Full-automatic cleaning device of spraying tool

A fully automatic cleaning and cleaning technology, applied in the direction of spraying devices, liquid spraying equipment, etc., can solve the problems of unguaranteed product quality, unguaranteed life of spraying tools, low production efficiency, etc., to improve productivity, structure Simple, life-extending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

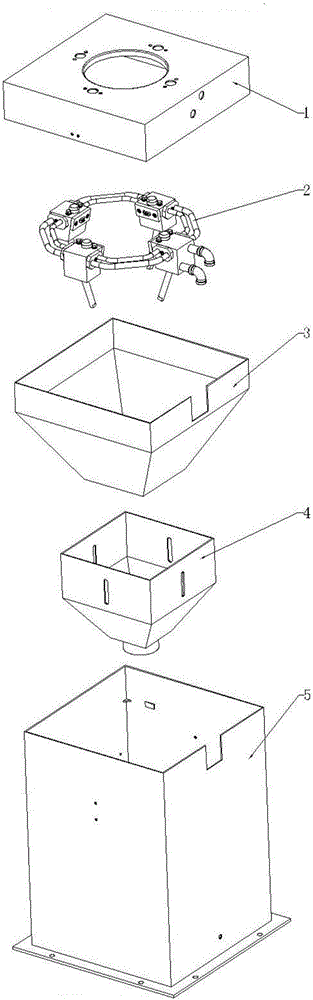

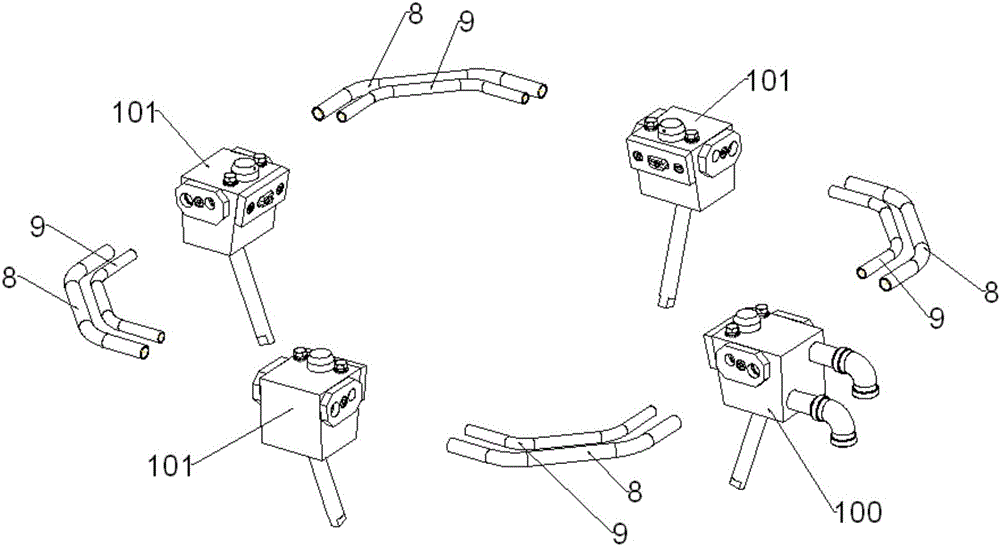

[0029] Such as figure 1 , figure 2 As shown, a spray tool automatic cleaning device, which includes a cover (1), a spray assembly (2), a negative pressure tank (3), a funnel (4), a support seat (5), a total of five parts; the funnel (4) Put it into the supporting seat (5) and fix it with screws; the negative pressure groove (3) is put into the upper part of the supporting seat (5) and is blocked by a stopper; the cover (1) and the injection assembly (2) After being combined by fixing screws (20), put them on the upper part of the support seat (5) to cover; the spray assembly (2) consists of a supply nozzle seat assembly (100) and a total of three nozzle seat assemblies (101). sleeve, and connect each other end-to-end through the air pipe (8) and the solvent fluid pipe (9) to form a spray circuit;

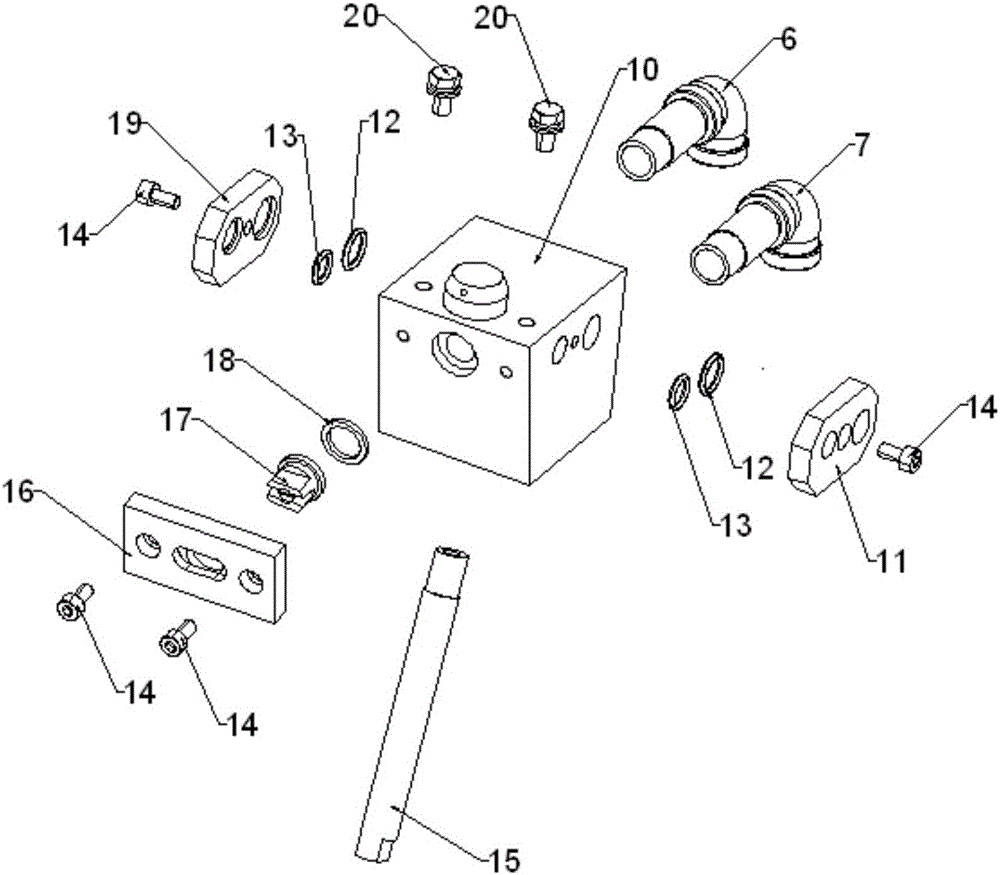

[0030] Such as image 3 As shown, the supply nozzle seat assembly (100) consists of an air inlet pipe joint (6), a solvent feed joint (7), a supply nozzle seat (10), a left baff...

Embodiment 2

[0035] Such as figure 1 , figure 2 As shown, a spray tool automatic cleaning device, which includes a cover (1), a spray assembly (2), a negative pressure tank (3), a funnel (4), a support seat (5), a total of five parts; the funnel (4) Put it into the supporting seat (5) and fix it with screws; the negative pressure groove (3) is put into the upper part of the supporting seat (5) and is blocked by a stopper; the cover (1) and the injection assembly (2) After being combined by fixing screws (20), put them on the upper part of the support seat (5) to cover; the spray assembly (2) consists of a supply nozzle seat assembly (100) and a total of three nozzle seat assemblies (101). sleeve, and connect each other end-to-end through the air pipe (8) and the solvent fluid pipe (9) to form a spray circuit;

[0036] Such as Figure 4 As shown, the nozzle assembly (101) consists of a nozzle seat (21), a left baffle (11), a right baffle (19), a gas pipe sealing ring (12), a solvent pip...

Embodiment 3

[0041] Such as figure 1 , figure 2 As shown, a spray tool automatic cleaning device, which includes a cover (1), a spray assembly (2), a negative pressure tank (3), a funnel (4), a support seat (5), a total of five parts; the funnel (4) Put it into the supporting seat (5) and fix it with screws; the negative pressure groove (3) is put into the upper part of the supporting seat (5) and is blocked by a stopper; the cover (1) and the injection assembly (2) After being combined by fixing screws (20), put them on the upper part of the support seat (5) to cover; the spray assembly (2) consists of a supply nozzle seat assembly (100) and a total of three nozzle seat assemblies (101). sleeve, and connect each other end-to-end through the air pipe (8) and the solvent fluid pipe (9) to form a spray circuit;

[0042] Such as Figure 5 As shown, a spray tool automatic cleaning device, the supply nozzle seat assembly (100) and the nozzle seat assembly (101) are arranged in a ring with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com