Seven-axis turn-milling machining center

A compound machining center, turning and milling technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., to achieve the effect of prolonging service life, convenient maintenance, and small loss of transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

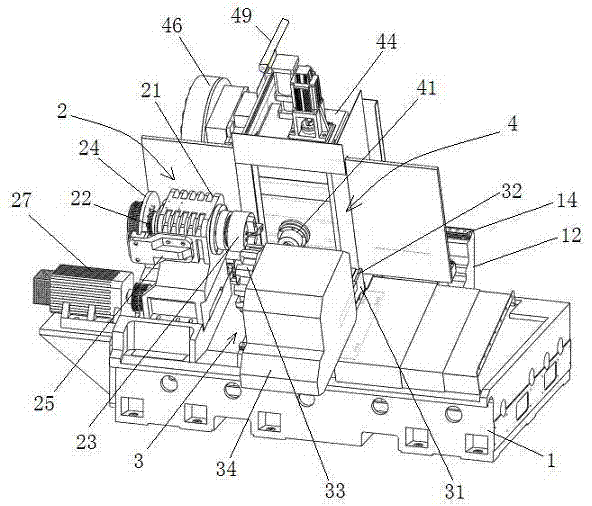

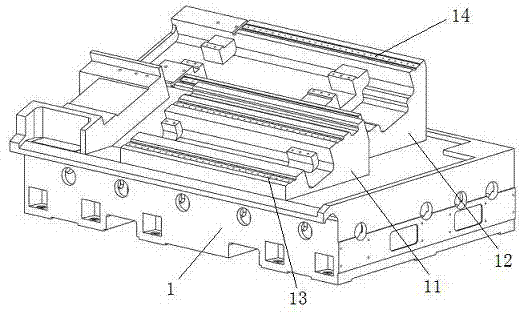

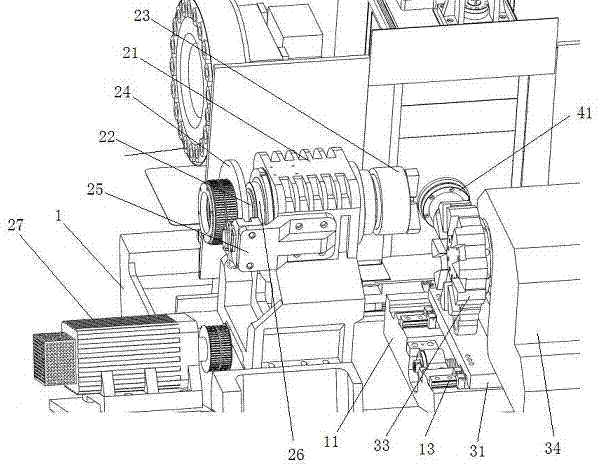

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 The seven-axis turning-milling compound machining center shown includes a base 1 and a bed set on the base 1, the bed is composed of a slanted bed A11 and a slanted bed B12 arranged side by side, and the slanted bed A11 The upper surface of the inclined bed A11 and the inclined bed B12 are inclined to the same side, and the upper surfaces of the inclined bed A11 and the inclined bed B12 are respectively provided with X-axis A guide rail 13 and X-axis B guide rail 14 parallel to each other; it also includes workpiece clamping Device 2, turning device 3 and milling device 4;

[0029] The workpiece clamping device 2 includes a spindle box 21 connected to the same end of the inclined bed A11 and the inclined bed B12 at both ends of the bottom, and a spindle 22 connected to the spindle box 21. The spindle hole of the spindle box 21 has interference A shaft sleeve 26 is connected, and the main shaft 22 is rotatably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com