Vertical plate feeding numerical control drill with routing

A kind of engraving and milling and vertical technology, which is applied in the field of vertical board feeding CNC drilling, can solve the problems of difficult personalized product production, no engraving and milling, and inability to meet the requirements of workpiece appearance design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

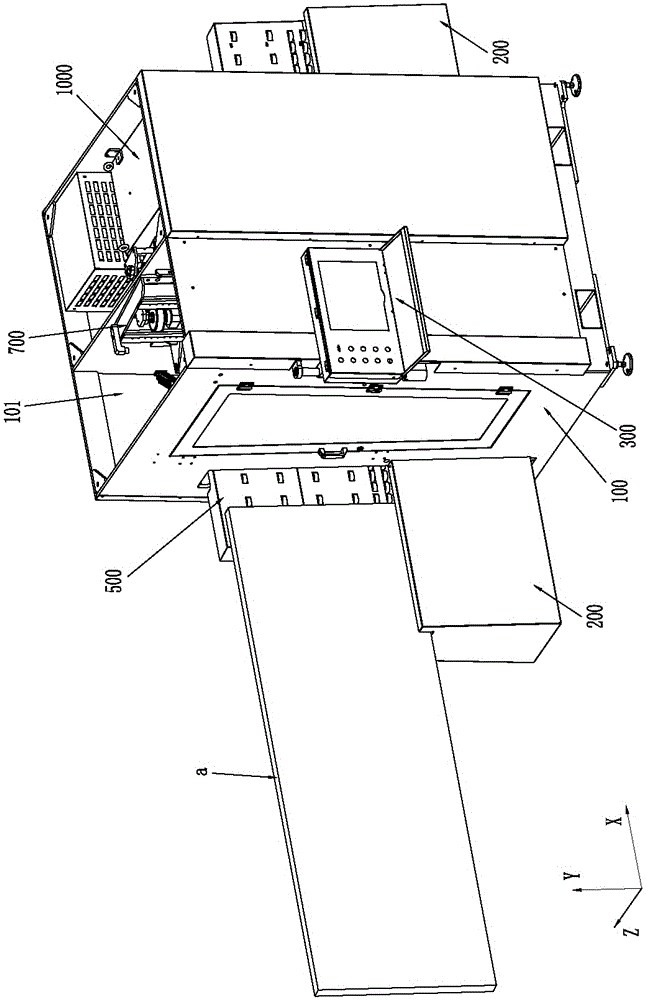

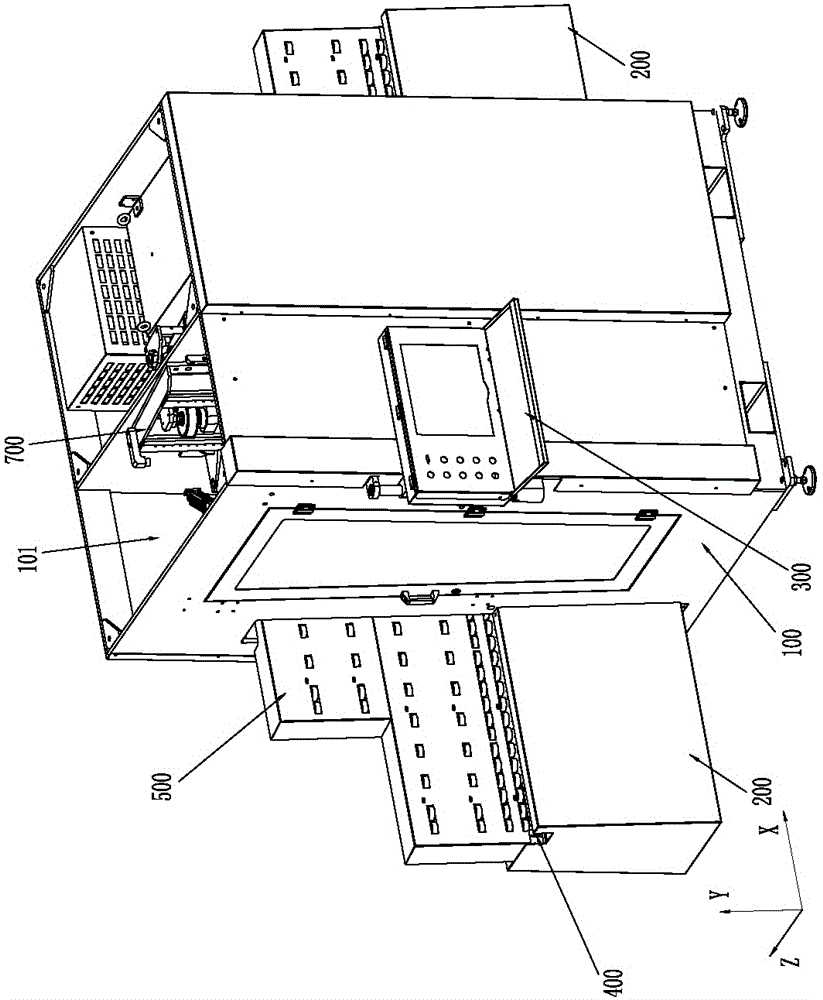

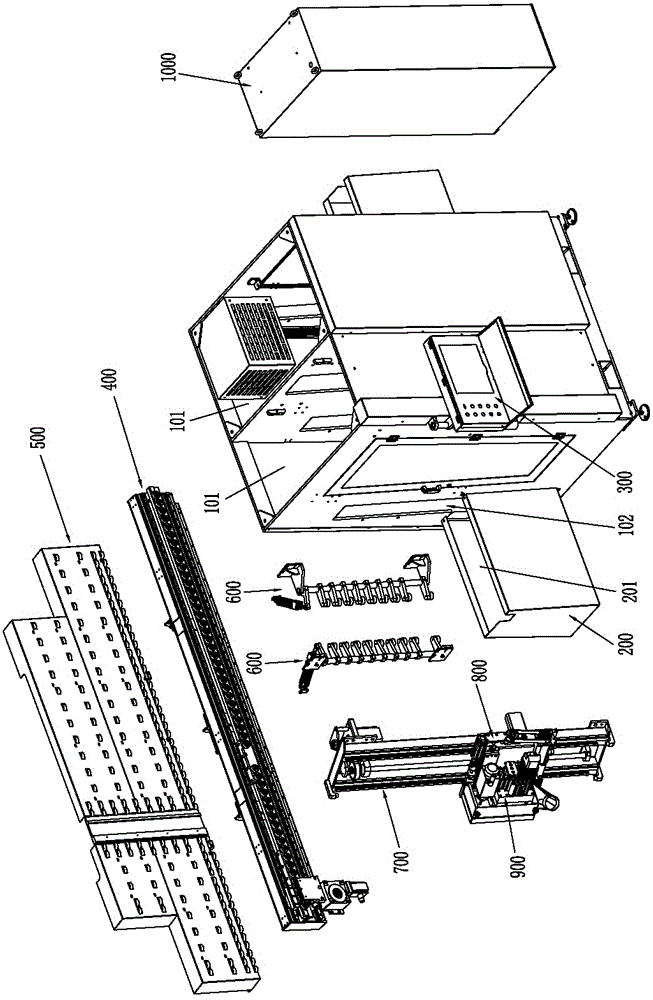

[0099] Please refer to Figure 1 to Figure 23 Shown, it has shown the concrete structure of the embodiment of the present invention;

[0100] The vertical plate feeding CNC drill with engraving and milling includes a frame part 100, an X-axis part 400, an inclined plate part 500, a pressing plate part 600, a Y-axis part 700, a Z-axis part 800, a drill box part 900, and an electric box part. 1000 and the operation panel part 300; wherein, the X-axis is arranged horizontally, the Y-axis is arranged vertically, and the Z-axis is arranged horizontally and respectively perpendicular to the X-axis and the Y-axis, such as Figure 1 to Figure 5 As shown, it is a vertical feeding of the plate a, and the drilling box part 900 is set as a horizontal type, that is, the drilling box and milling cutter are horizontally fed;

[0101] The frame part 100 includes a box body, a housing cavity 101 is formed in the box body, and a main channel 102 penetrating both sides of the box body along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com