Ultrasonic-modulation electrostatic-induction-drive fine electric spark machining device

An electrostatic induction and processing device technology, applied in electric processing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing processing speed, limiting micro-EDM machining, and difficulty in discharging waste, so as to improve chip removal and realize micro-processing. The effect of EDM

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

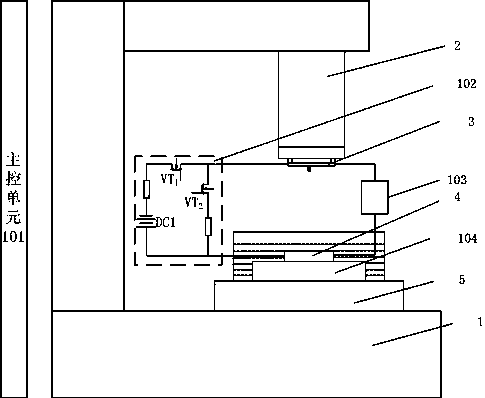

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] Figure 1 to Figure 10 The reference numerals in the figure are: machine tool body 1; Z-axis lifting and feeding mechanism 2; metal sheet 3; workpiece fixture 4; XY motion platform 5; ultrasonic transducer 6; trigger 7; exclusive OR gate 8; comparator 9 ; optocoupler 10; NAND gate 11; data selector 12; main control unit 101; power supply 102; inter-electrode discharge detection circuit 103; ultrasonic vibration and detection device 104;

[0030] Such as figure 1 shown to Figure 10 , a micro electric discharge machining device driven by ultrasonic modulation electrostatic induction, including a main control unit 101, a machine tool body 1 and a power supply 102, etc., the machine tool body 1 is preferably granite, and the machine tool body 1 is provided with a workbench and The Z-axis lifting and feeding mechanism 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com