Novel high-temperature magnetic drive pump

A magnetic pump, high temperature technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of pumps not working normally, complex structure, damage, etc., and achieve the effect of avoiding excessive shaft temperature, increasing contact area, and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

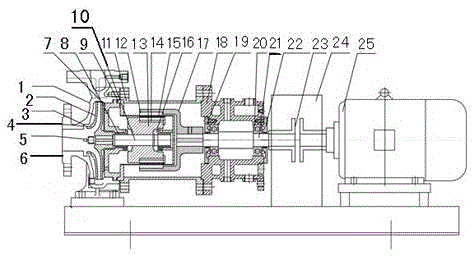

[0015] Embodiment 1, with reference to figure 1 , is a new type of high-temperature magnetic pump, including a motor 25, a pump body 1, a pump cover 7, an impeller 2, a bearing housing 18 and a pump inlet 6 arranged at the front end of the pump body 1, and is characterized in that the output shaft of the motor 25 The end is connected with the drive shaft 21 through a coupling 23, the coupling 23 is covered with a coupling cover 24, the pump body 1 is provided with a pump body mouth ring 3, and the impeller 2 is set on the impeller. The bottom of the wheel shaft 10 is provided with the impeller nut 5 for locking the impeller 2 at the bottom of the impeller shaft 10, the impeller mouth ring 4 is arranged on the impeller 2, and the inner magnetic steel 13 and the outer magnetic steel are fixed on the end of the impeller shaft 10. 17 and spacer sleeve 9, a magnetic sheet 12 is provided between the inner magnetic steel 13 and the outer magnetic steel 17, and a positioning sleeve 14...

Embodiment 2

[0016] Embodiment 2, in the novel high-temperature magnetic pump described in Embodiment 1: several rectangular vanes are arranged outside the bearing housing 18, bearing glands 19 are arranged in the bearing housing 18, and bearing glands 19 are provided with Labyrinth seal and dust disc.

Embodiment 3

[0017] Embodiment 3, in the novel high-temperature magnetic pump described in Embodiment 1: a bearing housing cover plate 22 is provided outside the bearing housing 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com