A self-stabilizing wear-resistant testing machine for trolley case

A wear-resistant test and trolley case technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., to achieve accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

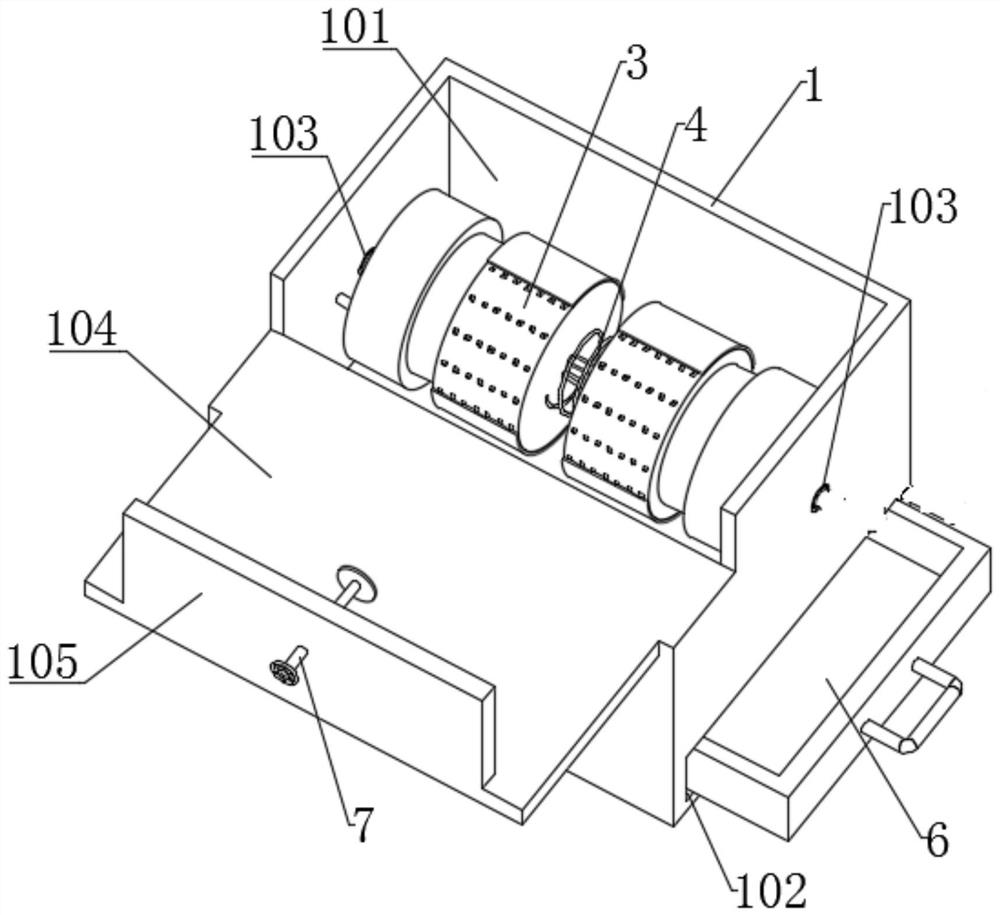

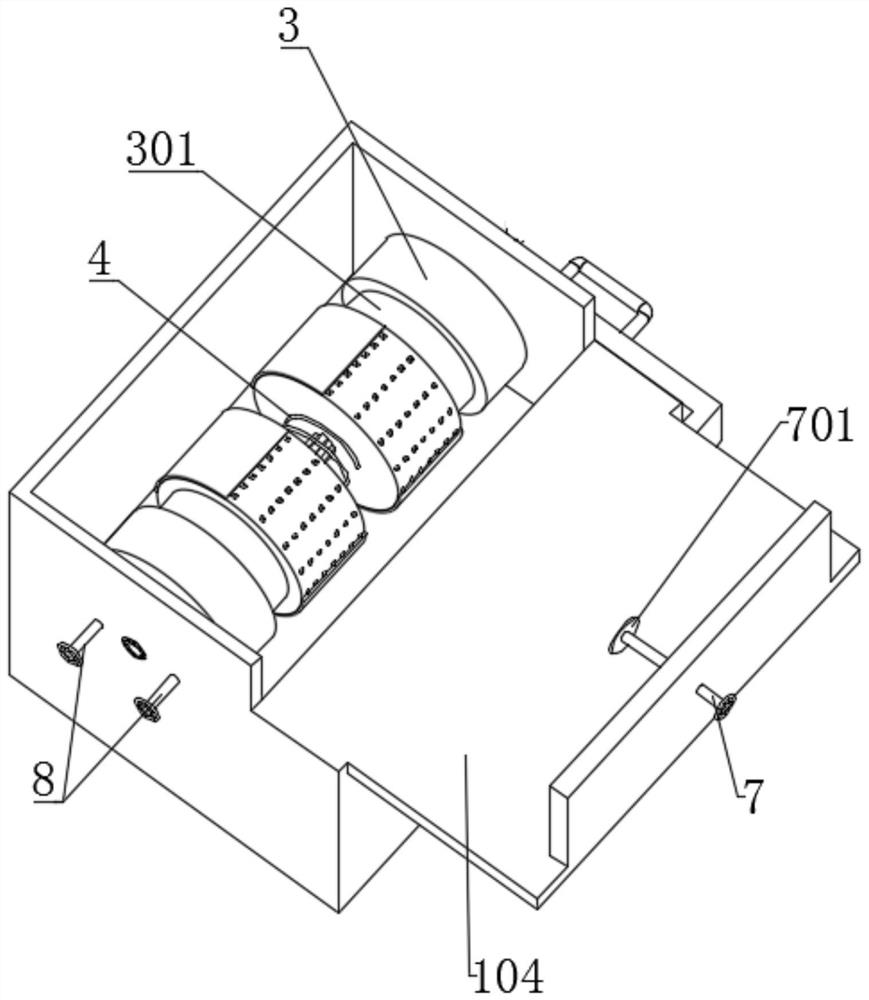

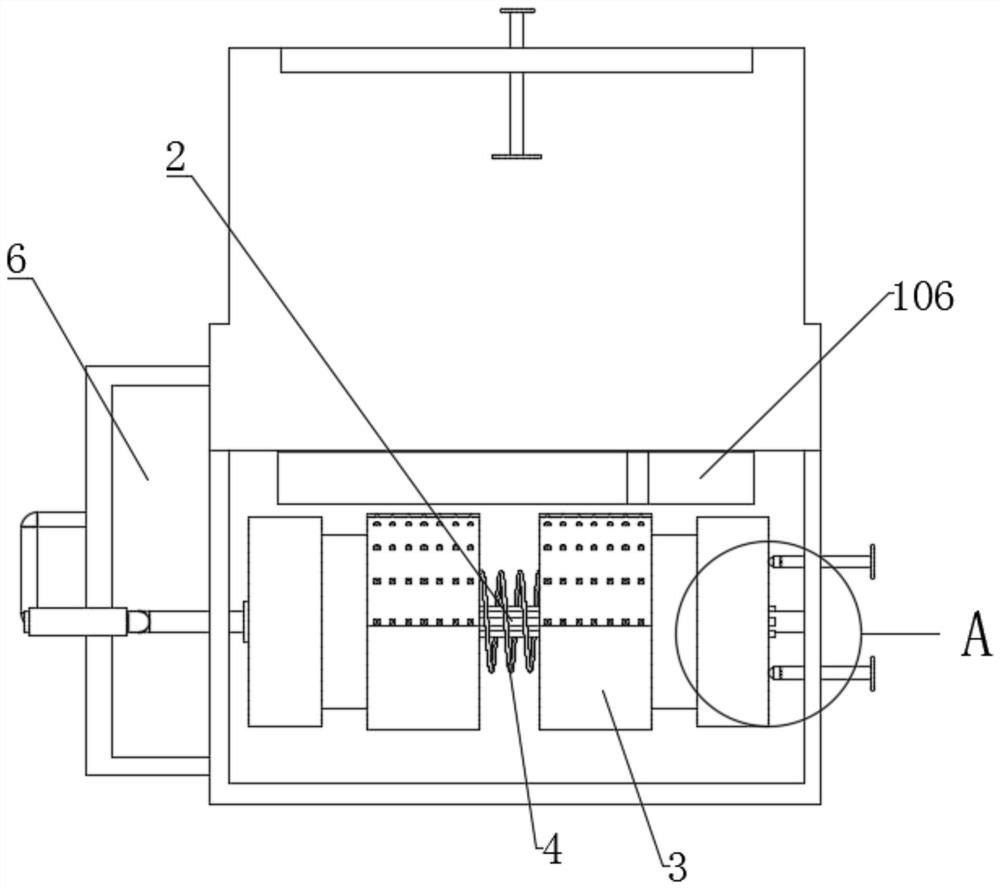

[0037] as attached figure 1 to attach Figure 10 Shown:

[0038] The present invention provides a self-stabilizing trolley case wear-resistant testing machine, which includes a device main body 1, a test chamber 101, an ash drawer chamber 102, a bearing 103, a test platform 104, a vertical plate 105, a dust leak hole 106, a driving motor, and a rotating shaft 2 , limit block 201, rotating bar 202, test roller 3, annular groove 301, rotating hole 302, first test block group 303, arc-shaped rough rubber plate 304, second test block group 305, spring 4, gray Drawer 6, hydraulic ejector rod 7, circular rubber plate 701, adjusting screw 8, universal ball seat 801 and threaded connection column 802; the rear end of the device main body 1 is provided with a test chamber 101, and the rotating shaft 2 passes through the test chamber 101 The bearing 103 at one end is embedded in the bearing 103 on the other end surface of the test cavity 101 , the driving motor is installed on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com