Deburring machine material grinding belt with replaceable polishing head

A deburring machine and grinding head technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve problems such as low grinding efficiency, achieve good applicability, save manufacturing costs, and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

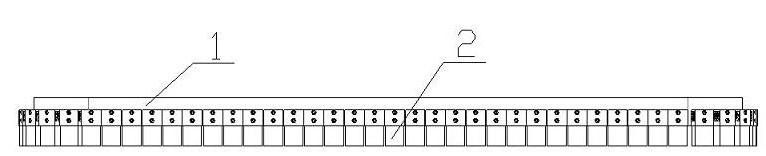

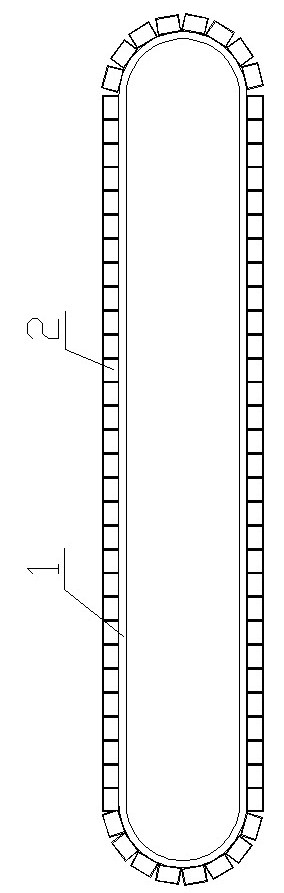

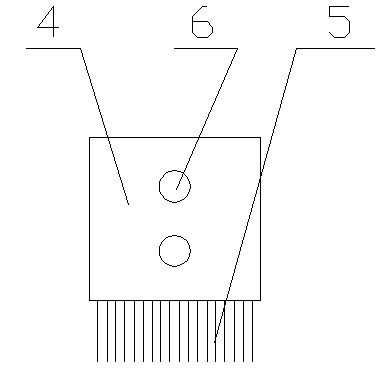

[0012] Embodiment 1: with reference to attached Figure 1-3 . An abrasive belt for a deburring machine with replaceable grinding heads, which includes an annular grinding base belt 1, and a plurality of grinding heads 2 are connected to the belt surface of the annular grinding base belt 1 at equal intervals or unequal intervals. The grinding head 2 is composed of a grinding head fixed body 4 and a deburring head 5 , and the deburring head 5 is fixedly planted on the grinding head fixing body 4 . The side of the grinding head 2 refers to the side of the fixing body 4 of the grinding head 2 .

[0013] The deburring head 5 is a metal wire deburring head, and the metal wire deburring head is composed of a plurality of steel wires.

[0014] The deburring head 5 is a non-metal wire deburring head, and the non-metal wire deburring head refers to a plurality of sand strips or a multi-layer sand belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com