Primary-gear-gearing-down compact-type mid-motor

A technology of gear reduction and central motor, which is applied to wheeled transmissions, motor vehicles, electromechanical devices, etc., can solve the problems of large space of multi-stage gear reduction mechanism, insufficient compact structure and volume of motor, inconvenient installation and positioning of motor, etc. Achieve the effect of saving production resources, fewer parts and reducing the volume of the shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

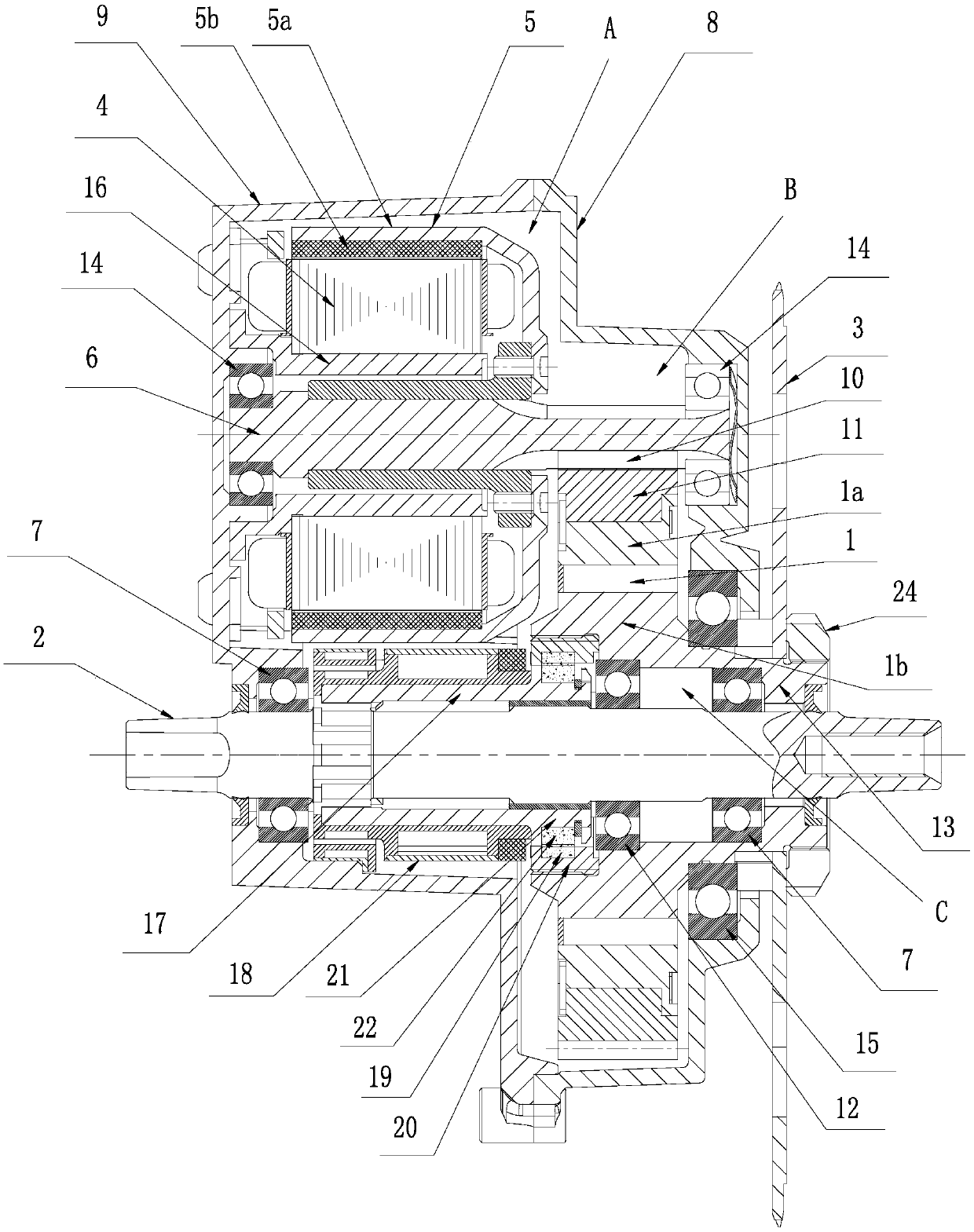

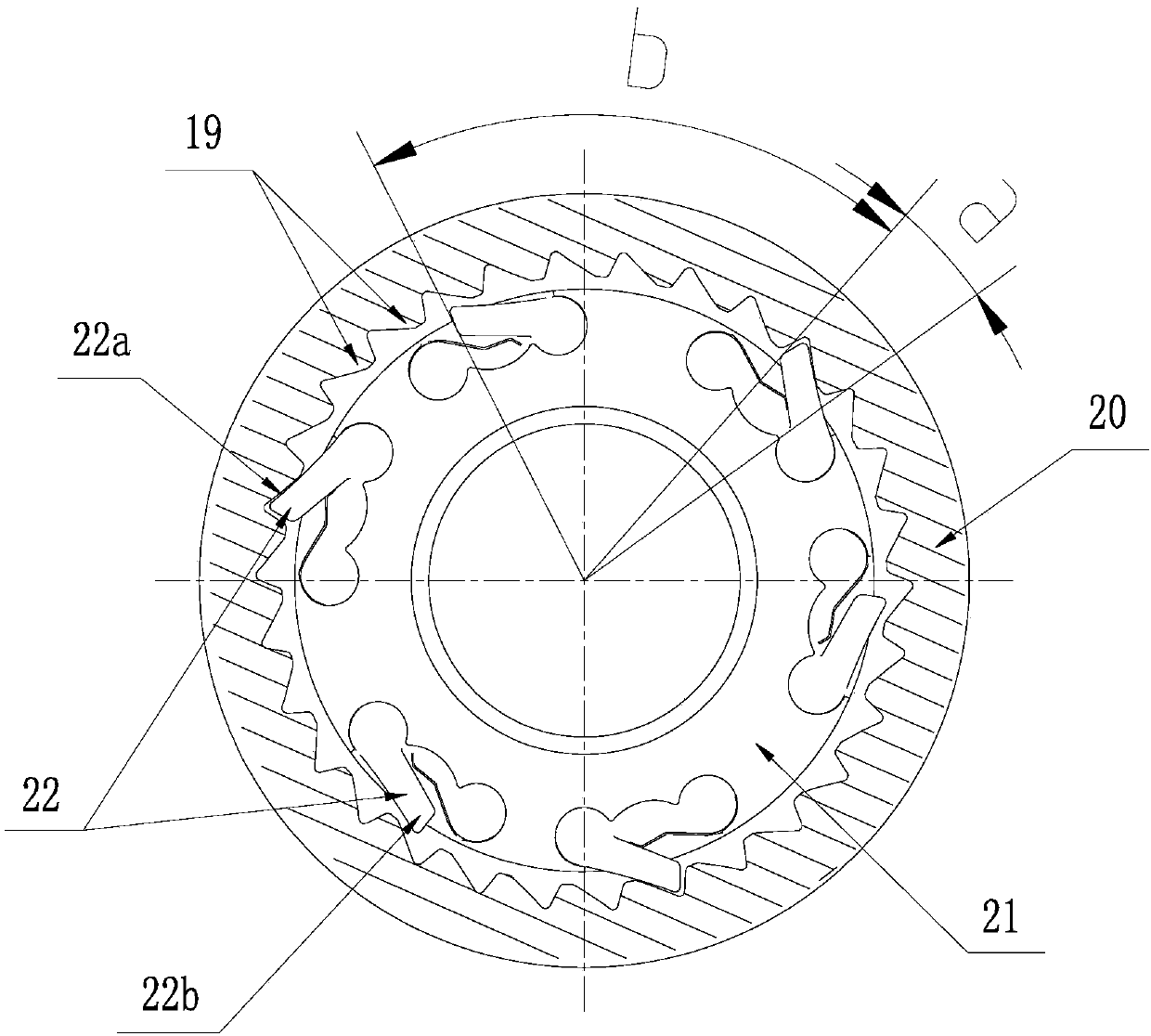

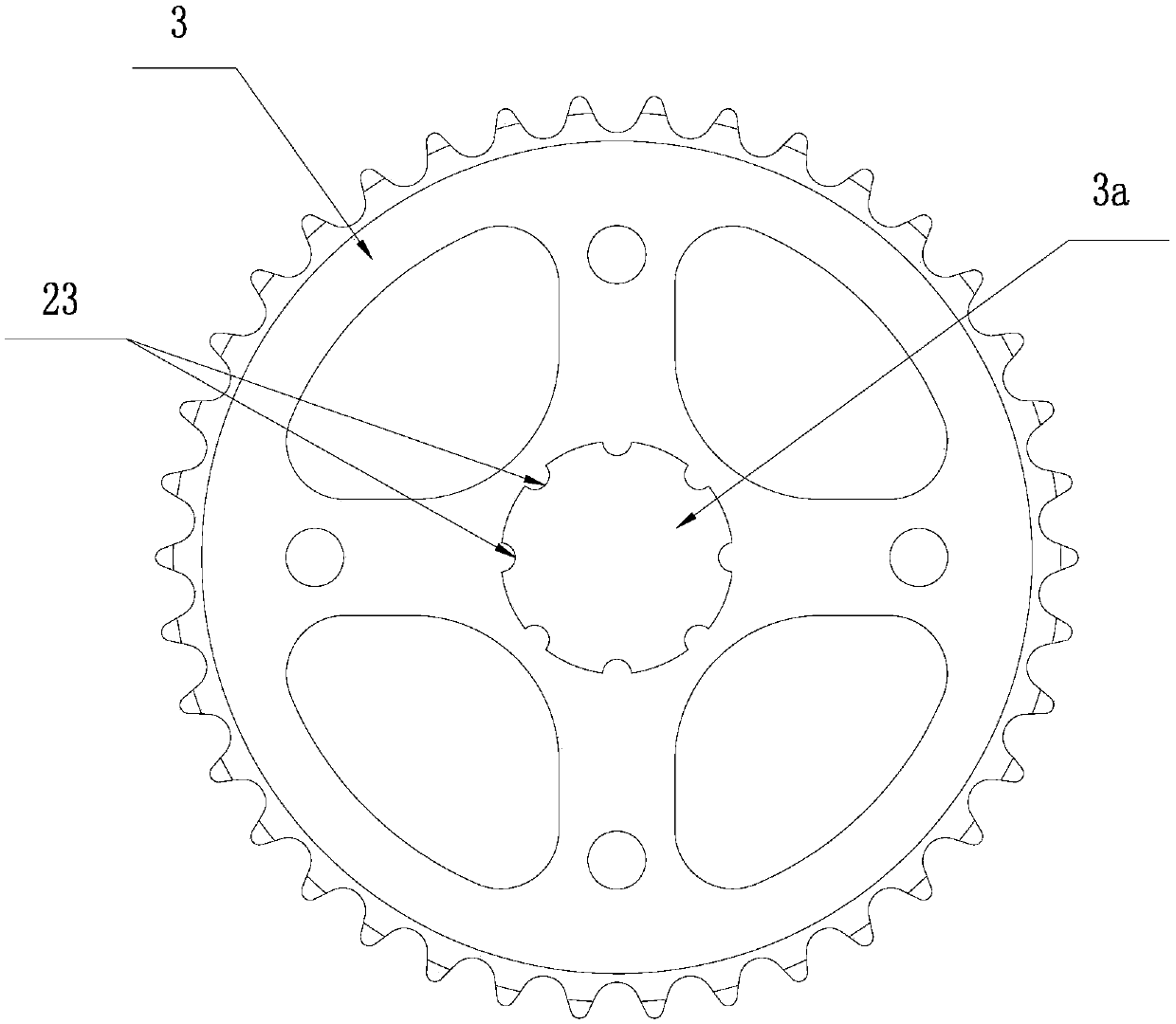

[0031] Embodiment: combine below Figure 1~Figure 3 The specific implementation of the compact mid-mounted motor with one-stage gear reduction transmission provided by the present invention is described as follows:

[0032] Such as figure 1 Shown, it has shell, motor body, clutch 1, gear reduction mechanism, central shaft 2, chainring 3, sensor sleeve 17, torque sensor 18 and one-way ratchet mechanism the same as conventional technology. The motor body includes a stator 4, a rotor 5 and a mandrel 6 fixed to the rotor 5. The central shaft 2 passes through the shaft holes at both ends of the casing and is supported and positioned by the central shaft bearing 7 arranged in the casing. The mandrel 6 is parallel to the central shaft 2. layout. The core improvement of the present invention is:

[0033] The casing of the present invention cancels the design of the middle cover of the motor, and is directly fastened and fixed by the motor front cover 8 and the motor rear cover 9. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com