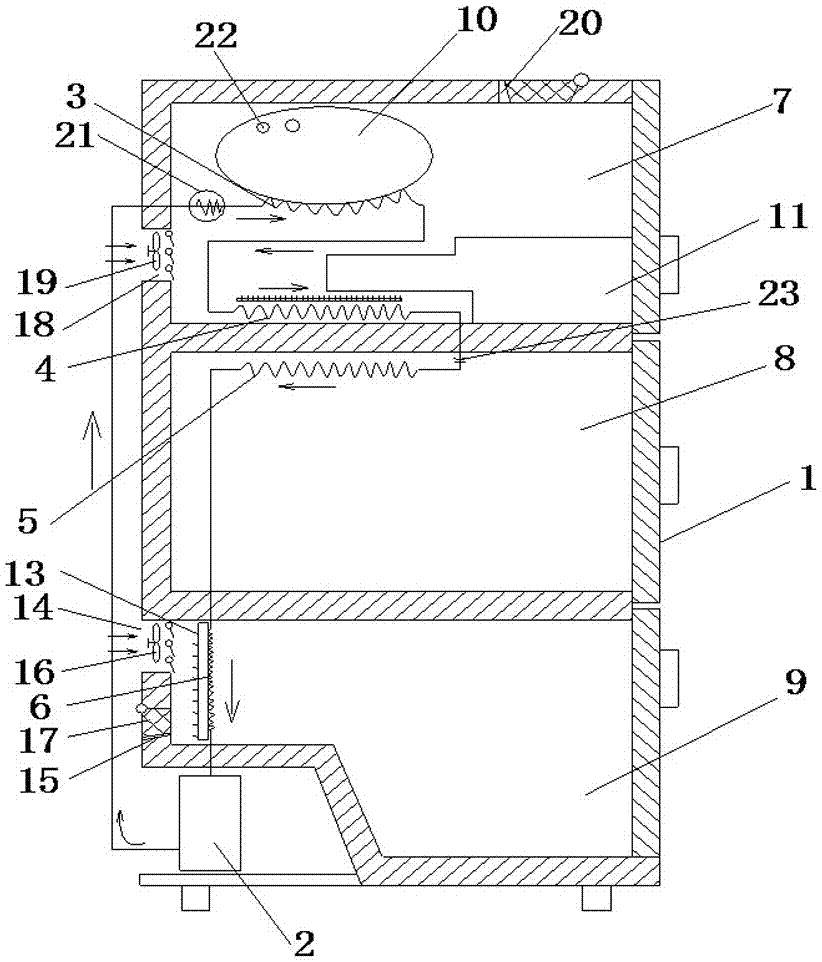

[0036]The working method of the all-in-one machine for heat exchange refrigerator in the refrigerating room of the present invention, wherein the all-in-one machine for heat exchange refrigerator in the refrigerating room includes a refrigerator box 1 and a compressor 2 connected in sequence on the back of the refrigerator box 1, a water tank condenser 3, and an incubator Condenser 4, refrigerating evaporator 5 and refrigerating evaporator 6, described refrigerator casing 1 comprises heat preservation chamber 7, freezing chamber 8 and refrigerating chamber 9 from top to bottom; Described heat preservation chamber 7 is provided with water tank 10 and insulation cavity 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com