Noncontact air-floating platform

An air-floating platform, non-contact technology, applied in conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of low conveying efficiency, uneven air film, self-excited vibration of glass substrate, etc., to achieve low energy consumption , The structure is simple, the effect of improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

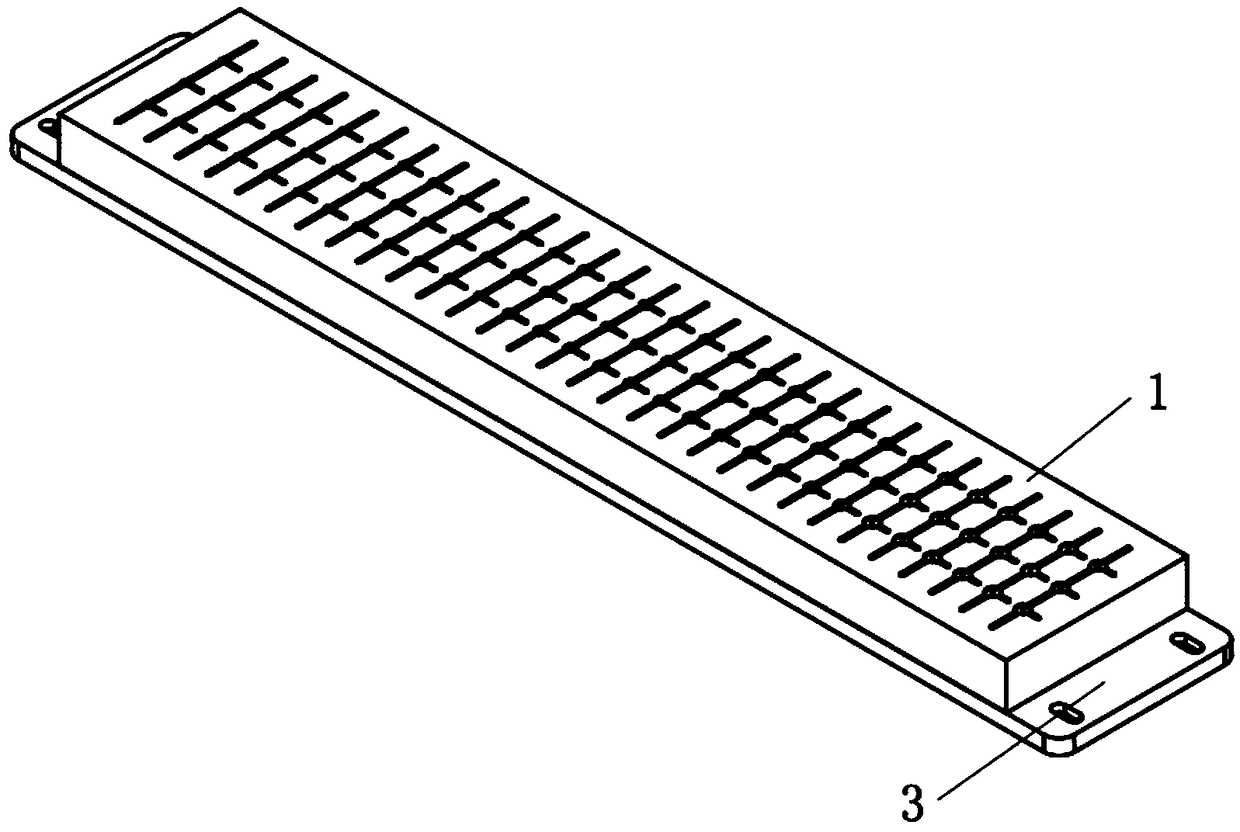

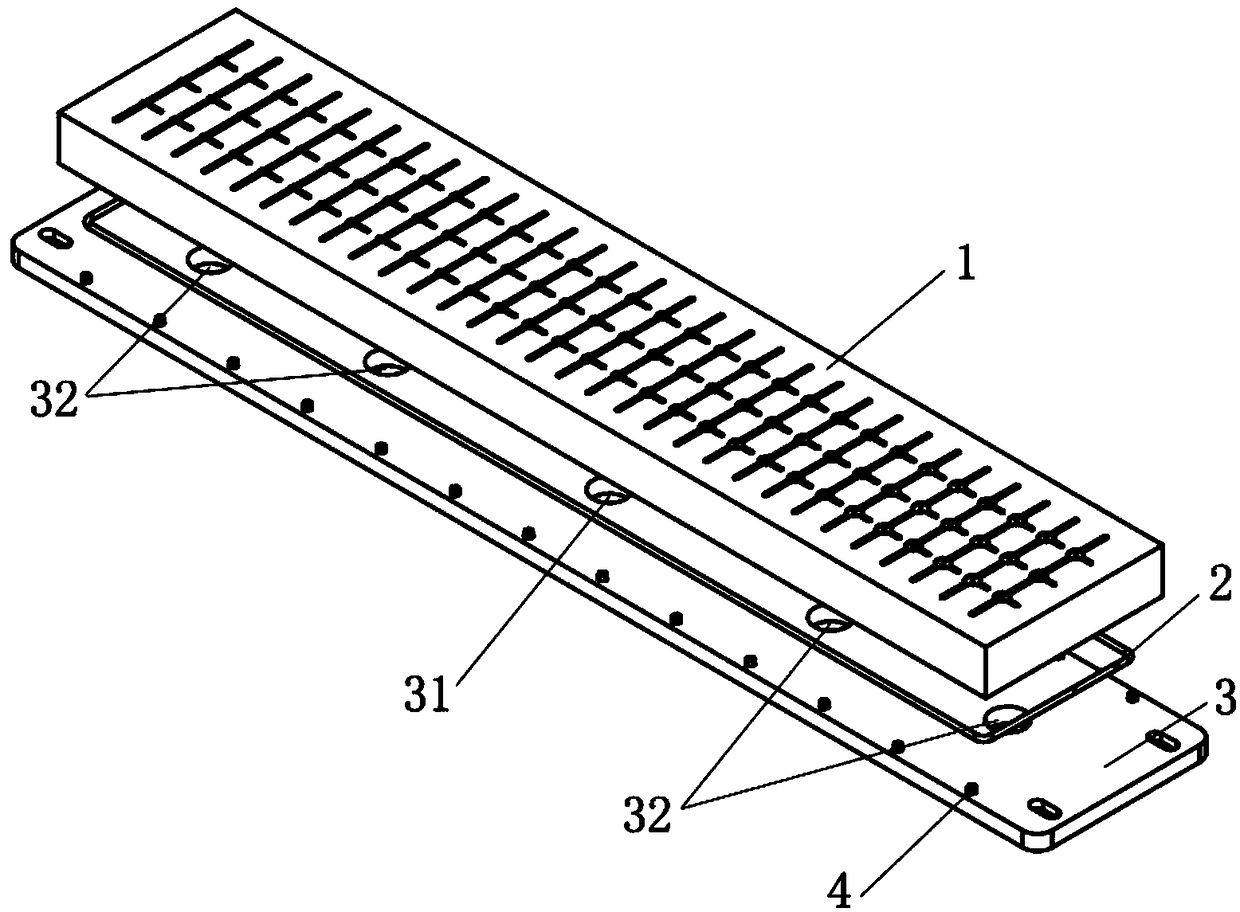

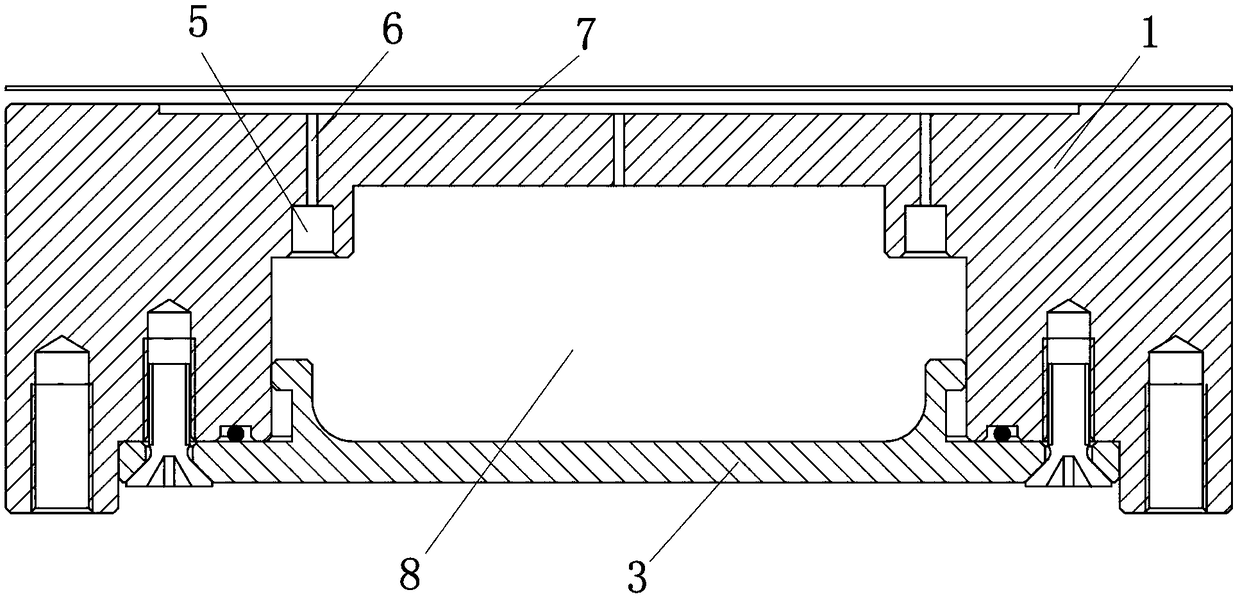

[0026] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following embodiments are combined with figure 1 Attached Figure 4 The non-contact air flotation platform provided by the present invention is described in detail. figure 1 Is a schematic structural diagram of an embodiment of a non-contact air floating platform of the present invention; figure 2 It is an exploded view of an embodiment of a non-contact air floating platform of the present invention; image 3 Is a longitudinal cross-sectional view of an embodiment of a non-contact air floating platform of the present invention; Figure 4 It is a top view of the pressure equalizing groove of the air floatation bar in an embodiment of a non-contact air floatation platform of the present invention. In this embodiment, the non-contact air flotation platform mainly includes air flotation strip 1, sealing ring 2, sealing bottom plate 3, air inlet hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com