A small high -density multi -core optical fiber connector

A multi-core optical fiber, high-density technology, applied in the field of optical fiber communication, can solve the problems of overall product scrap, large loss, low integration, etc., and achieve the effects of convenient disassembly, low maintenance cost, and short length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

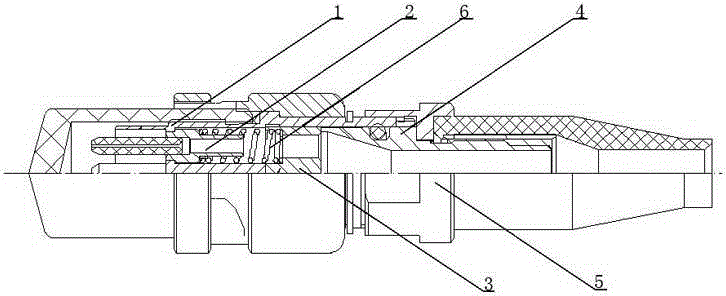

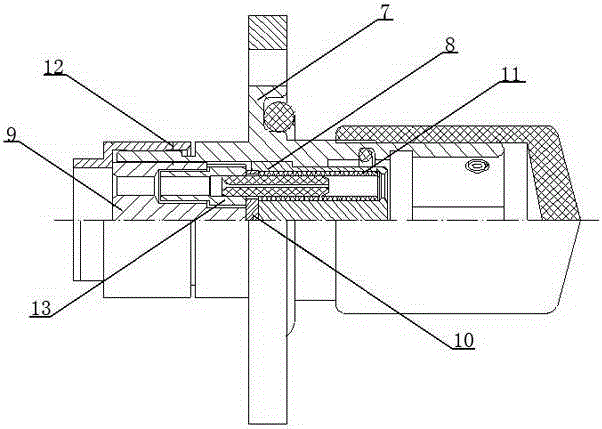

[0013] As shown in the figure: a small high-density multi-core optical fiber connector, including a plug and a socket, the plug includes a spline housing 1, a pin part 2, a pin pressing plate 3, a rear top sleeve 4 and a fastening nut 5, The spline housing 1 has four chambers along the axial direction, each chamber is provided with a pin part 2, the head of the pin part 2 will not come out of the spline housing 1, and the pin The tail of the part 2 is provided with a pin pressing plate 3, and a spring 6 is arranged between the pin part 2 and the pin pressing plate 3, and the pin part 2 is tightened by the spring 6, and the fastening nut 5 is arranged on the spline At the tail of the housing 1, the fastening nut 5 is threadedly connected with the spline housing 1, and after the fastening nut 5 is tightened, the pin pressing plate 3 is tightened by the rear top sleeve 4; the connection between the spline housing 1 and the pin pressing plate 3 Between the spline housing 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com