Reamable rotatable grabbing bucket device and using method thereof

A grab and deviation correction device technology, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of uncontrollable verticality of walls, easy burial of grabs, and high construction costs problems, achieve the effect of reducing the depth of the wall, improving the bearing capacity of the wall, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

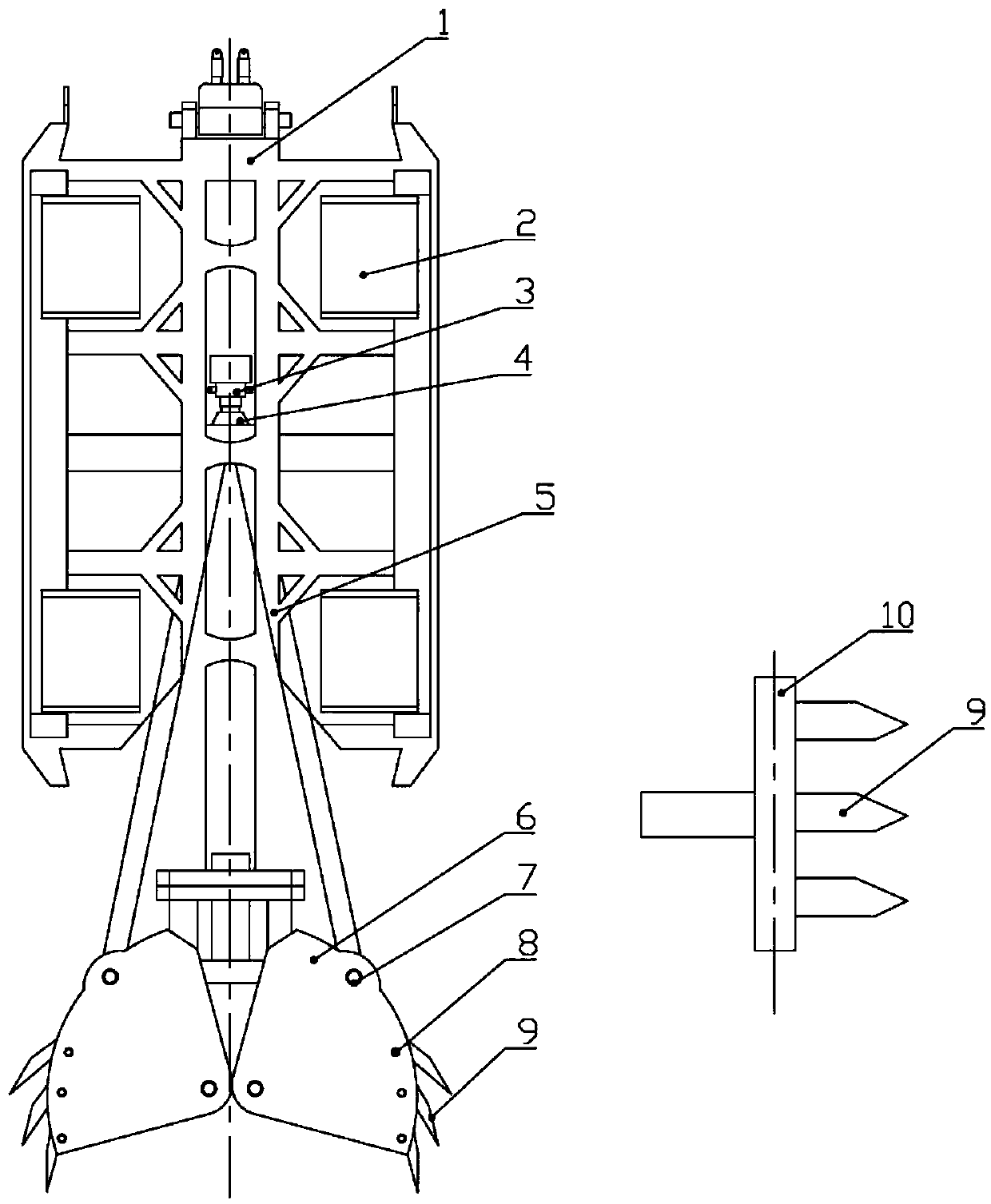

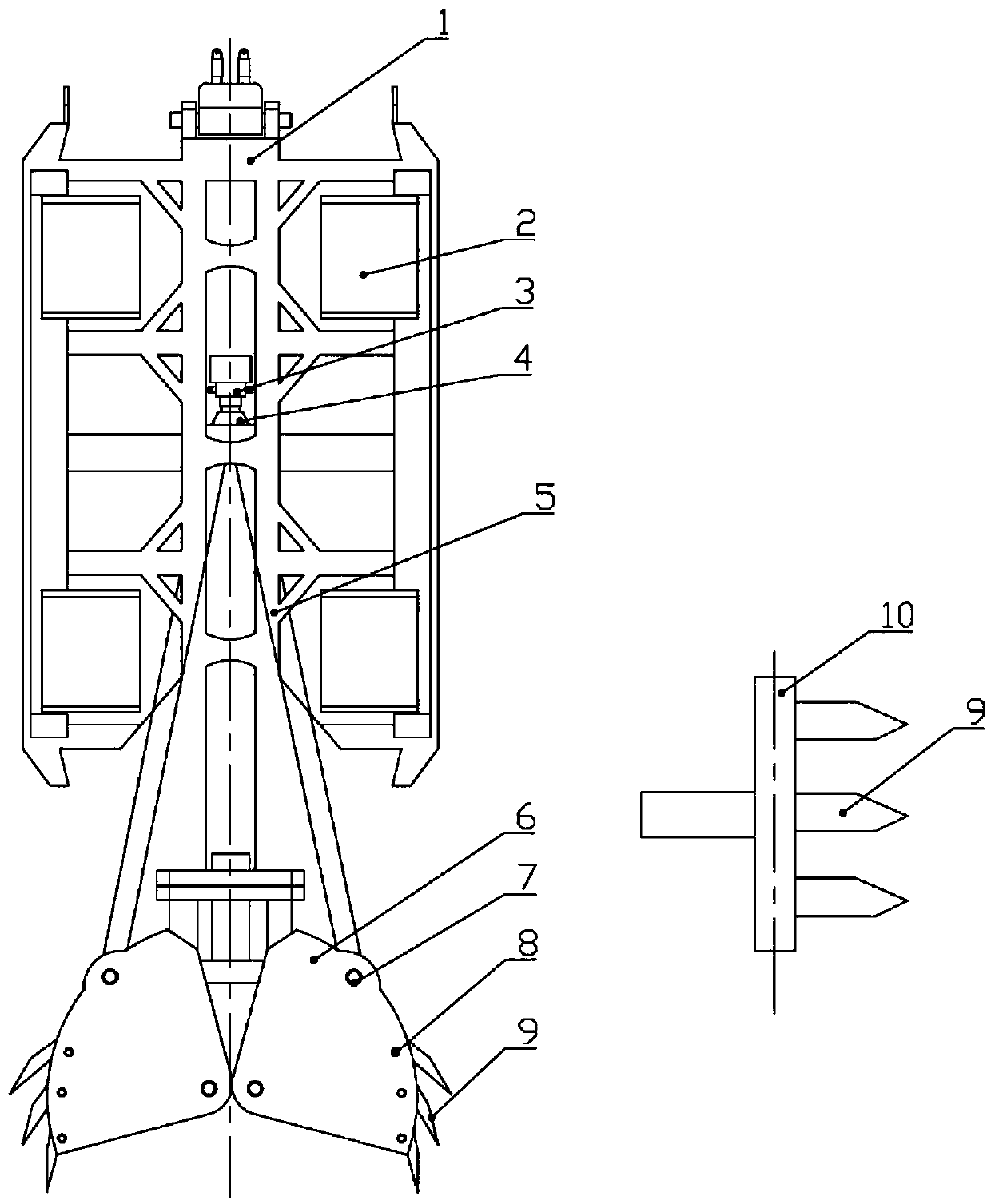

[0026] Such as figure 1 As shown, a reamable and rotatable grab device 12 and its use method, the device mainly includes a grab bracket 1, a deviation correction device 2, a hydraulic rotary motor 3, a jacking cylinder 4, a connecting rod 5, and a square bucket 6 , square bucket pin 7, plate tooth pin shaft 8, plate tooth 9, plate tooth sleeve 10. The deviation correction device 2 is arranged on the grab bracket 1, the hydraulic rotary motor 3 is installed at the middle position of the grab bracket 1, the jacking cylinder 4 is connected with the hydraulic rotary motor 2, and one end of the connecting rod 5 is connected to the jacking bracket 1. The oil cylinder 4 is connected, the other end is connected with the square bucket 6 respectively, and the die sleeve 10 is connected, and the die 9 is embedded on the die sleeve 10 .

[0027] A reamable and rotatable grab device is used as follows:

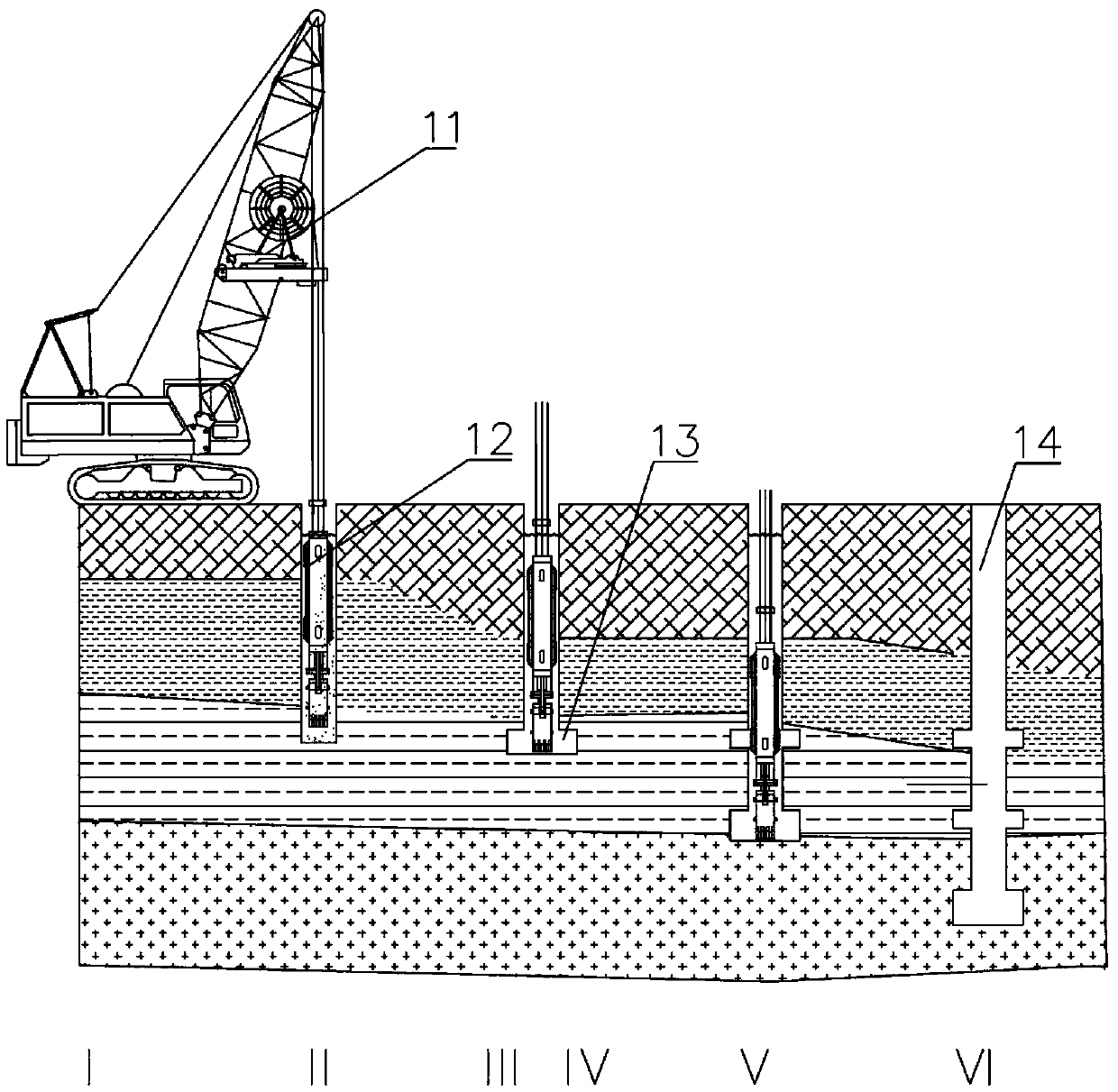

[0028] 1. The slotting machine 11 is in place, and the reamable and rotatable grab d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com