Walling method and walling device

A technology for building walls and equipment, applied in the field of building walls, can solve the problems of inability to fully control the flatness and verticality of walls, high labor intensity, low construction efficiency, etc. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

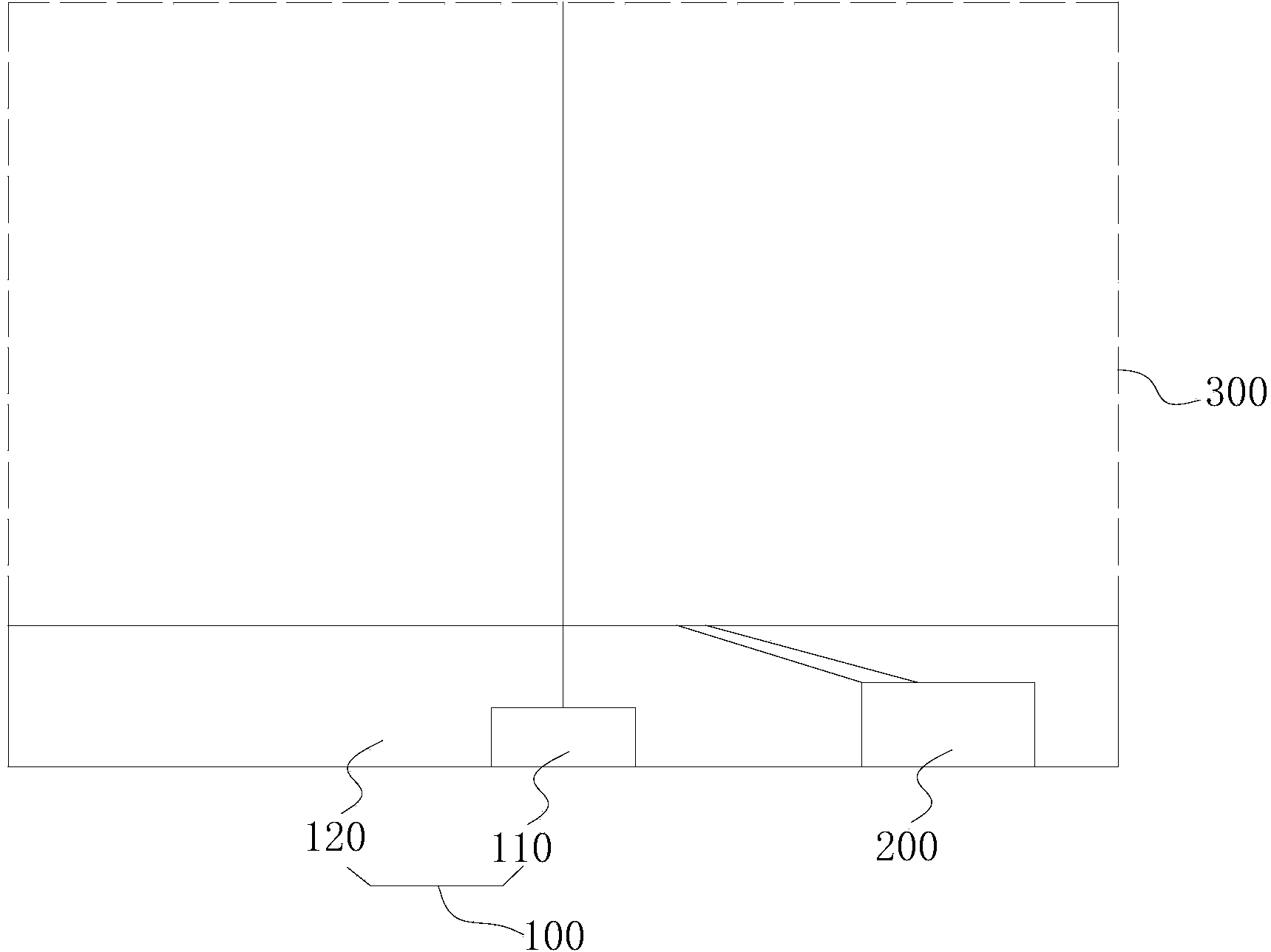

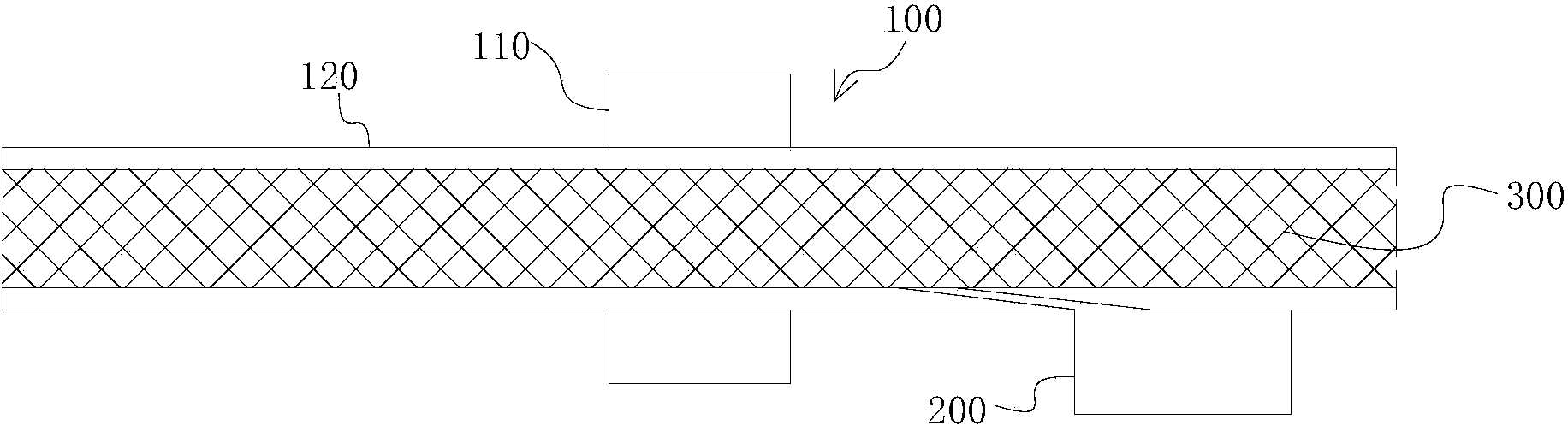

[0053] see Figure 1 ~ Figure 2 , this embodiment discloses a wall-building device, which includes a formwork unit 100 and a pouring unit 200 .

[0054] The template unit 100 includes a driving mechanism 110 and two templates 120 arranged oppositely, wherein: the gap between the two templates 120 is used for pouring slurry wall materials, and the height of the template 120 is smaller than the height of the wall body 300 to be poured. Generally, it is set at a height of 20-50 cm, so as to prevent excessive pressure of one-time poured slurry wall material from causing mold run and slurry leakage. The wall body 300 to be poured is as follows: figure 1 Shown in the dotted line; the width of the template 120 is equal to the width of the wall 300 to be poured, so as to span the entire wall width, and then realize the purpose of a single template 120 without joints; the driving mechanism 110 is used for periodic or continuous The two formworks 120 are lifted.

[0055] The pouring u...

Embodiment 2

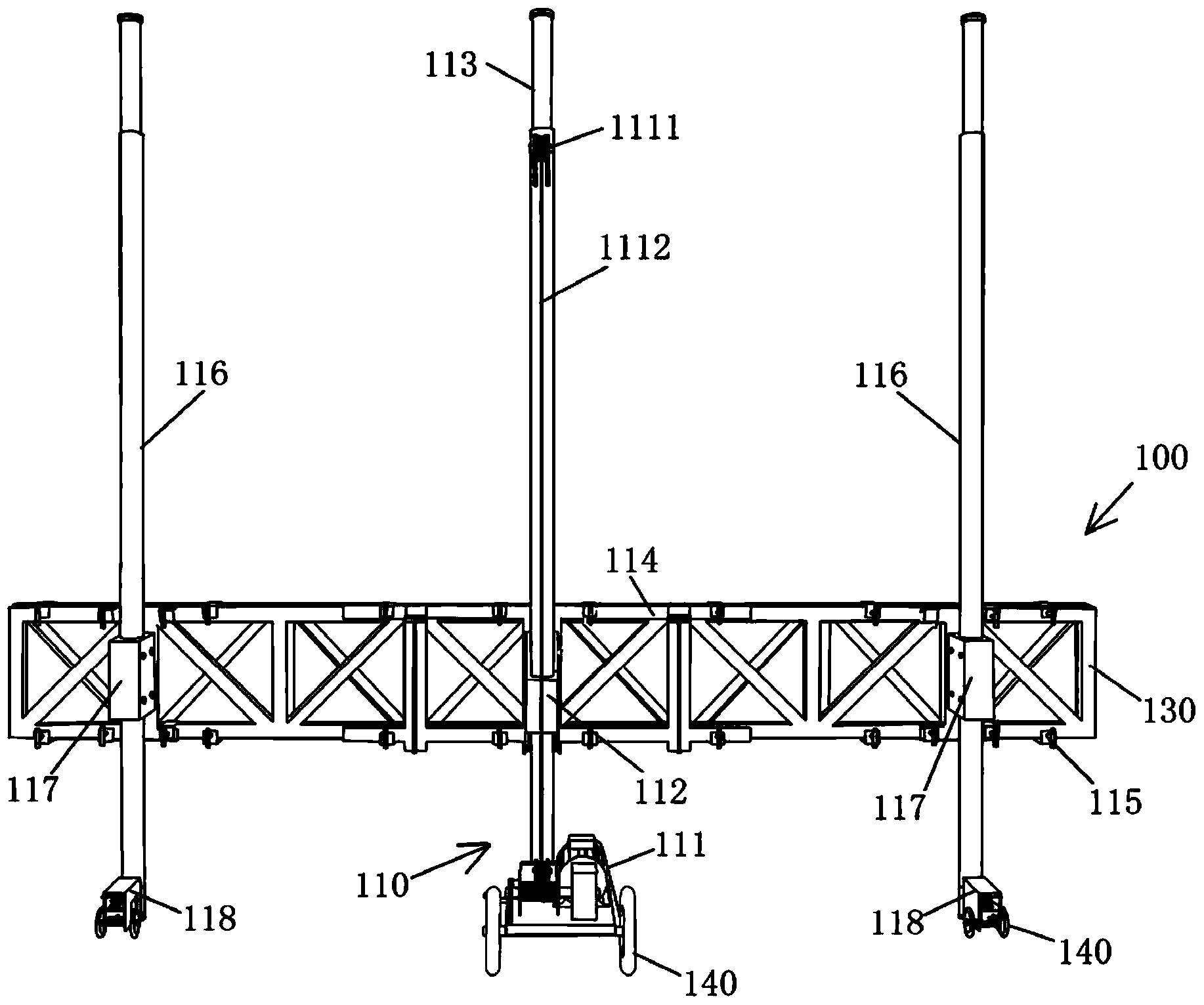

[0058] see Figure 3 ~ Figure 4 , this embodiment also discloses a wall-building equipment, which is a further improvement on the wall-building equipment based on the first embodiment, and the technical solution disclosed in the first embodiment also belongs to this embodiment. Example 1 The disclosed technical solution will not be described again.

[0059] In this embodiment, the template unit 100 is mainly further improved. In order to express the improved technical features more clearly, image 3 and Figure 4 The pour unit is omitted.

[0060] In the present invention, the driving mechanism 110 can adopt various mechanical transmission structures, as long as the template 120 can be lifted. In order to simplify the structure and improve the compactness of the driving structure, in this embodiment, the The driving mechanism 110 is preferably configured to include a hoist 111 , a main slider 112 , a main support column 113 , a lifting claw 114 and a support 130 . Wherein:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com