Method for restoring slurry pump casing used for river and sea dredger

A repair method and mud pump technology, applied in the repair field, can solve problems such as equipment waste and increase production costs, and achieve the effects of saving equipment costs, solving maintenance problems, and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

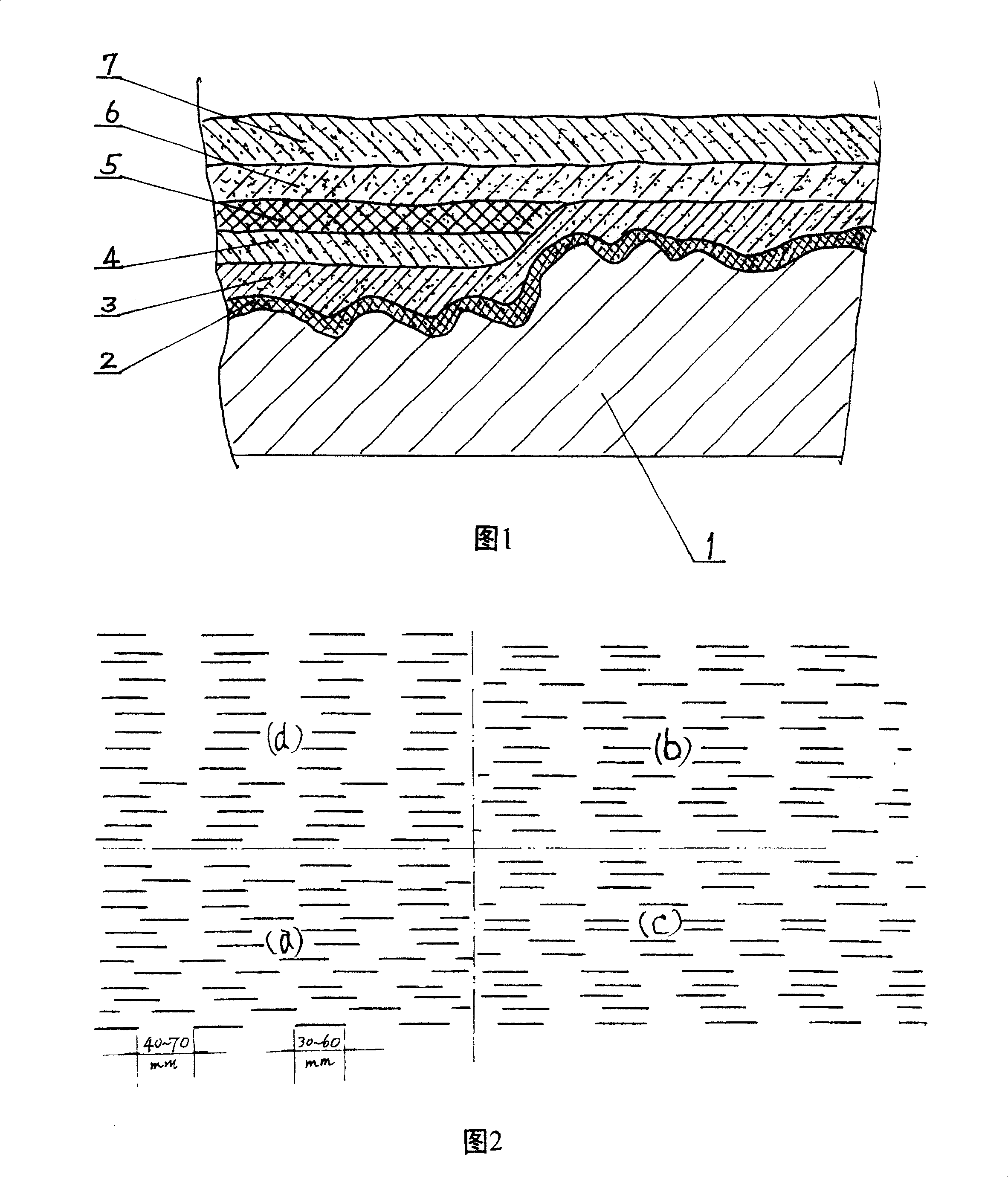

[0020] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] The method for repairing a mud pump casing of a river and sea dredger according to the present invention is divided into: a grinding process, a priming process and a wear-resistant layer surfacing process.

[0022] ① Grinding process: Use sand blasting equipment to remove the rust and burrs on the inner surface of the inner pump casing base 1 of the cleaned mud pump, and grind the uneven groove edges on the inner surface of the base 1 at an angle of 20-30°. Grinding can use tools such as hand grinding wheels, and use compressed air to remove grinding residues and powder particles to ensure that the inner layer is clean.

[0023] ②Priming process: as shown in Figure 1, on the inner surface of the base 1 of the inner pump casing of the clean mud pump, use a DC welding machine, a domestic 68-3 electrode and a UTP83FN special ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com