Pouring system and lining trolley

A supporting frame and lower layer technology, applied in shaft lining, tunnel lining, underground chamber, etc., can solve problems affecting construction efficiency, grout leakage, and difficulty in guaranteeing lining quality, so as to ensure lining quality and reduce manufacturing costs , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

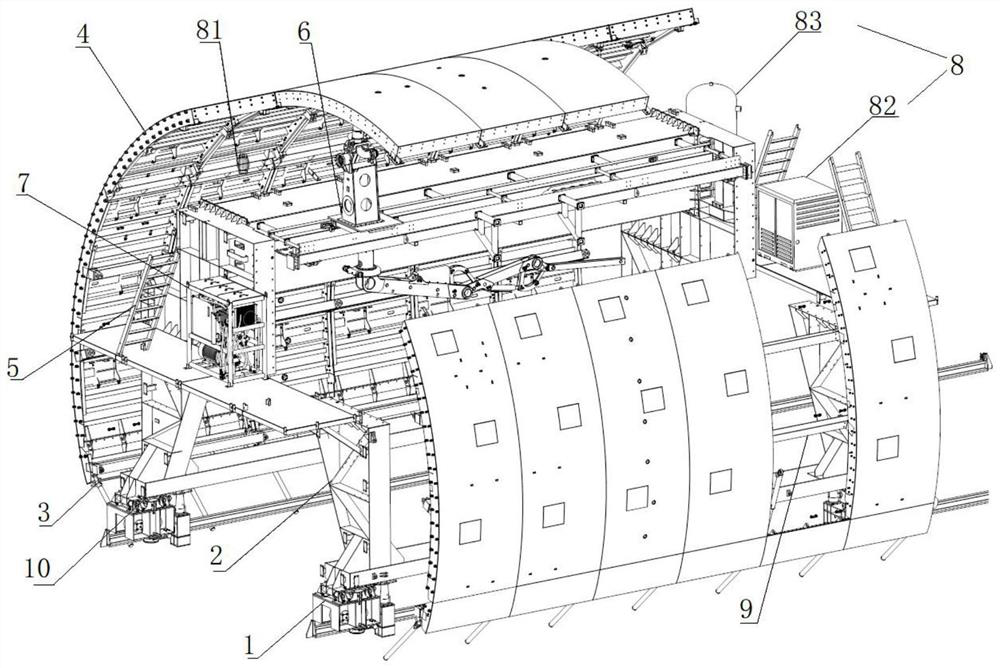

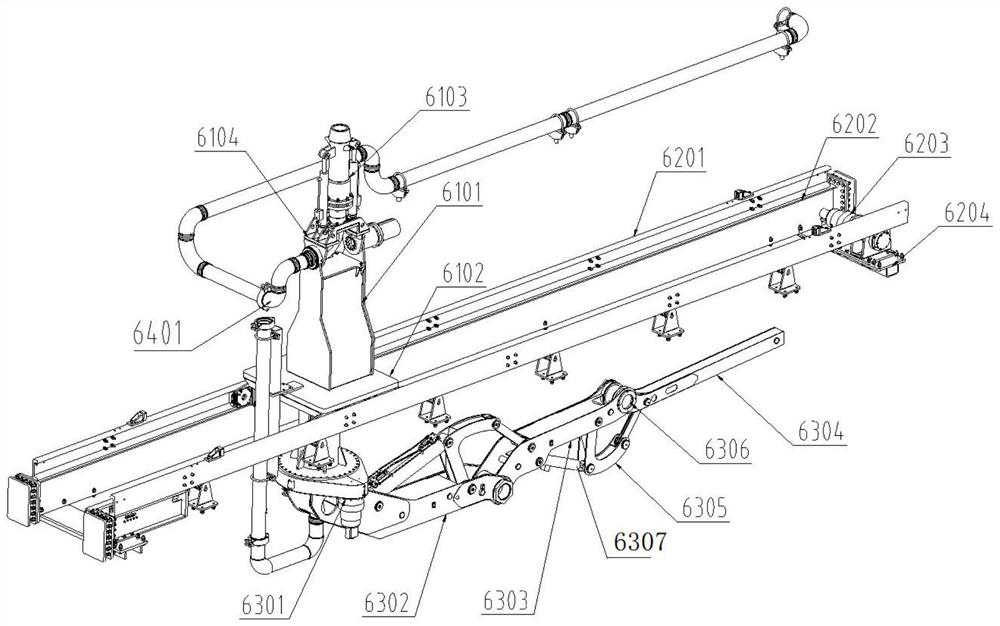

[0035] see Figure 1-4 , a lining trolley, including a walking system 1, a gantry system 2, a support system 3, a formwork system 4, a vibrating system 8 and a pouring system 6, the walking system 1 is arranged at the lower part of the gantry system 2, the The formwork system 4 is set on the gantry system 2 through the support system 3 , and the pouring system 6 is set at the middle position on the upper part of the gantry system 2 .

[0036] The walking system 1, the gantry system 2, the support system 3 and the formwork system 4 are all prior art. In the present embodiment, the gantry system 2, the support system 3 and the formwork system 4 are briefly described as follows:

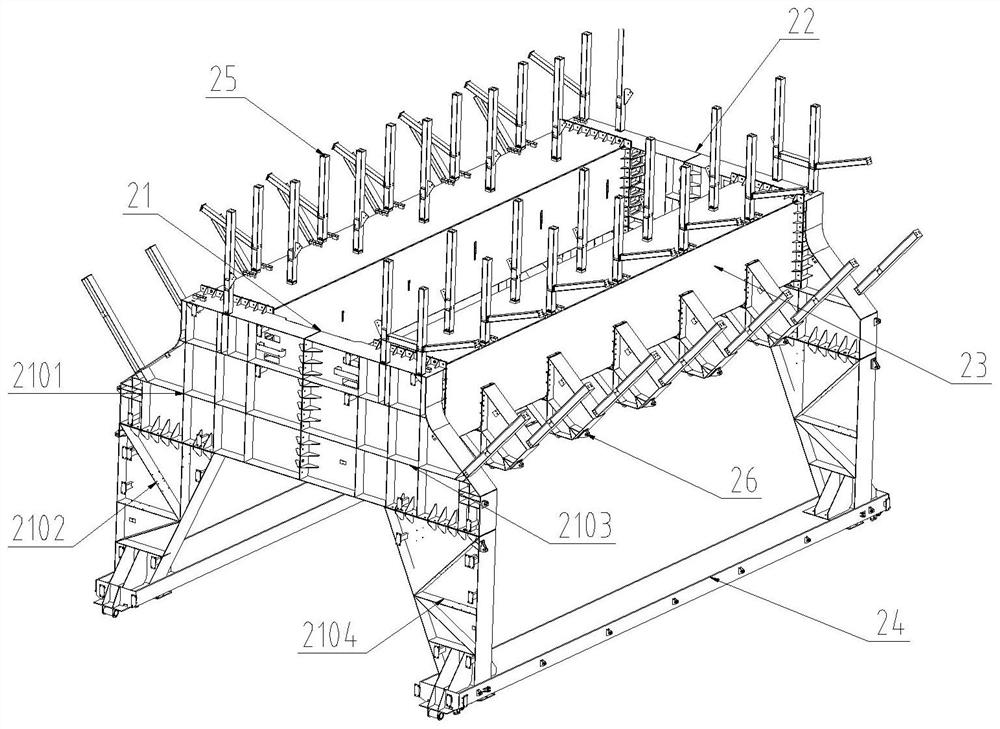

[0037] see image 3 , the mast system 2 includes a front mast assembly 21, a rear mast assembly 22, a mast connecting beam 23 and a mast lower longitudinal beam 24; the front mast assembly 21 includes a left upper mast 2101, a left lower mast 2102, a right upper door frame 2103, right lower door frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com