A device for measuring wear of drill pipe connection section and casing

A drill pipe and casing technology, applied in the field of friction and wear measurement devices, can solve problems such as casing easy to rotate, point contact, collision, etc., and achieve the effect of avoiding multiple wear and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

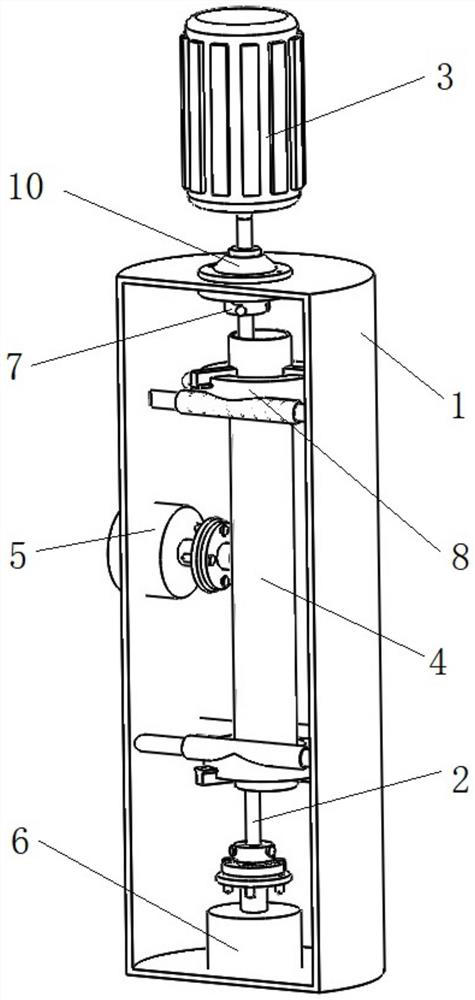

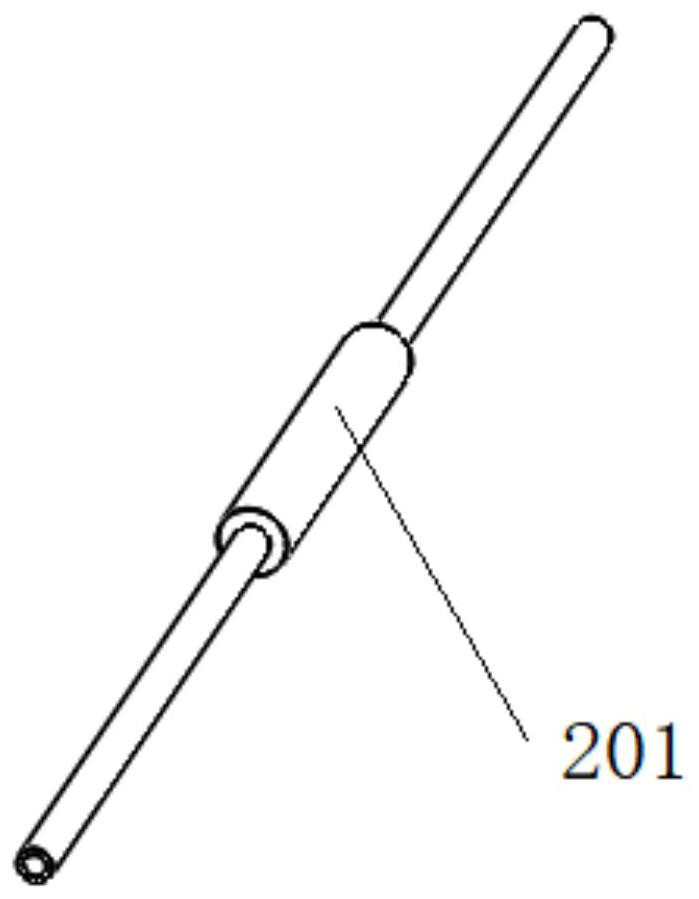

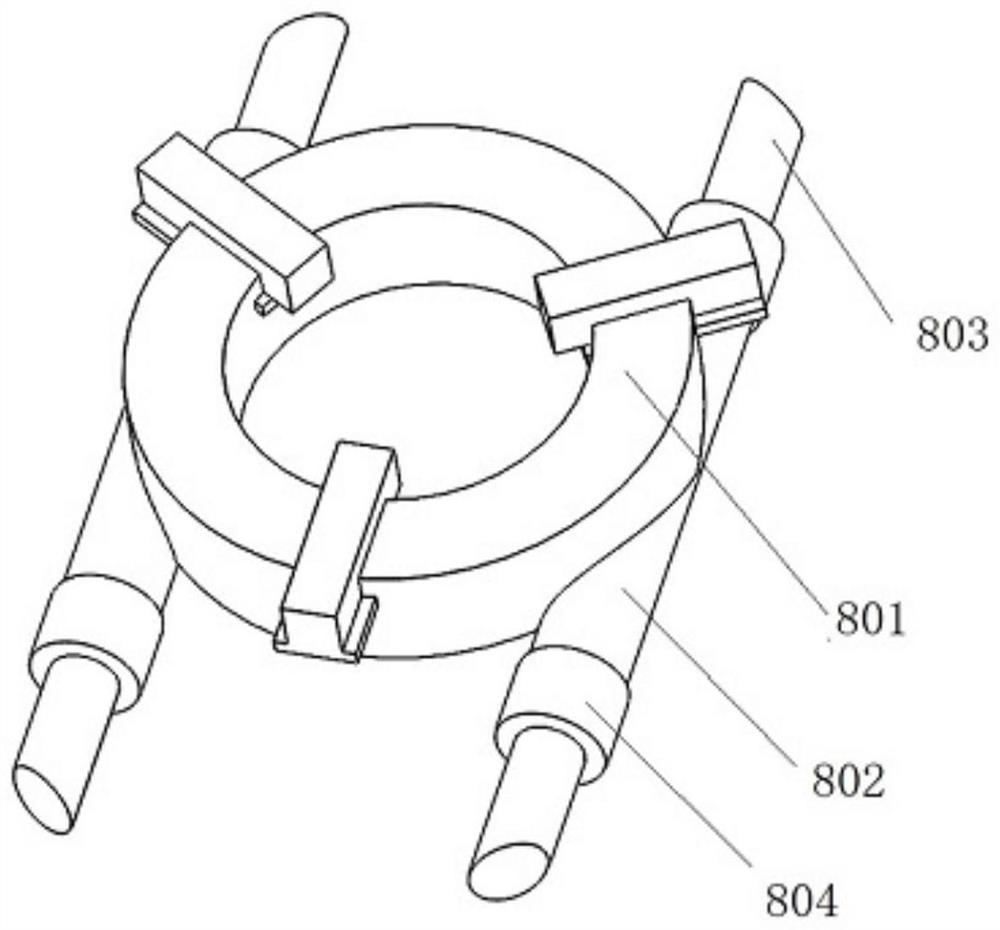

[0025] Please refer to figure 1 , figure 1 It is a sectional view of the overall structure of the present invention. A device for measuring the wear of drill pipe and casing, comprising a liquid storage tank 1, a drill pipe 2, a rotary motor 3, a sleeve 4, a horizontal force application mechanism 5 and an axial force application mechanism 6; the liquid storage tank 1 is used to carry The various components of the device and the storage drilling fluid; the rotary motor 3 is located outside the liquid storage tank 1, and is used to drive the drill pipe 2 to rotate; the drill pipe 2 is located in the liquid storage tank 1, and both ends extend out of the sleeve 4 and pass through the rotating parts. 7 is fixed in the liquid storage tank 1, specifically, the rotating part 7 located at the top of the drill pipe 2 is fixedly connected with the top of the liquid storage tank 1, and the rotating part 7 located at the bottom of the drill pipe 2 and the telescopic end of the axial forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com