Force feedback device

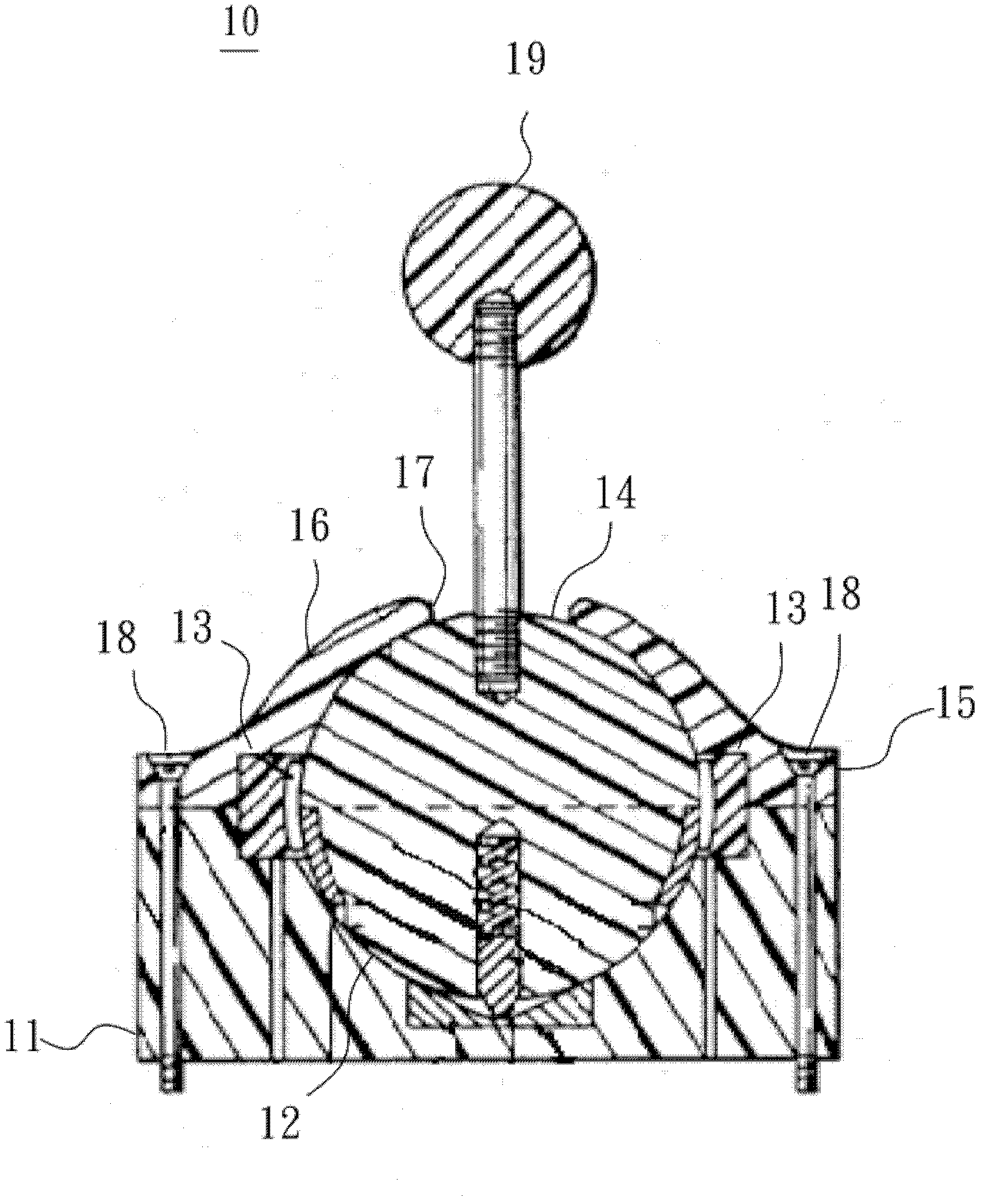

A technology of shafts and slots, applied in mechanical control devices, devices for preventing/restricting/restoring the movement of parts of the control mechanism, and manually operated control mechanisms, can solve the problem of reducing the movement precision of the rocker 19 and affecting the rocker Problems such as the operating feel of the rod 19 and the impossibility of precise positioning of the ball 14

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to achieve the above object, the present invention adopts the technical means and its effects, hereby give preferred embodiments, and illustrate as follows in conjunction with the accompanying drawings.

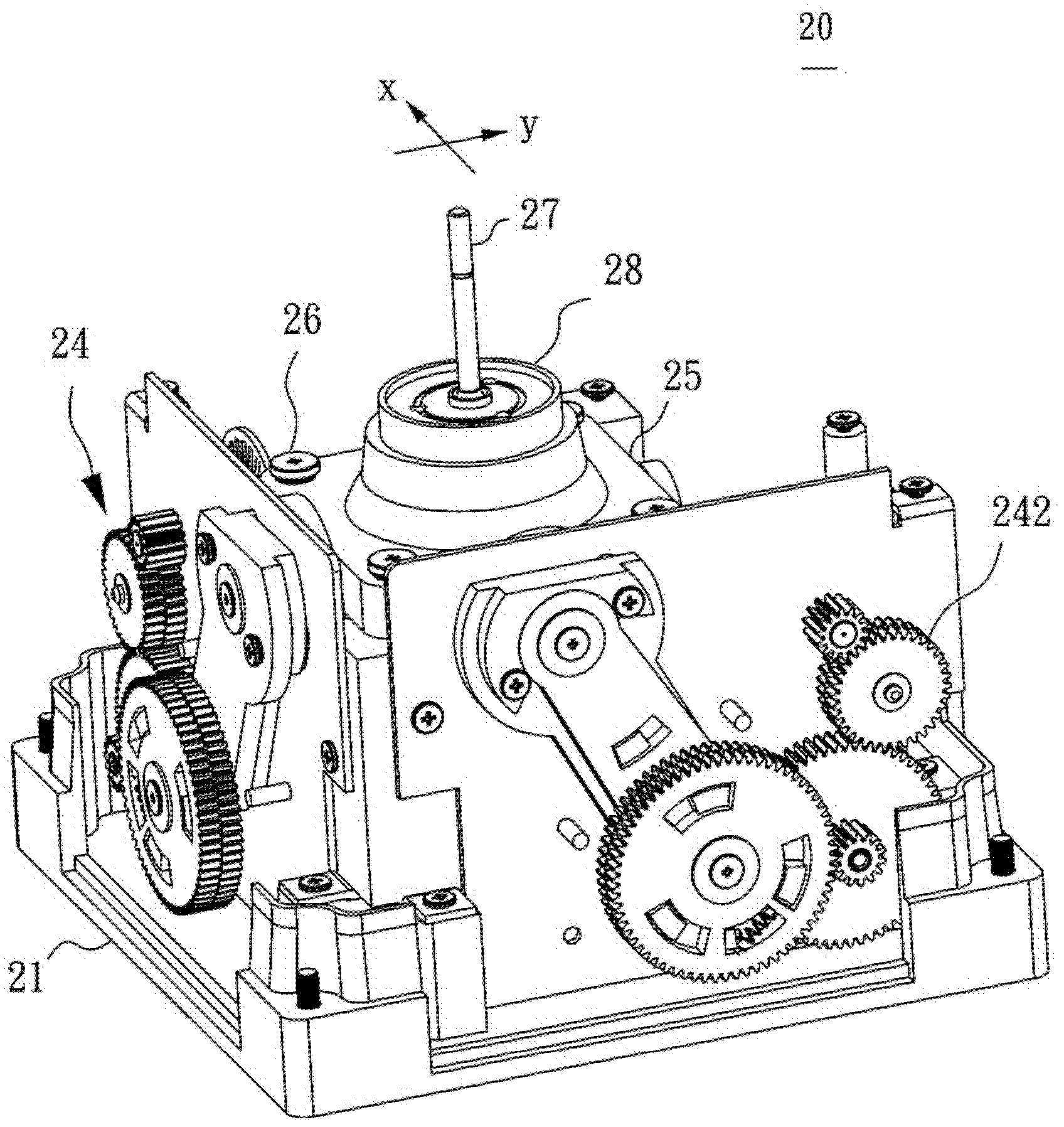

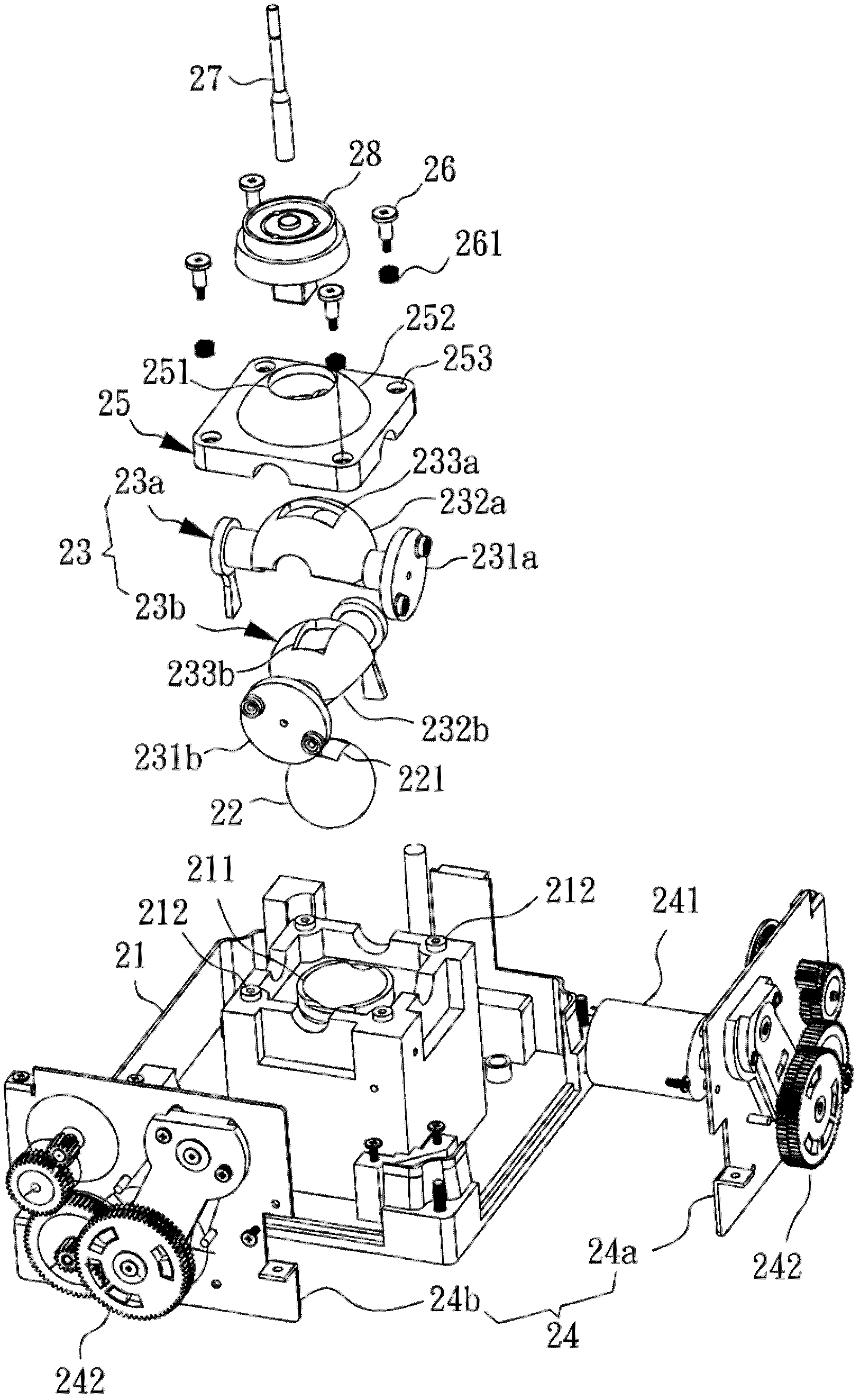

[0042] see figure 2 and image 3 , figure 2 is a perspective view of the force feedback device 20 according to the first embodiment of the present invention, image 3 It is an exploded view of the force feedback device 20 according to the first embodiment of the present invention. The force feedback device 20 of the present invention mainly includes a base 21 , a ball 22 , a shaft unit 23 , a force feedback unit 24 , a top cover 25 , a combined bolt 26 and a rocker 27 . Wherein, a groove 211 is recessed on the base 21 , and several screw holes 212 are respectively arranged around the groove 211 . The ball 22 is arranged to rotate in the groove 211 , and a coupling hole 221 is arranged on the ball 22 .

[0043] The shaft unit 23 includes at least one sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com