Structure of solar battery module

A technology of solar cells and batteries, applied in the energy field, can solve problems such as battery string extrusion, battery string displacement, component scrapping, etc., and achieve the effect of reducing production losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structure of the solar cell module of the present invention will be further described in detail through specific examples below.

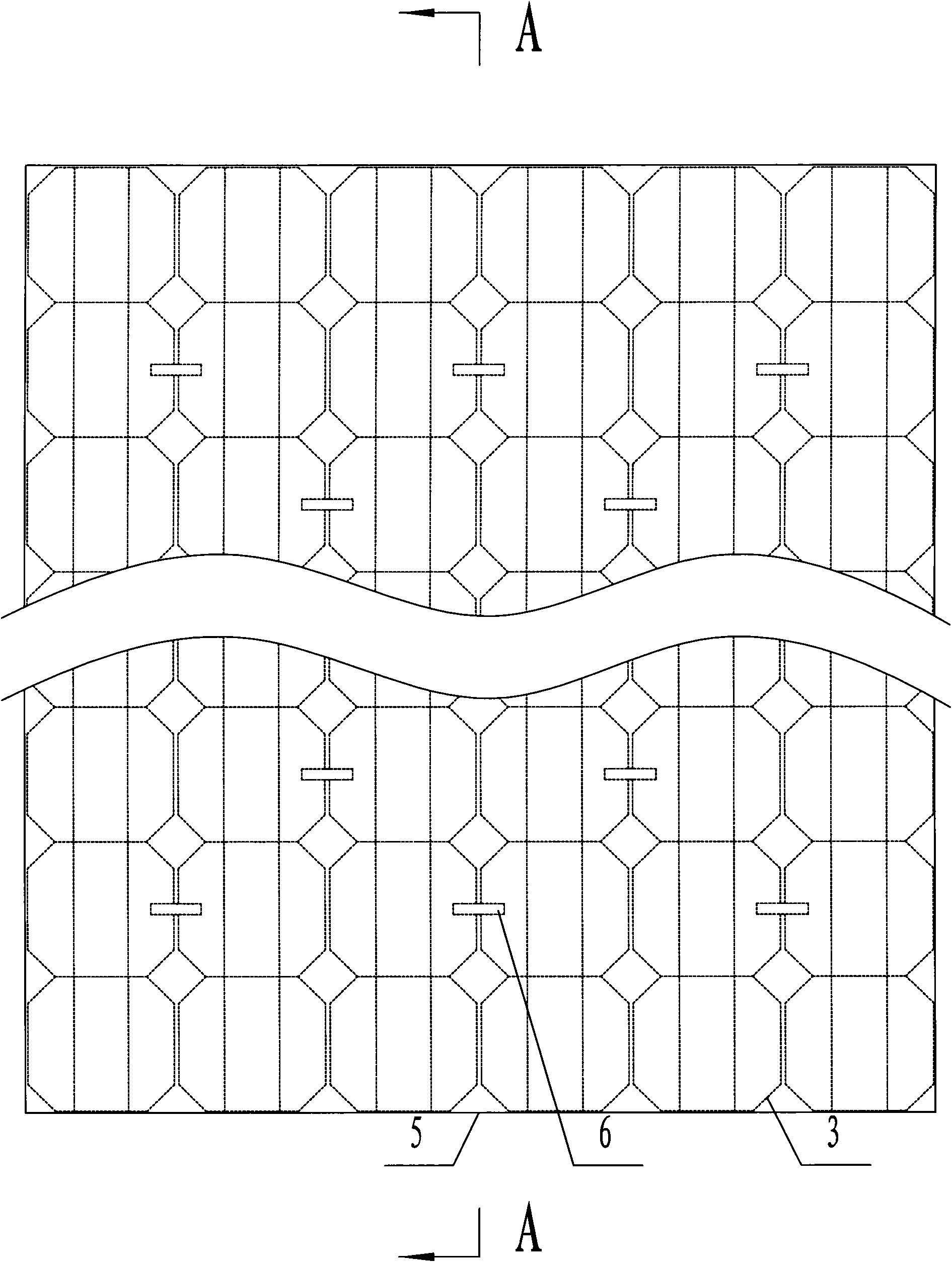

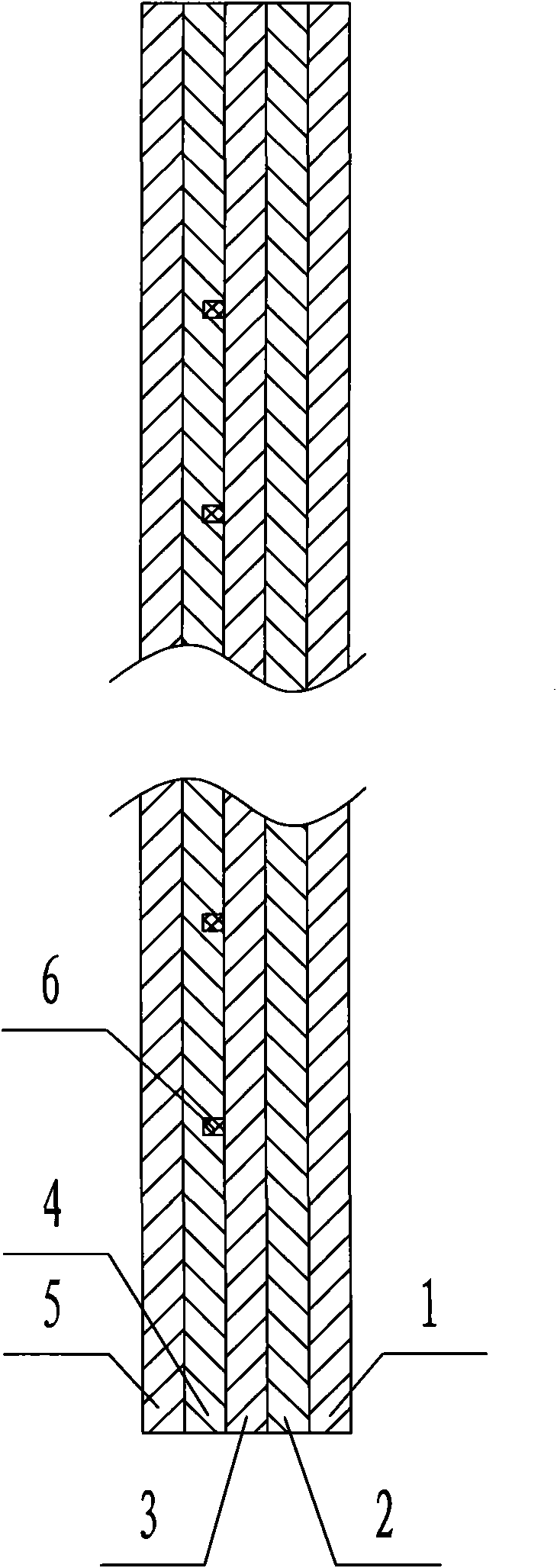

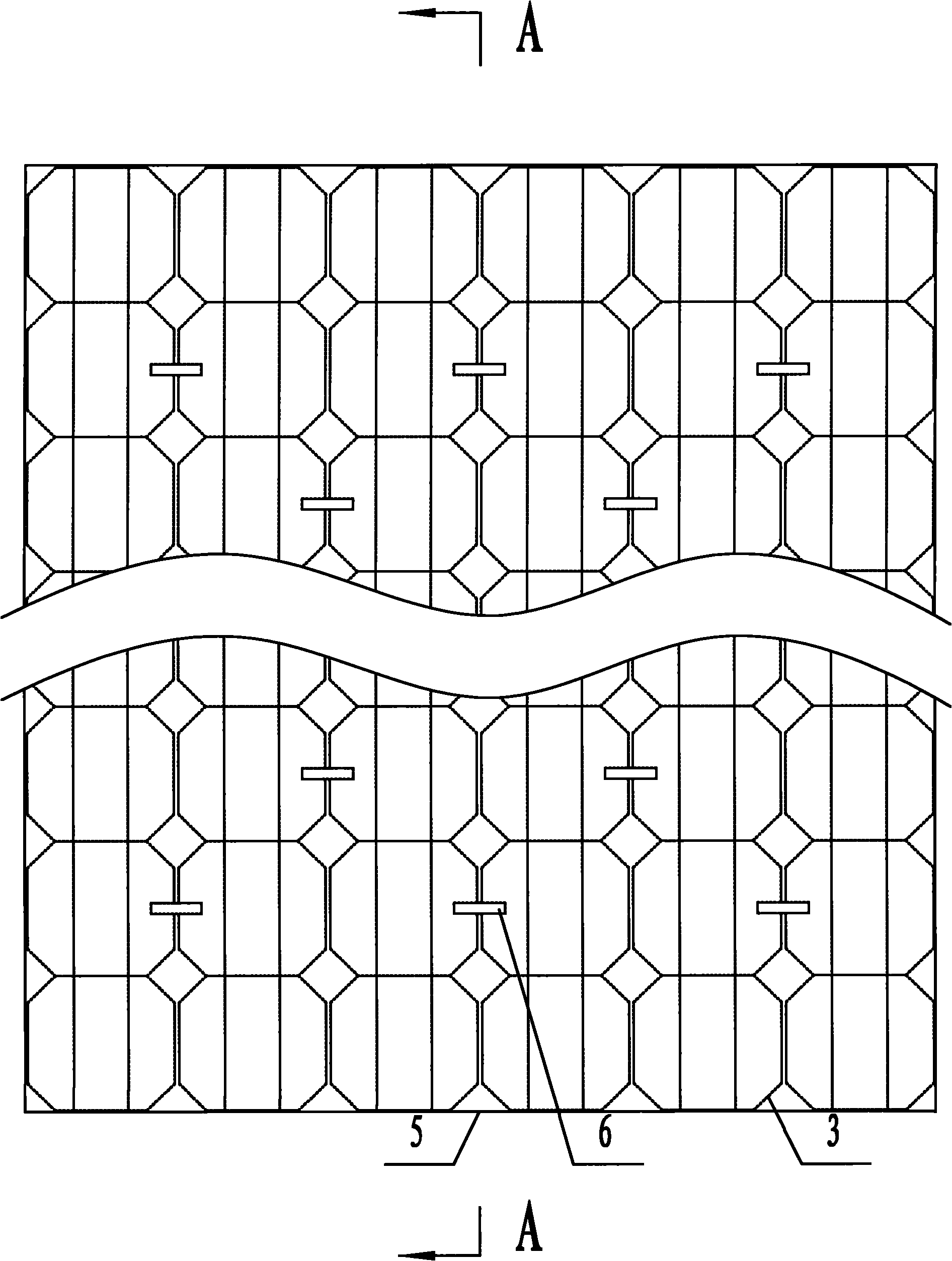

[0012] Such as figure 1 , figure 2 As shown, the structure of the solar cell module includes a back sheet 1 at the bottom, a lower EVA layer 2 above the back sheet 1, a battery string layer 3 above the lower EVA layer 2, and an upper EVA layer 4 above the battery string layer 3. Above the upper EVA layer 4 is a tempered glass layer 5 , and the battery string layer 3 includes several adjacently arranged battery strings, and two high-temperature fixing adhesive tapes 6 are overlapped at the front junctions of the adjacent battery strings. Alternatively, two high-temperature fixing adhesive tapes 6 may be overlapped at the junction of opposite surfaces of adjacent battery strings.

[0013] The beneficial effect of the present invention is: the solar battery module with the above structure is provided with a high-temperature fixing tape 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com