Lining building machine

A lining machine and vibrating motor technology, applied in irrigation pipelines, applications, construction, etc., can solve problems such as difficult to ensure the compaction effect, and achieve the effects of simple structure, guaranteed lining quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

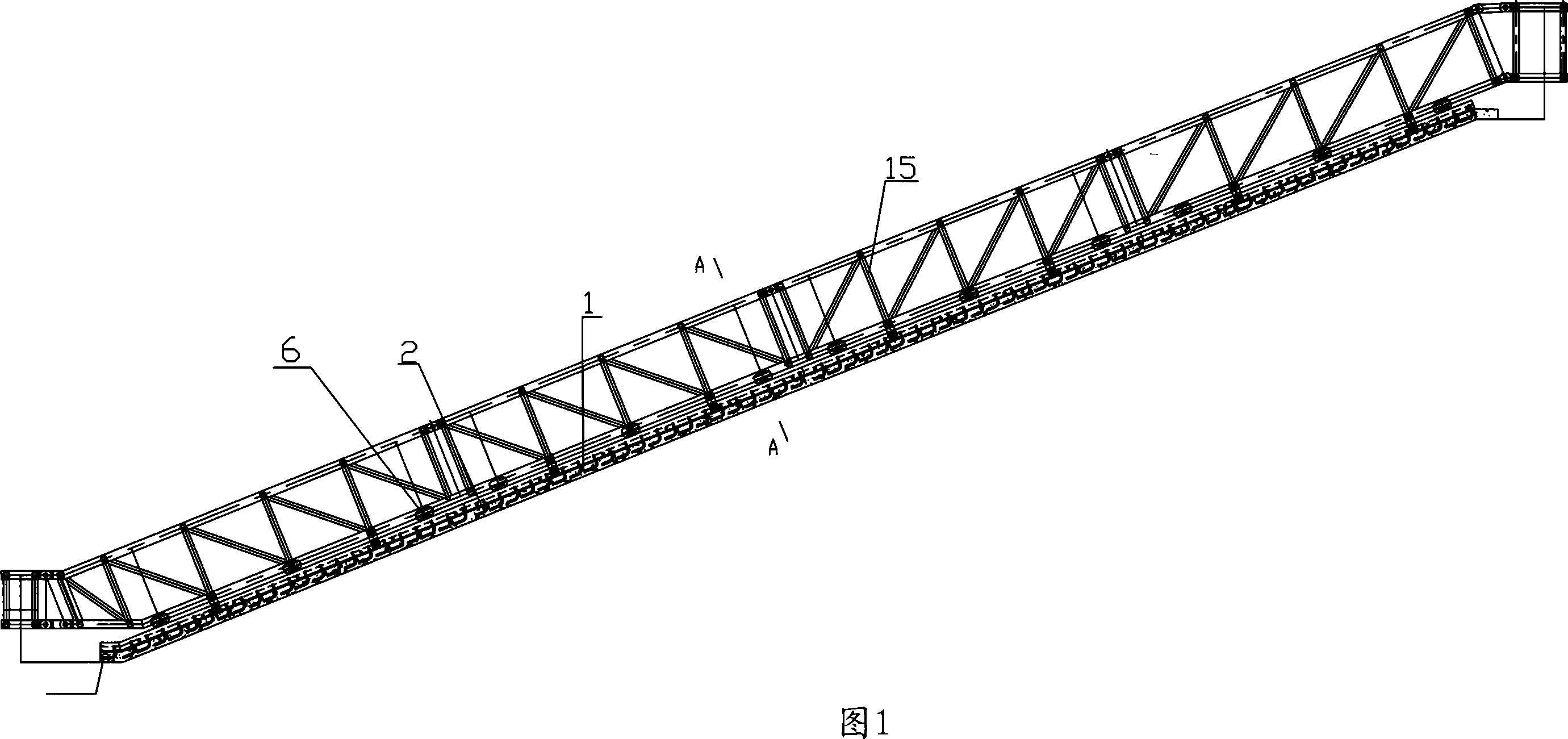

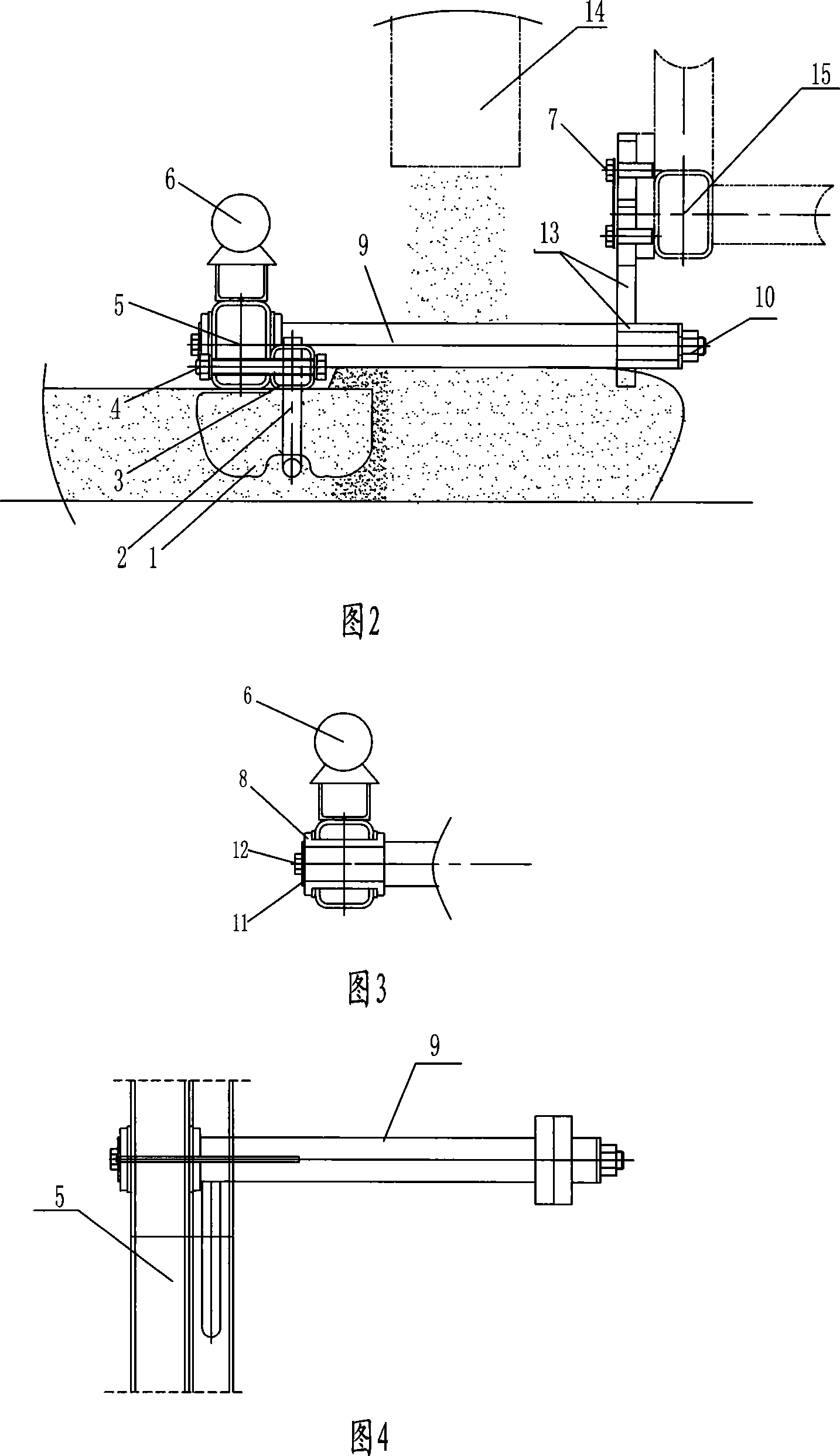

[0014] As shown in the figure, this embodiment includes a main frame 15 and a distribution cart installed on the main frame 15. A vibrating and smoothing mechanism is arranged below the discharge port 14 of the distribution cart. This embodiment is installed along the length of the main frame 15. There are 12 groups of vibrating and smoothing mechanisms. The mechanism is mounted on the main frame 15 via an adjustable support plate 13 . One end of the support rod 9 is installed on the adjustable support plate 13 , and the adjustment of the distance between the end and the main frame 15 is realized by the adjustable support plate 13 or its connection with the adjustable support plate 13 . Its structure can adopt the prior art. The other end of the support rod 9 is connected with the vibrating beam 5 through the shock absorber 8 . The vibrating beam 5 is strip-shaped, and it is perpendicular to the moving direction of the equipment, and plays a smoothing effect during equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com