Numerical control center sill combined drilling machine

A combined drilling machine and CNC spindle technology, applied in the parts of boring machine/drilling machine, drilling repair, drilling tool accessories, etc., can solve the problem of difficulty in guaranteeing tool durability, and achieve the effect of advanced tool selection, good workmanship and advanced structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

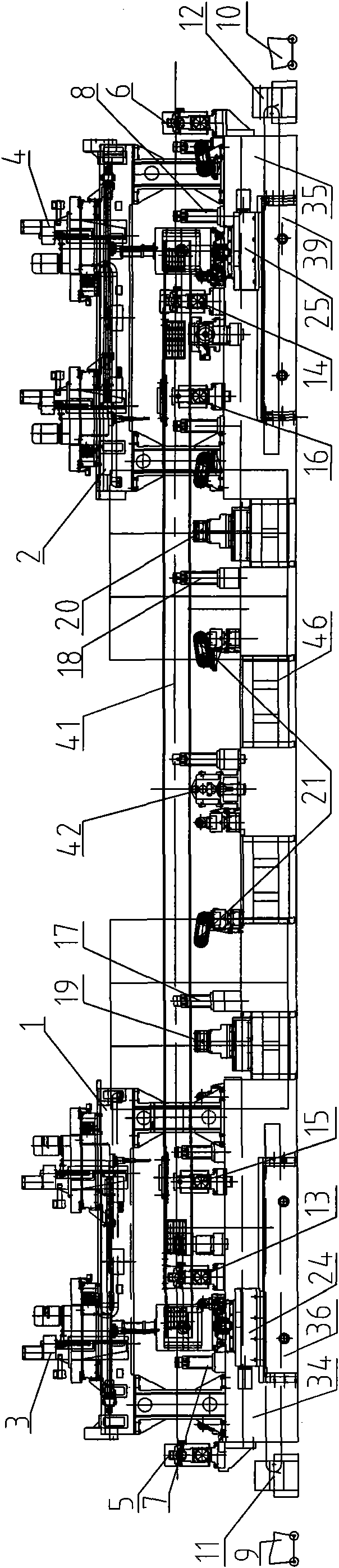

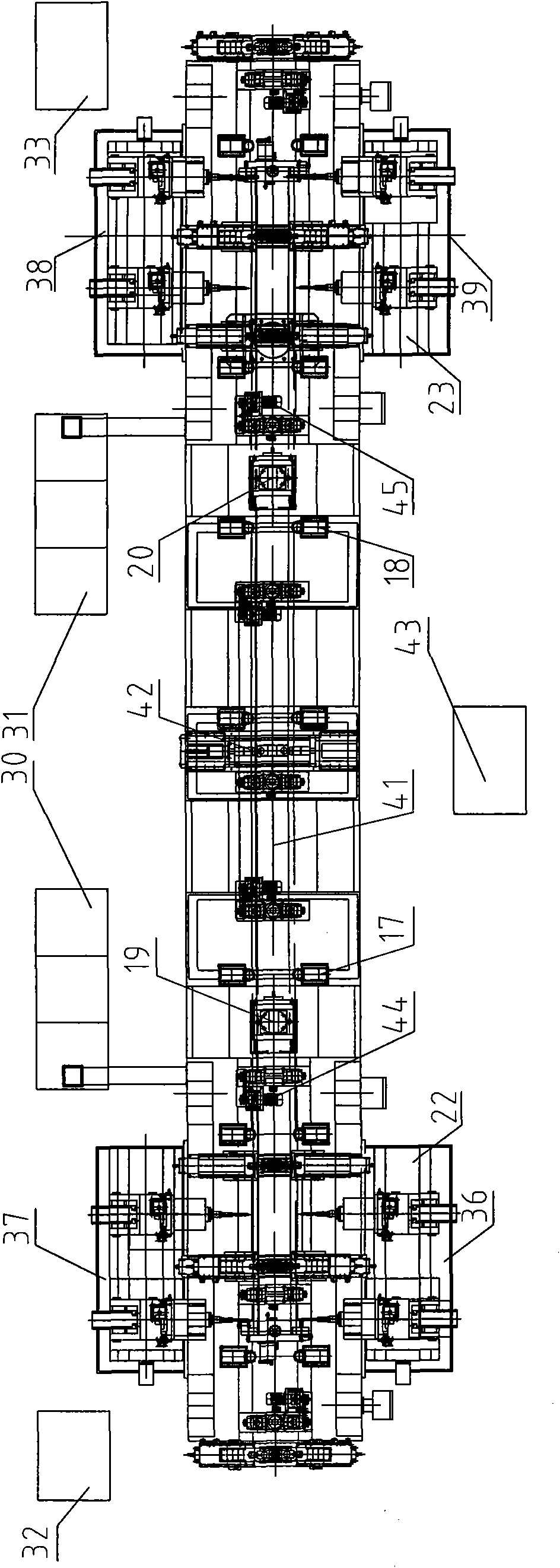

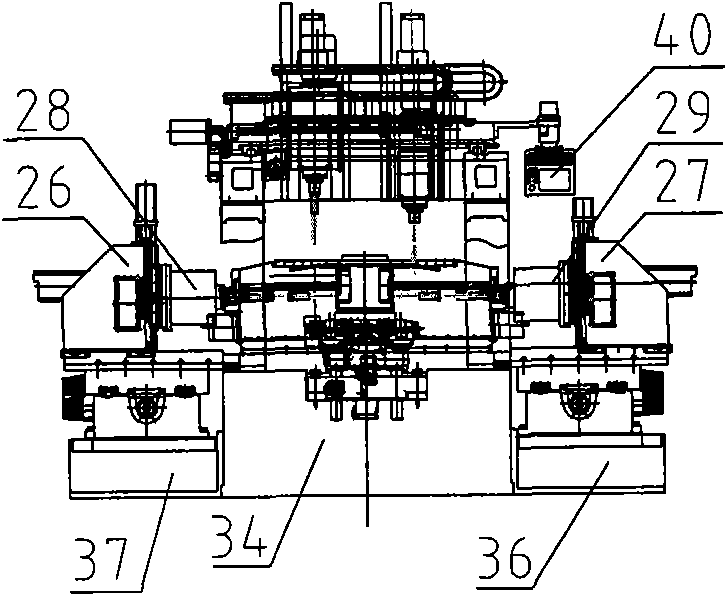

[0047] Such as Figure 1~5 As shown, the vertical ends of the machine tool of the present invention are arranged symmetrically at both ends. The present invention mainly includes the following structure: left gantry main body 1, right gantry main body 2, left vertical head CNC spindle box unit 3, right vertical head CNC spindle box unit 4, special-shaped Fixtures 5, 6, terminal fixtures 7, 8, chip boxes 9, 10, chip conveyors 11, 12, main fixtures 13, 14, auxiliary fixtures 15, 16, lateral guide wheels 17, 18, fine feed mechanisms 19, 20 , 21 is the feedway conveying mechanism composed of conveying rollers No. 1 to No. 11, which is used for the input and output of the center beam, and four sets of 80-specification Z-axis CNC slide tables 22 and 23 are used for processing 15 groups of holes and 12 on the side of the center beam. Horizontal coordinate position and rapid movement of the group hole system, four sets of horizontal X-axis CNC sliding tables 24, 25, used for drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com