Method for preventing casing wear in oil field

A casing and oil field technology, applied in the field of oil and natural gas exploitation, can solve the problems of rock mass displacement, casing damage, preventive measures to treat the symptoms but not the root cause, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the present invention, several aspects are described below.

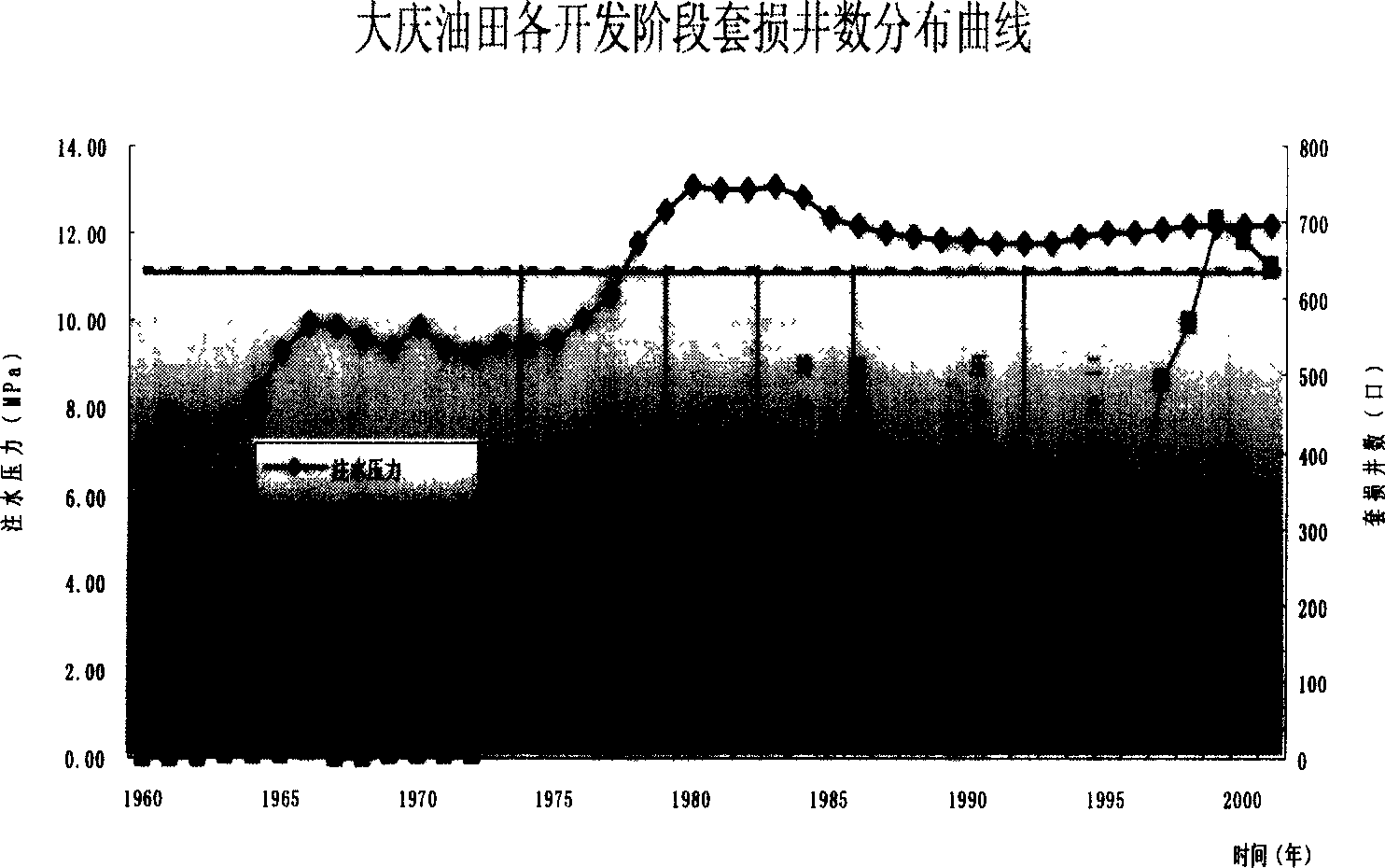

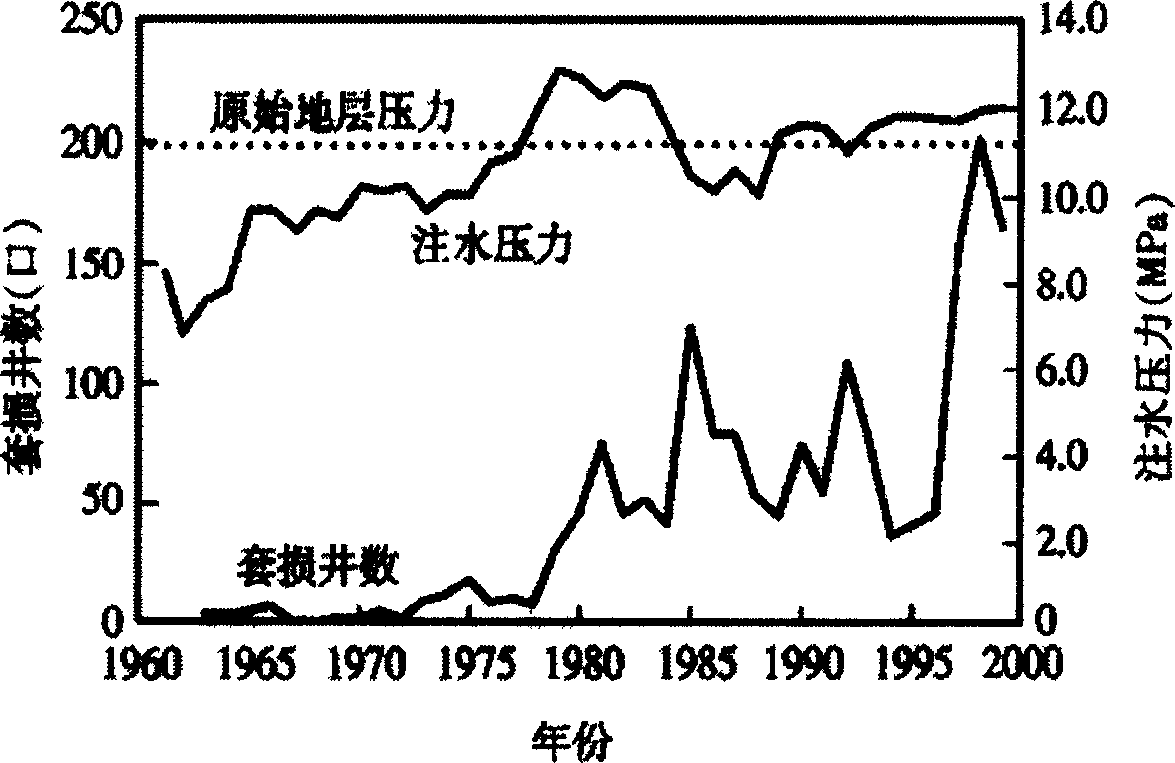

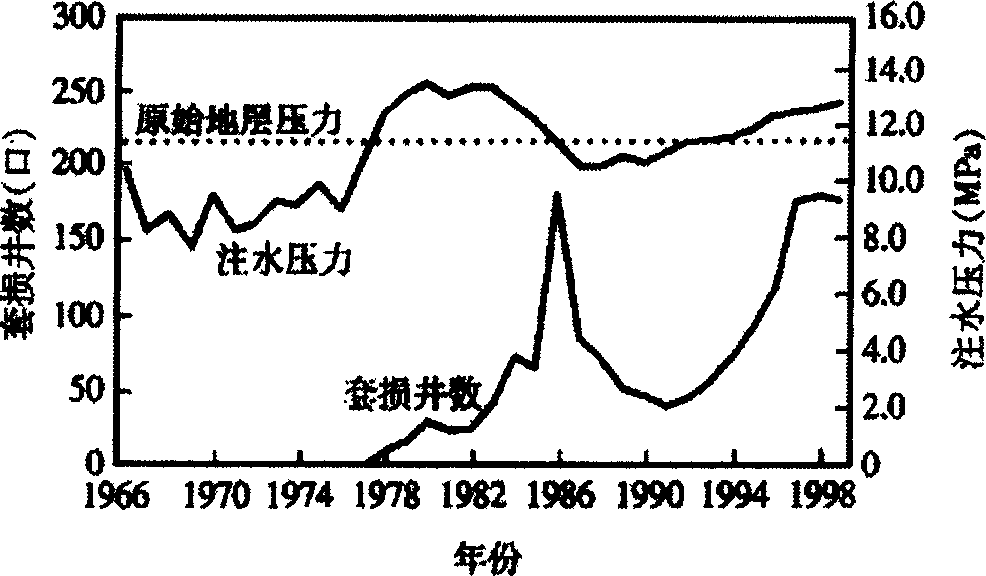

[0030] (1) Mechanical principles of casing damage and rock mechanical properties

[0031] 1. Mechanical principle of casing damage

[0032] As far as the casing damage is concerned, the steel grade strength of the casing itself, the consolidation strength between the casing and the rock formation, and the rock mechanical properties of the rock formation itself are the internal factors leading to casing damage, which are solid mechanics problems; and the pores caused by water injection, etc. The change of water pressure is an external factor leading to casing damage, which belongs to the problem of fluid mechanics. The Mohr-Coulomb law realizes the unity of the two, and constitutes the theoretical basis for the analysis of porous rock deformation mechanics.

[0033] As we all know, the response of an object to an external load depends on the size of the load, the shape of the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com