Laser plumb line measuring device and laser plumb line measuring system

A measuring device and laser technology, applied in the field of construction and installation, can solve the problems of affecting adjustment speed, affecting construction efficiency, low degree of automation, etc., and achieve the effect of ensuring verticality accuracy, improving operation efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

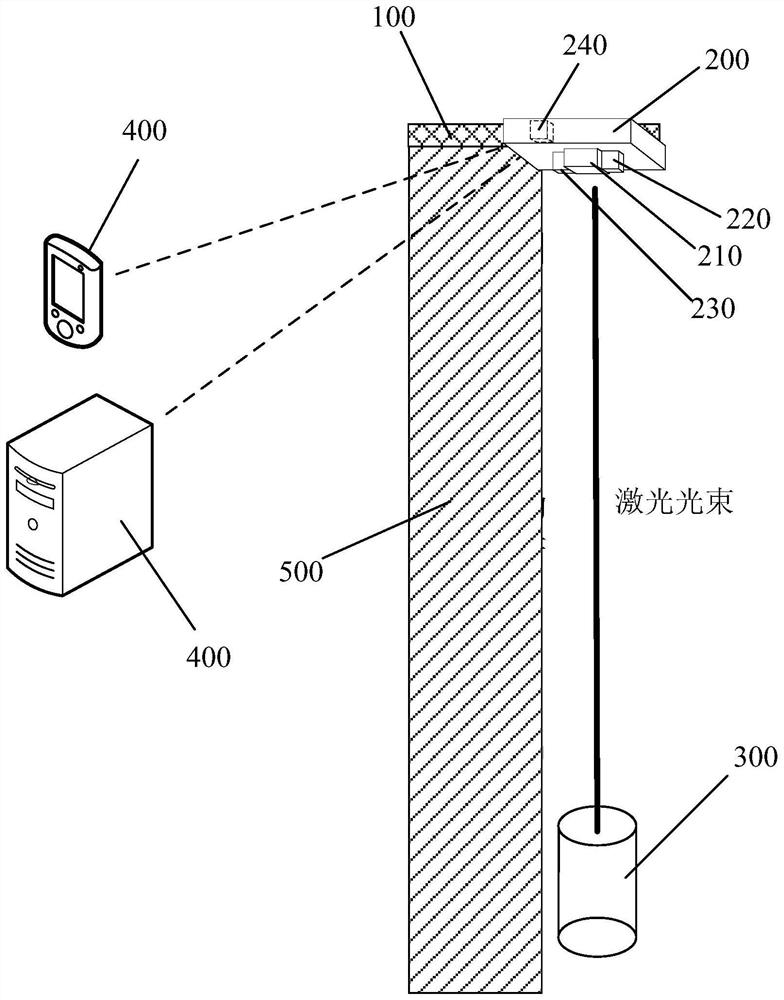

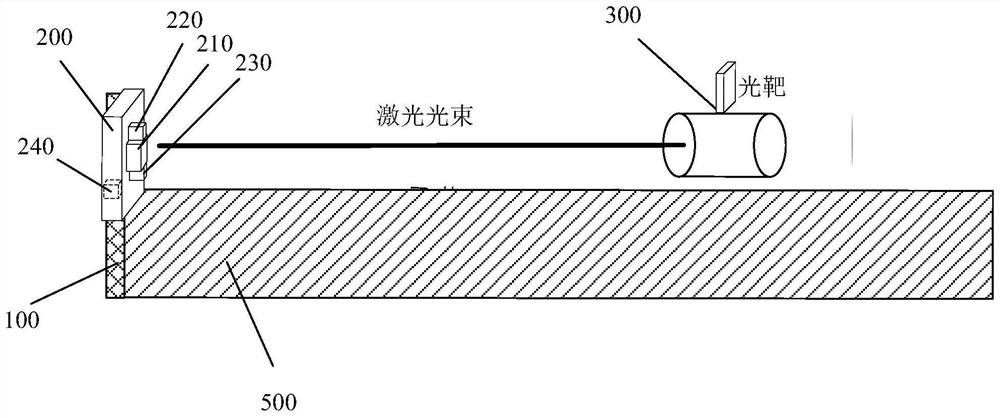

[0067] Such as figure 2 As shown, it is a schematic structural diagram of the installation surface of the laser vertical line measuring device 200 adjusted on the ground. Usually there are two types of column 500, square lattice column and circular steel pipe column. Under the recumbent state of these two kinds of columns 500, the laser vertical line measuring device 200 can be installed on the adjustment bracket 100 first, and then the adjustment bracket 100 can be fixedly installed on the top of the column 500; by adjusting the bracket 100, the direction of the laser beam can be adjusted so that The laser two-dimensional meter automatically measures the laser spot position value or the spot position manually measured by the light target, and keeps consistent at different positions of the column 500. At this time, it can be determined that the laser is parallel to the axis of the column 500. When the laser vertical line measuring device 200 emits the laser The light beam is...

Embodiment 2

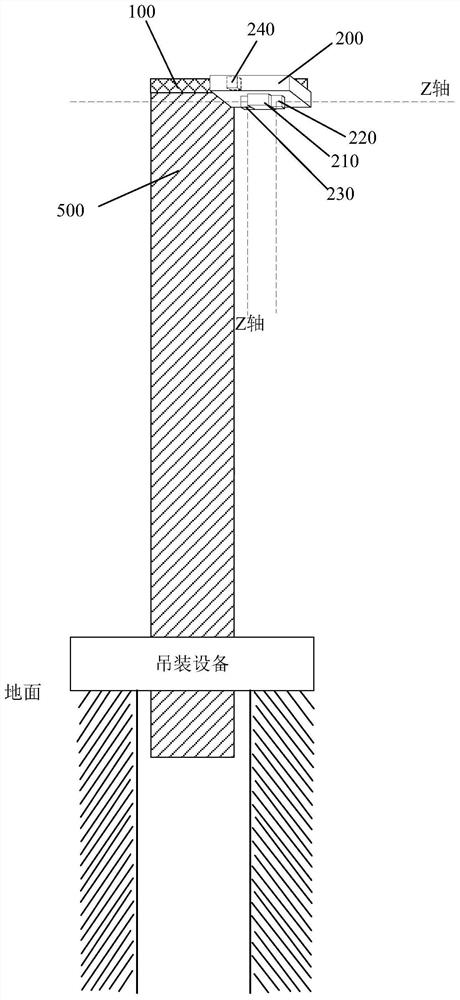

[0070] Such as image 3 As shown, it is a schematic structural diagram when the column 500 is hoisted and installed in the well. When the column 500 is hoisted and lowered into the well (hole), for example, when the column 500 is in a completely vertical state, the horizontality measurement value output by the laser vertical measuring device 200 should be 0 degrees. It should be noted that the laser beam of the laser vertical line measuring device 200 has been calibrated to be coaxial or parallel to the column 500 at this time, therefore, the laser beam can be turned off when the column 500 is hoisted, and the main three-axis tilt sensor 220 and the auxiliary three-axis tilt sensor 220 The inclination sensor 230 collects three-axis direction measurement data (perpendicularity value or horizontality value) measured in real time to guide the vertical hoisting of the column 500 . During the actual installation process, generally the column 500 will be in a tilted state. At this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com