Real-time early warning method for casing abrasion risk

A casing and risk technology, applied in the field of real-time early warning of casing wear risk, can solve problems such as casing strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings.

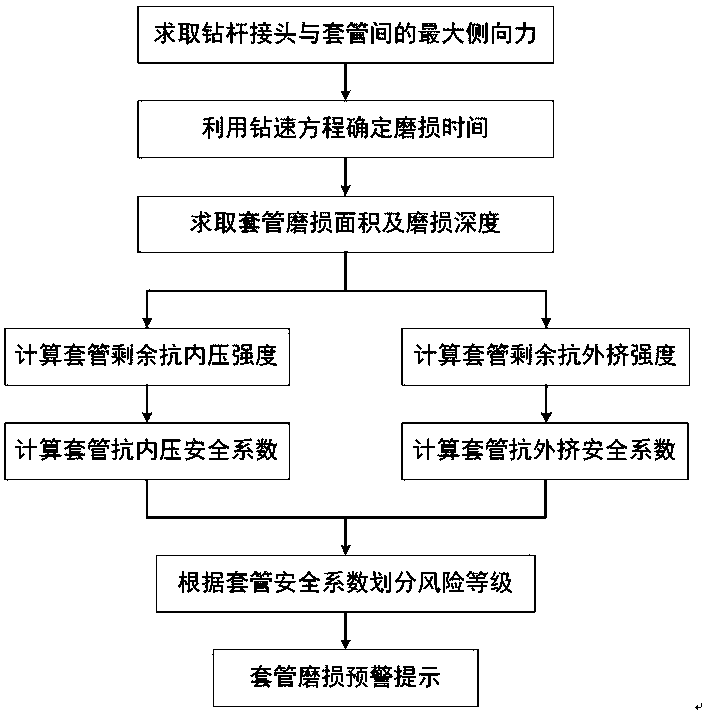

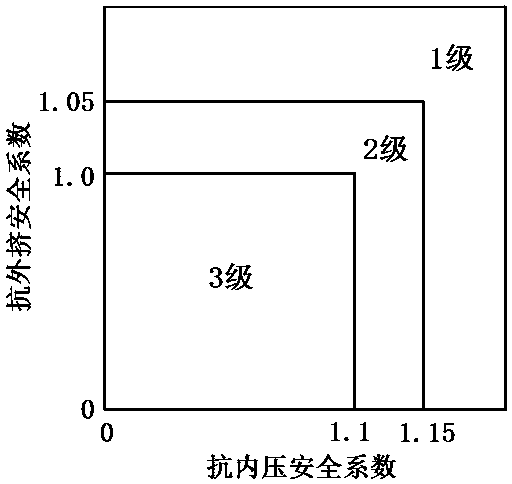

[0066] Depend on figure 1 and figure 2 Shown: a real-time early warning method for casing wear risk, characterized in that, firstly, the maximum lateral force between the drill pipe joint and the casing is selected by calculation, and the wear time is determined by using the penetration rate equation to obtain the casing wear area and depth; then calculate the remaining internal pressure resistance and residual crushing strength of the casing, and calculate the remaining internal pressure safety factor and the remaining crushing safety factor of the casing. The risk level is divided by the extrusion safety factor; finally, the casing wear condition is determined according to the risk level and a real-time early warning is given; the specific steps are as follows:

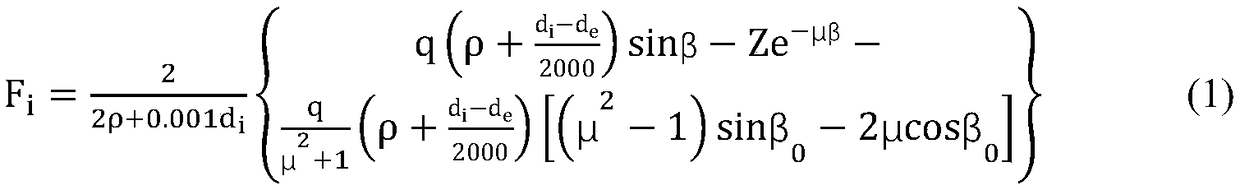

[0067] Step 1: Calculate the lateral force between the drill pipe joint and the casing in sections a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com