Circulating drilling-free blind plate cementing device

A circulating and cementing technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., and can solve problems such as downhole accidents, poor sealing of open hole packers, and shortened production life of oil wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

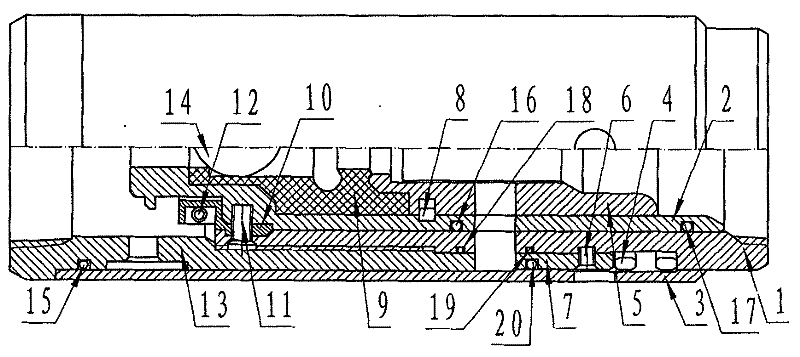

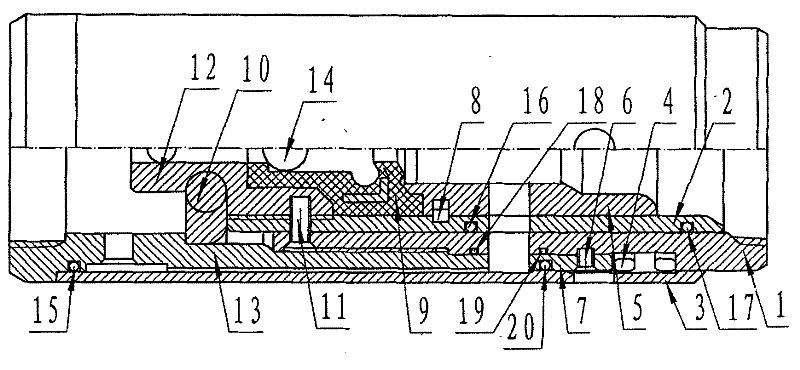

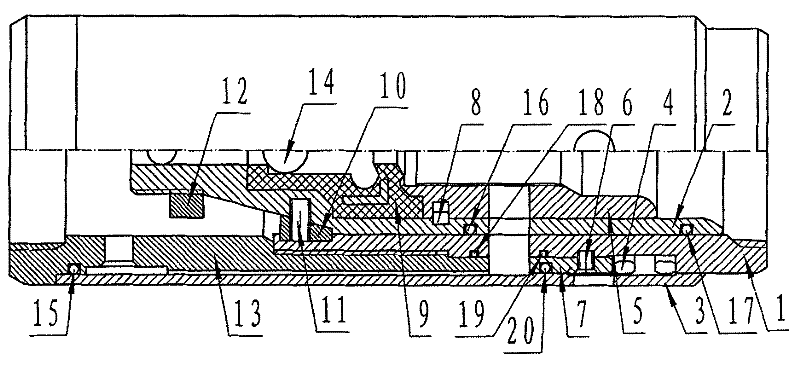

[0016] The present invention will be further explained according to the accompanying drawings: the circulation type no-drilling blind cementing device is composed of a diverter sub, a circulation sub and a sealing rubber ring: a circulation sub 2 is installed in the diversion sub 1 and fixed The bracket 11 and the fixed shear nail 12 are fixed to each other and sealed with a sealing rubber ring 15, and a locking spring 13 is bound on the fixed bracket 11 to tighten the fixed bracket 11; a seat seal rubber tube 9 is installed in the circulation nipple 2 and the salvage sub-joint 5 are fixed; wherein: the snap ring 8 fixes the salvage sub-joint 5, and the salvage sub-joint 5 presses and fixes the outer string of the seat seal rubber cylinder 9 at the same time; The seal 10 can enter the seat seal rubber cylinder 9 to block the circulation channel under the action of pressure; the shunt nipple 1 is equipped with a sealing shield 3 and the sealing shield 3 is equipped with a closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com