Improved concrete wall and column construction method

A construction method and technology for concrete walls, applied in the direction of walls, columns, pier columns, etc., can solve the problems of general appearance of concrete roots, increased repair costs, and slow construction progress, so as to achieve small workload, fast construction progress, and avoid The effect of rotten root leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

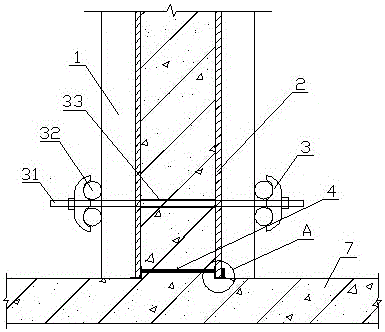

[0021] Such as figure 1 and figure 2 As shown, an improved concrete wall and column construction method includes the following steps:

[0022] (1) Pre-cleaning: Clean up the positions of the walls or columns to be constructed on the surface of the concrete floor 7;

[0023] (2) Binding the foundation reinforcement: binding the foundation reinforcement of the wall or column;

[0024] (3) Welding positioning reinforcement 4: Weld multiple positioning reinforcements 4 side by side at a position where the foundation reinforcement is 15-22mm away from the concrete floor 7. The length of the positioning reinforcement 4 is smaller than the width of the wall or column, and the center of two adjacent positioning reinforcements 4 is ensured. The spacing is 480-520mm;

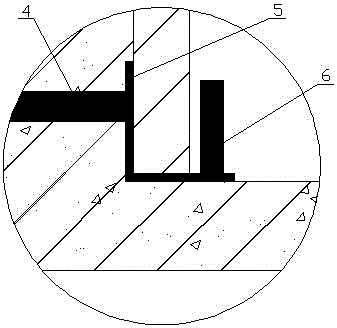

[0025] (4) Install the angle steel 5: install the angle steel 5 on both sides of the foundation steel bar, the inner sides of the vertical sides of the angle steel 5 are respectively against the two ends of the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com