End face superfinishing machine

A technology of superfinishing machine and end face, which is applied to the parts of grinding machine tools, grinding machines, grinding/polishing equipment, etc., and can solve the problem that stepped eccentric shaft parts cannot be used when they are scrapped, damaged stepped eccentric shaft parts, and grinding wheels contain Impurities and other problems, to achieve the effect of small impurities, convenient operation, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

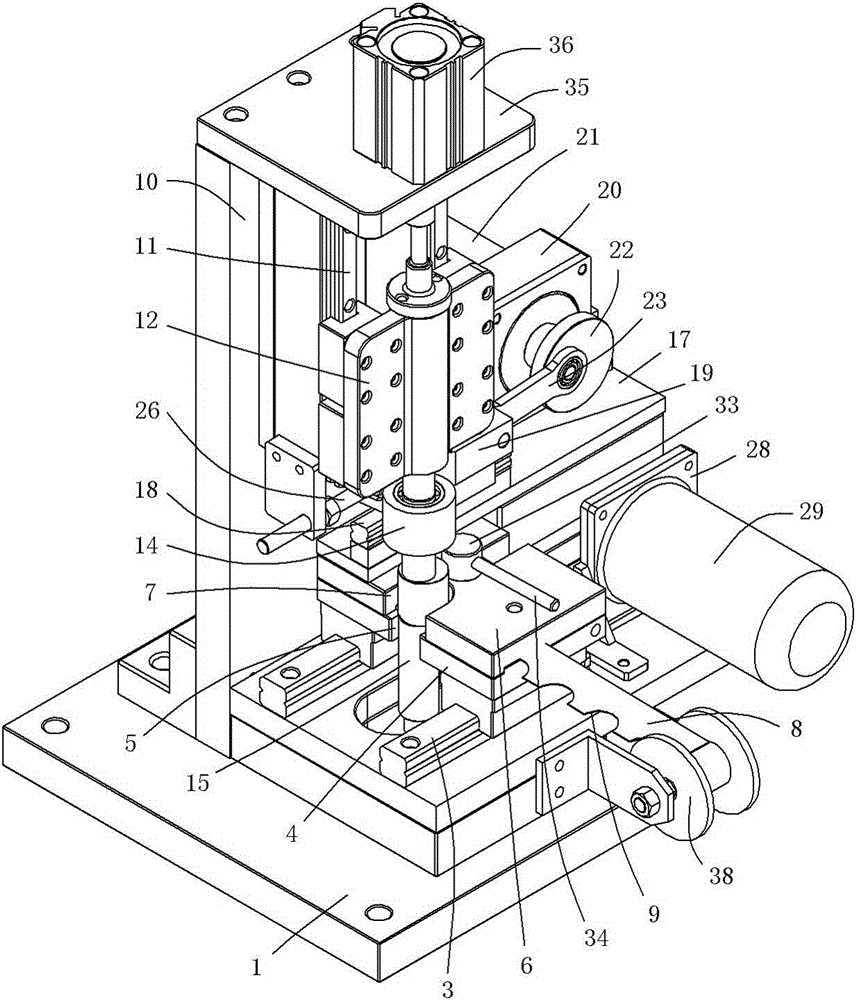

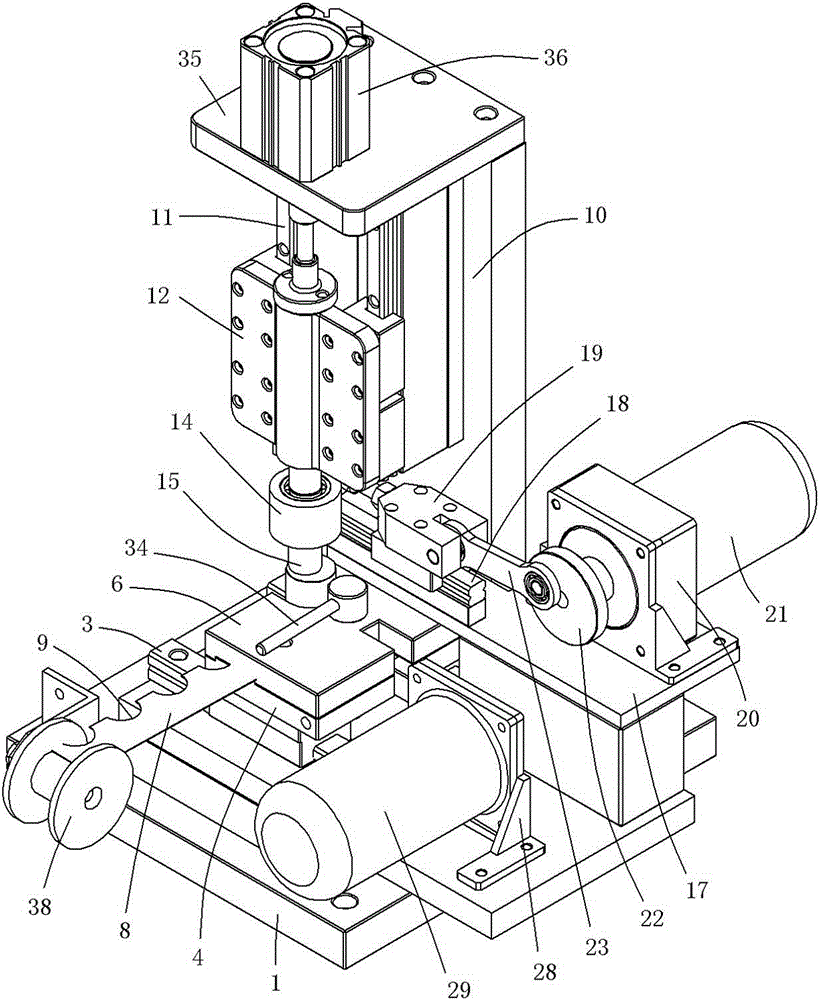

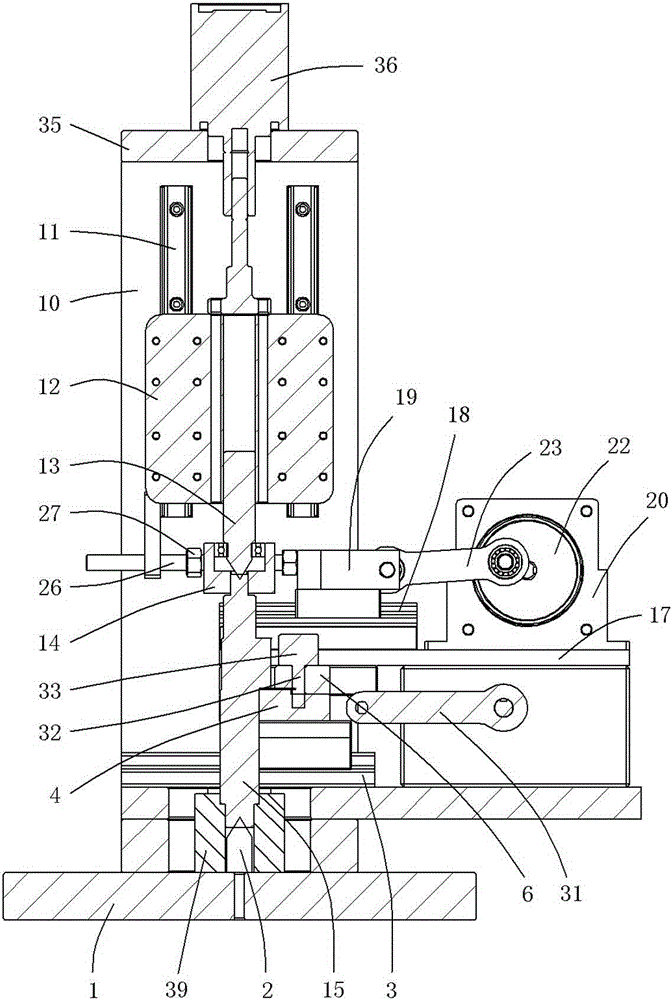

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] refer to Figure 1~Figure 5 , an end face superfinishing machine, comprising a frame, a worktable 1 arranged on the frame, and a lower top 2 supported on the lower end of the workpiece is vertically fixed on the worktable;

[0029] An abrasive belt guide rail 3 is longitudinally arranged on the workbench, and an abrasive belt lower splint 4 is slid on the abrasive belt guide rail. The abrasive belt lower splint is driven by the abrasive belt longitudinal movement driving mechanism so as to move forward and backward along the abrasive belt guide rail. Move, the lower splint of the abrasive belt is provided with a lower U-shaped groove 5 that opens forward and can be located directly above the lower top;

[0030] The top of the lower clamping plate 4 of the abrasive belt is provided with an upper clamping plate 6 of the abrasive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com