Construction Method of Grouting with Formwork on Tunnel Vault

A technology of grouting and vaulting, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of high construction cost, serious shrinkage, low strength, etc., to reduce the risk of disasters, improve immunity, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

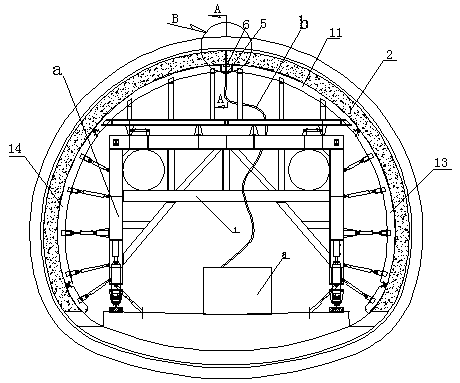

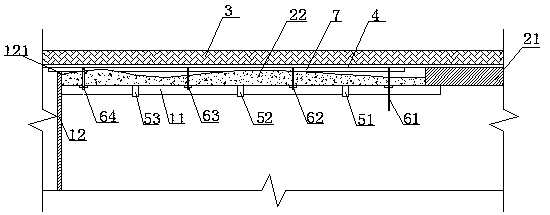

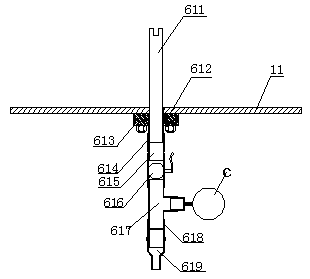

[0017] given in the present invention figure 1 , figure 2 , image 3 In the embodiment, channel steel and metal plates are welded into the frame of the lining platform, and the jacks 15, the vault formwork 11, the left arch wall formwork 14, and the right arch wall formwork 13 are combined and installed on the lining platform frame, and the vehicle frame The rollers installed at the bottom are located on the track of the ground platform in the tunnel to form the tunnel lining construction lining trolley a. After the lining trolley a is installed in the excavated tunnel and fixed in place, the integrated grouting machine 8 is placed on the ground at the bottom of the lining trolley a, and the two ends of the delivery hose b are respectively connected to the reducing pipe joint 619 and On the mouth of the grout outlet of the integrated grouting machine.

[0018] 3 concrete pouring holes 5 with the same structure and 4 circular holes with the same structure are arranged at eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com