High pressure big angle-wrap porous section-variable closed type air-floating ball bearing

A technology with variable cross-section and wrapping angle, which is applied to bearings, shafts, bearings, mechanical equipment, etc., can solve the problems of deterioration of bearing dynamic characteristics, decrease of bearing capacity, low air supply pressure, etc., and achieve the improvement and expansion of sudden pressure drop The scope of application and the effect of increasing the bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

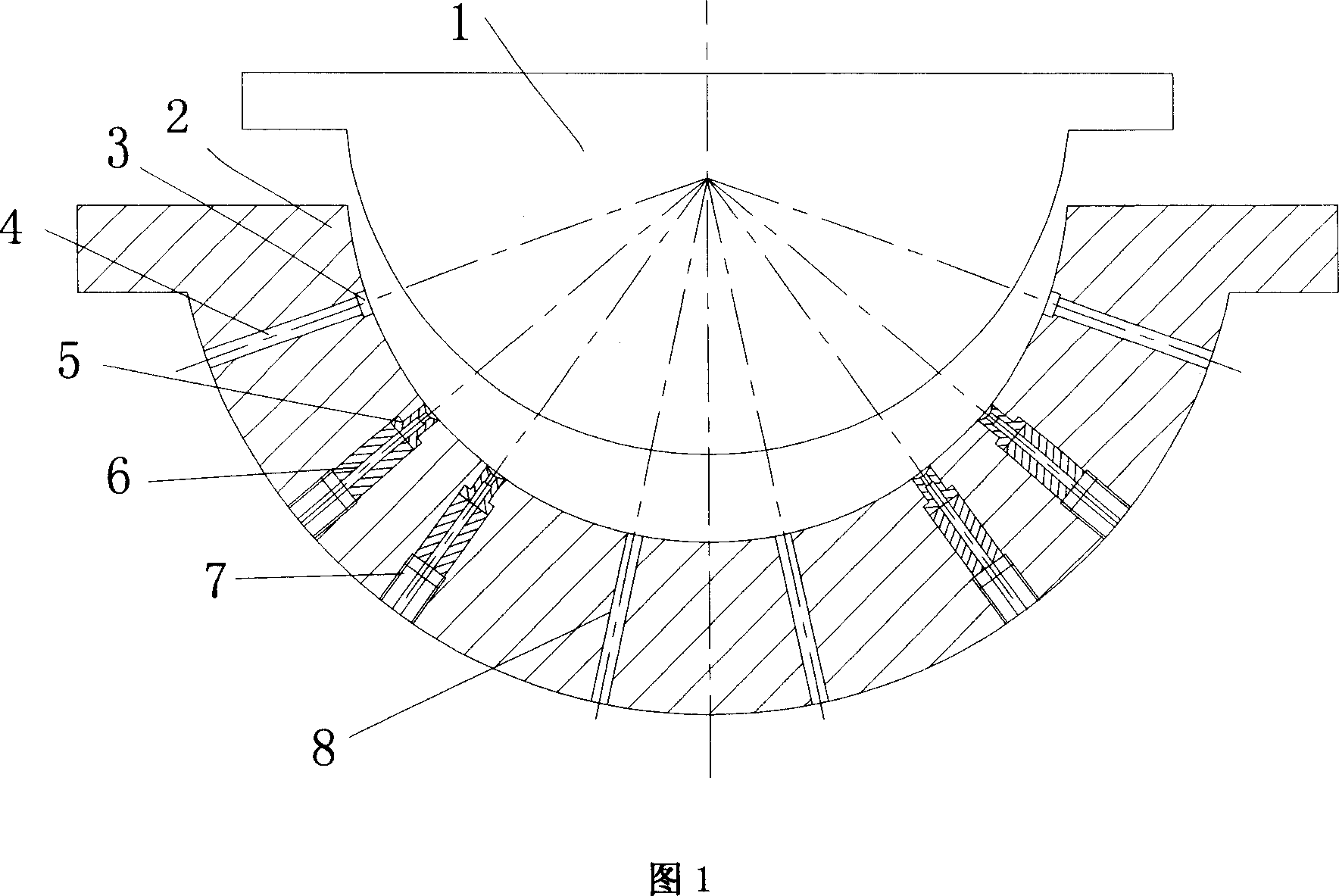

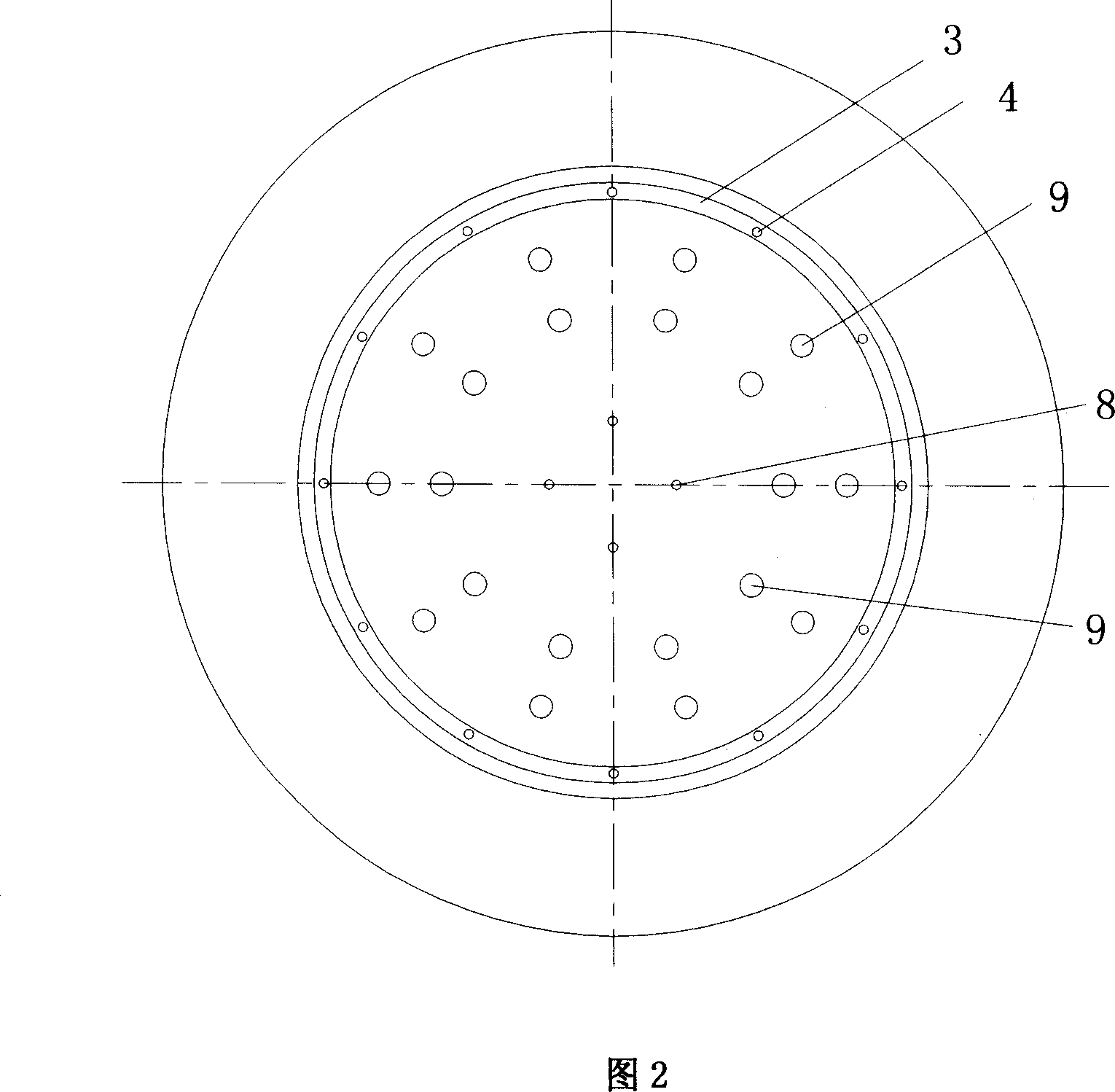

[0013] As shown in Figures 1 to 4, there are single or multiple rows of air supply holes 9 on the ball socket, in which are equipped with air supply plugs 5, positioning sleeves 6, and fixed plugs 7, which provide passages for the working medium to flow through. At the same time, the surface of the ball socket is also processed with an exhaust equalizing groove 3 , an exhaust hole 4 and an exhaust hole 8 .

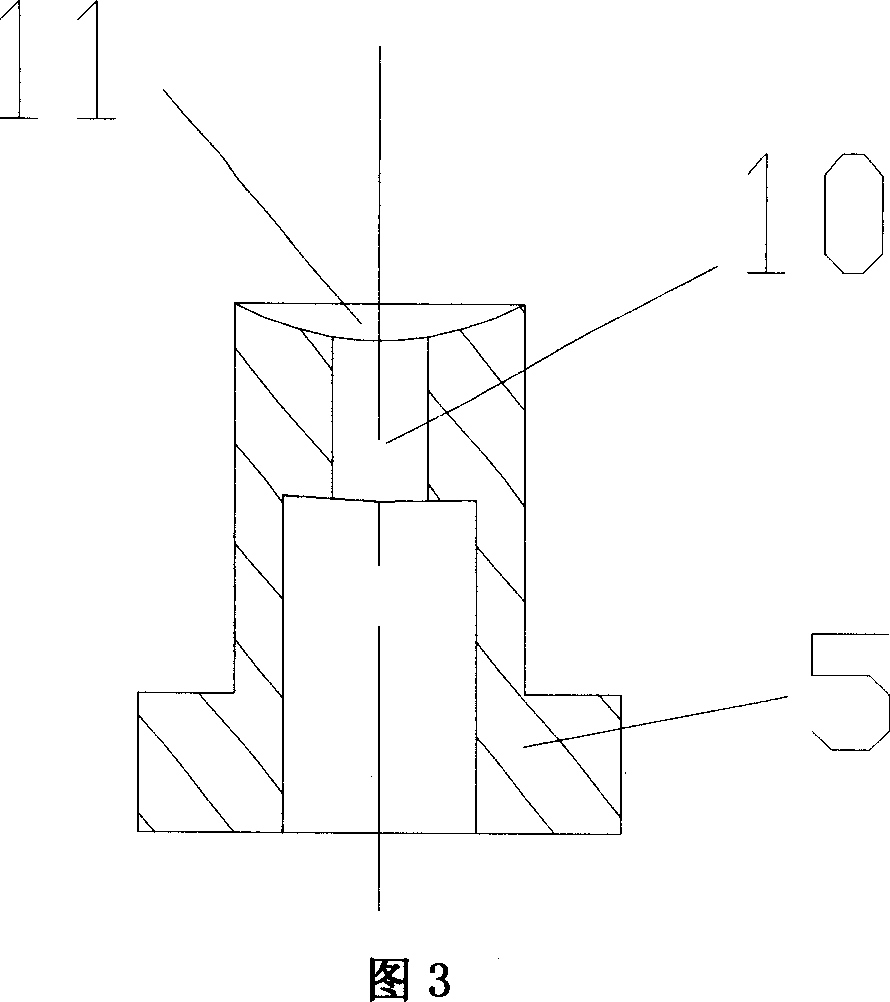

[0014] The gas with a pressure of 0.3-1.5 MPa enters the air film gap of the bearing through the air supply plug 5 assembled in the ball socket inlet passage 9, the positioning sleeve 6 and the fixed plug 7, and provides supporting force to act on the ball head. The external load is balanced. Since the gas supply plug 5 is processed with a curved surface gradually expanding mixing chamber 11 and a conical surface gradually expanding mixing chamber 12, under the working conditions of high pressure and atmospheric film, the setting and optimization of the curved surface grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com