Chain transmission system

A technology of chain drive and sprocket, applied in the field of chain drive system, can solve the problems of high requirements on materials and heat treatment, high requirements on strength and wear resistance, and high manufacturing and use costs, so as to improve the transmission efficiency, improve the bearing capacity and structure. form a flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

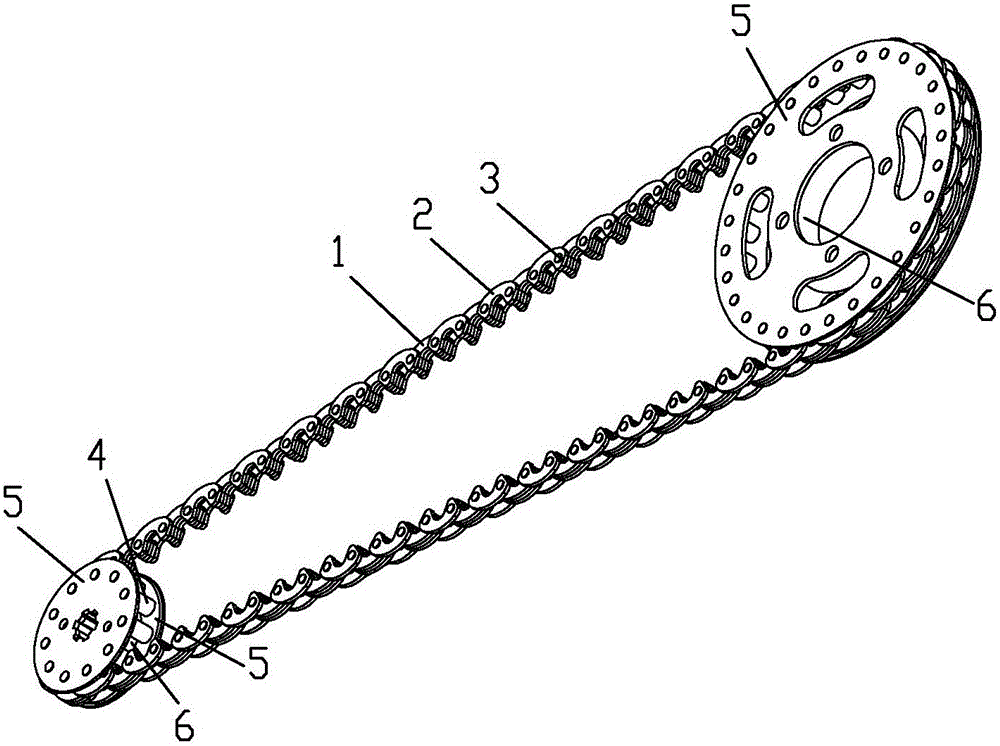

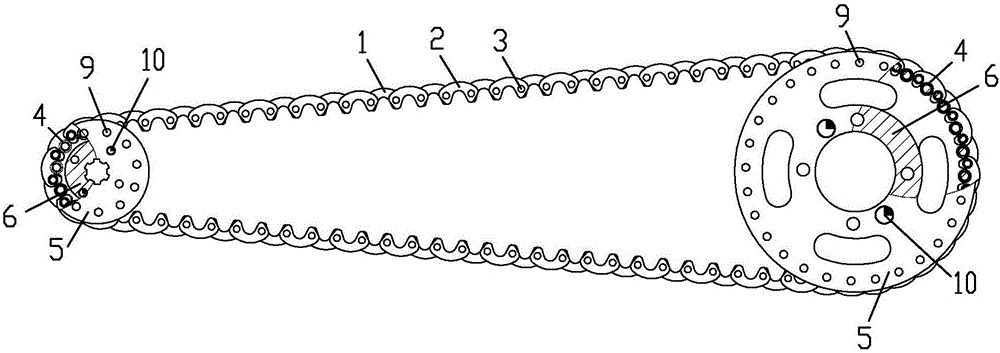

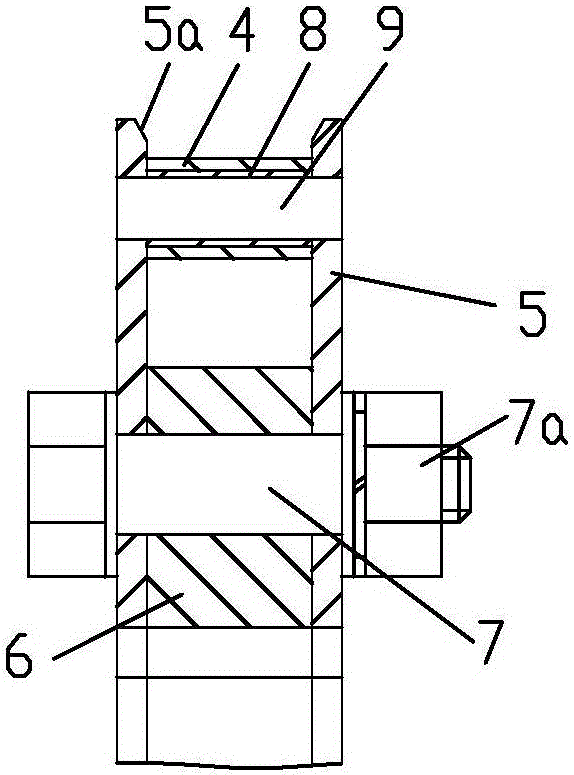

[0023] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , a chain drive system consisting of a figure 1 and figure 2 middle left drive sprocket, located in the figure 1 and figure 2 The driven sprocket on the right side of the middle, and the chain of the ring-shaped closed structure connected to the driving sprocket and the driven sprocket, the inner hole of the driving sprocket is a spline hole structure, and the driving sprocket and the driven sprocket include two The end disks 5 and the two end disks 5 are connected by the intermediate connecting cylinder 6 in the middle. Between the two end disks 5 on the outer periphery of the intermediate connecting cylinder 6, there are a plurality of rollers 4 forming sprockets evenly distributed on the circumference. The rollers 4 can be The rotating lining is lined with a sleeve 8, the sleeve 8 is set on the roller 9, and the two ends of the roller 9 are respectively fixed on the two end disks 5; the chain is compo...

Embodiment 2

[0028] Example 2, see Figure 5 , the head of the pin shaft 3 has a guide tapered surface 3b.

[0029] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com