An adhesive water-based fire extinguishing agent for vertical solid fires

A technology of fire extinguishing agent and vertical surface, which is applied in the field of adhesive water-based fire extinguishing agent, which can solve the problems of increased fire extinguishing time, large amount of fire extinguishing agent used, and increased possibility of flame spread, so as to increase the adhesion rate and reduce the risk of disasters degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

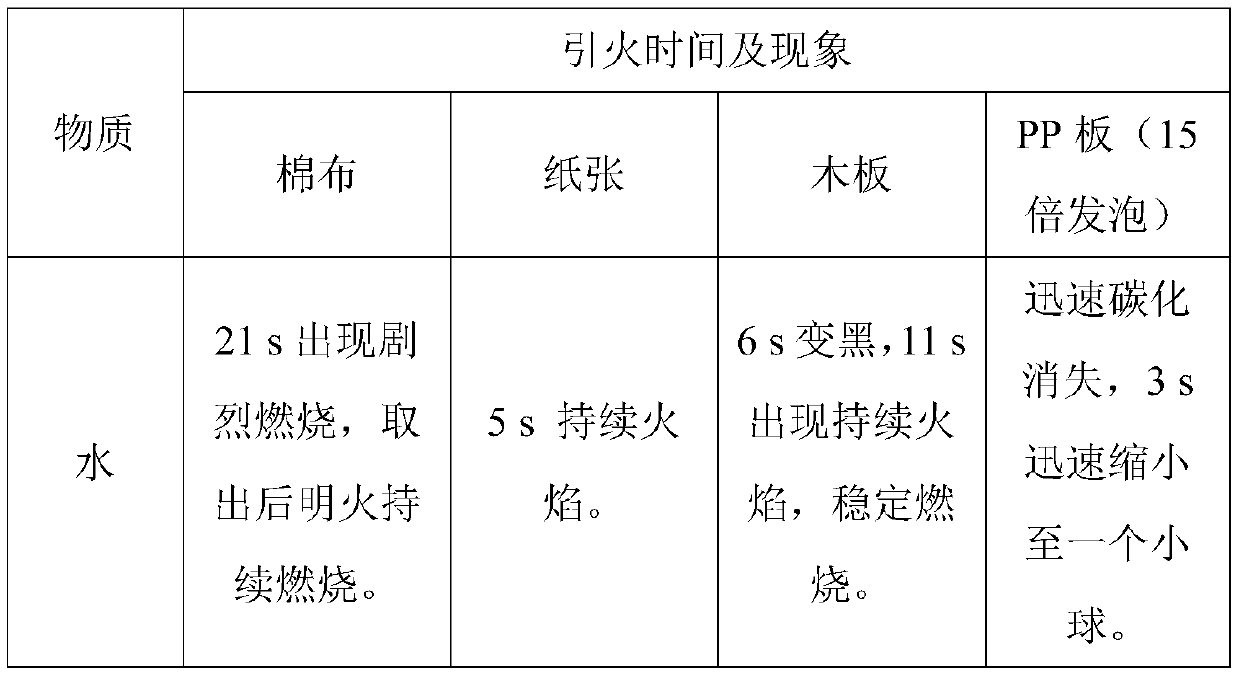

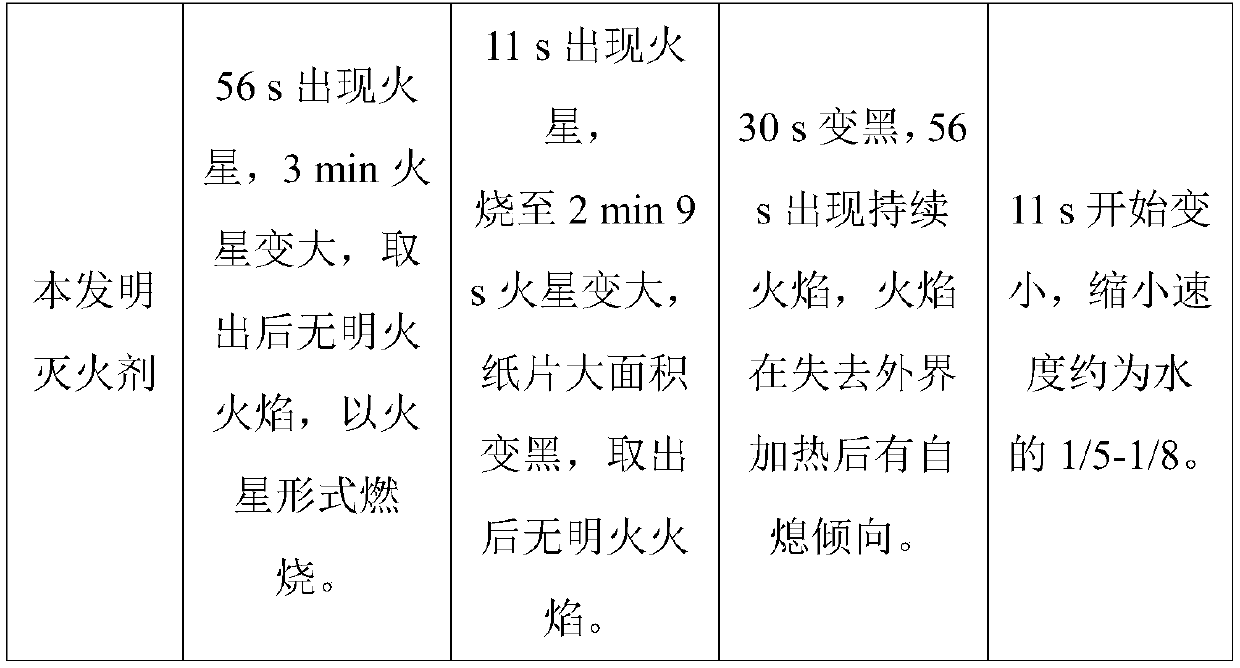

[0036] Observe the time and phenomenon of the fire extinguishing agent being ignited by the surrounding fire after it is attached to the combustible material, so as to infer its ability to prevent the high temperature ignition of the surrounding fire after it is sprayed on the burning material.

[0037] Use the recipe for

[0038] Potassium bromide: 5%; (mass percentage)

[0039] Tween-80: 0.1%; (mass percentage)

[0040] Sodium carboxymethyl cellulose: 2%; (mass percentage)

[0041] Sodium silicate: 2%; (mass percentage)

[0042] Sodium polyacrylate: 1%; (mass percentage)

[0043] Disodium edetate: 0.2% (mass percentage)

[0044] The balance is water.

[0045] Using an alcohol flame as the ignition source, the flame can coat the material for combustion. Soak each material in water and in the fire extinguishing agent of the present invention (the above formula) for 1 second, take it out and let it air in the air for 1 minute. Put it in the flame at an angle of 75-80° (t...

Embodiment 2

[0052] Fire extinguishing performance and reflammability.

[0053] The formula used is:

[0054] Potassium bromide: 5%; (mass percentage)

[0055] Tween-80: 0.1%; (mass percentage)

[0056] Sodium carboxymethyl cellulose: 1%; (mass percentage)

[0057] Sodium silicate: 2%; (mass percentage)

[0058] Sodium polyacrylate: 1%; (mass percentage)

[0059] Disodium edetate: 0.2% (mass percentage)

[0060] The balance is water.

[0061] Set a vertical 20cm×50cm×0.5cm pine plank, use a nozzle with the same specification DV95=1000μm, and use 0.8MPa air as the driving pressure to drive water and fire extinguishing agent respectively. Orient the nozzle to the center of the board.

[0062] Set a gasoline ignition source of the same specification under the plank. The specifications of the gasoline oil pan are 8cm×8cm×4cm. After 1 minute of ignition, spray water and fire extinguishing agent respectively.

[0063] Water 15s to extinguish the plank fire. After the water is sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com