Production device and method of blasting bead sanitation product

A sanitary product and production device technology, applied in the fields of application, medical science, clothing, etc., can solve the problems of buttock injury, eliminate odor, and the difficulty of long-term fragrance of physiological products, etc., and achieve the effect of simple overall structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below through specific embodiments.

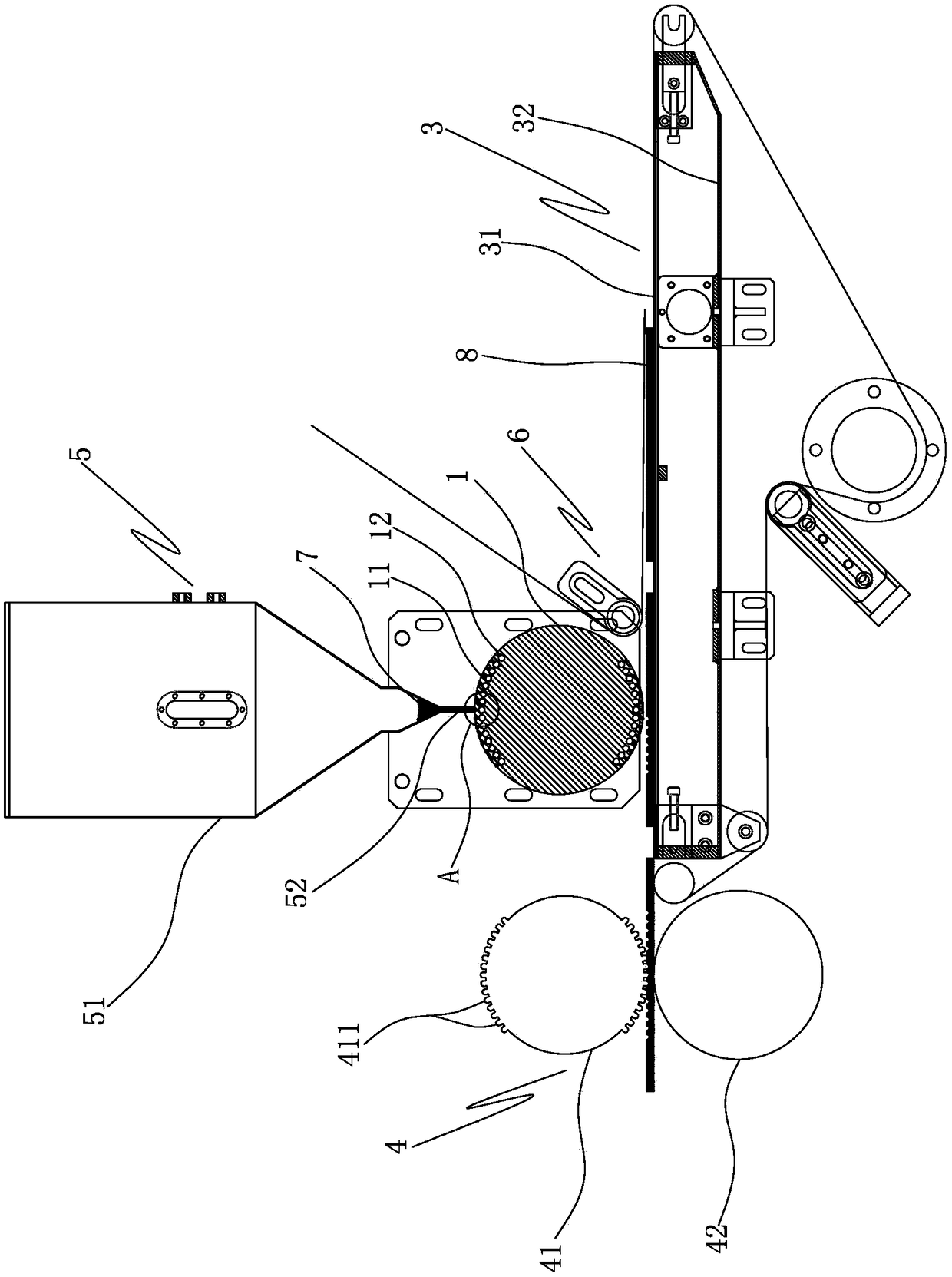

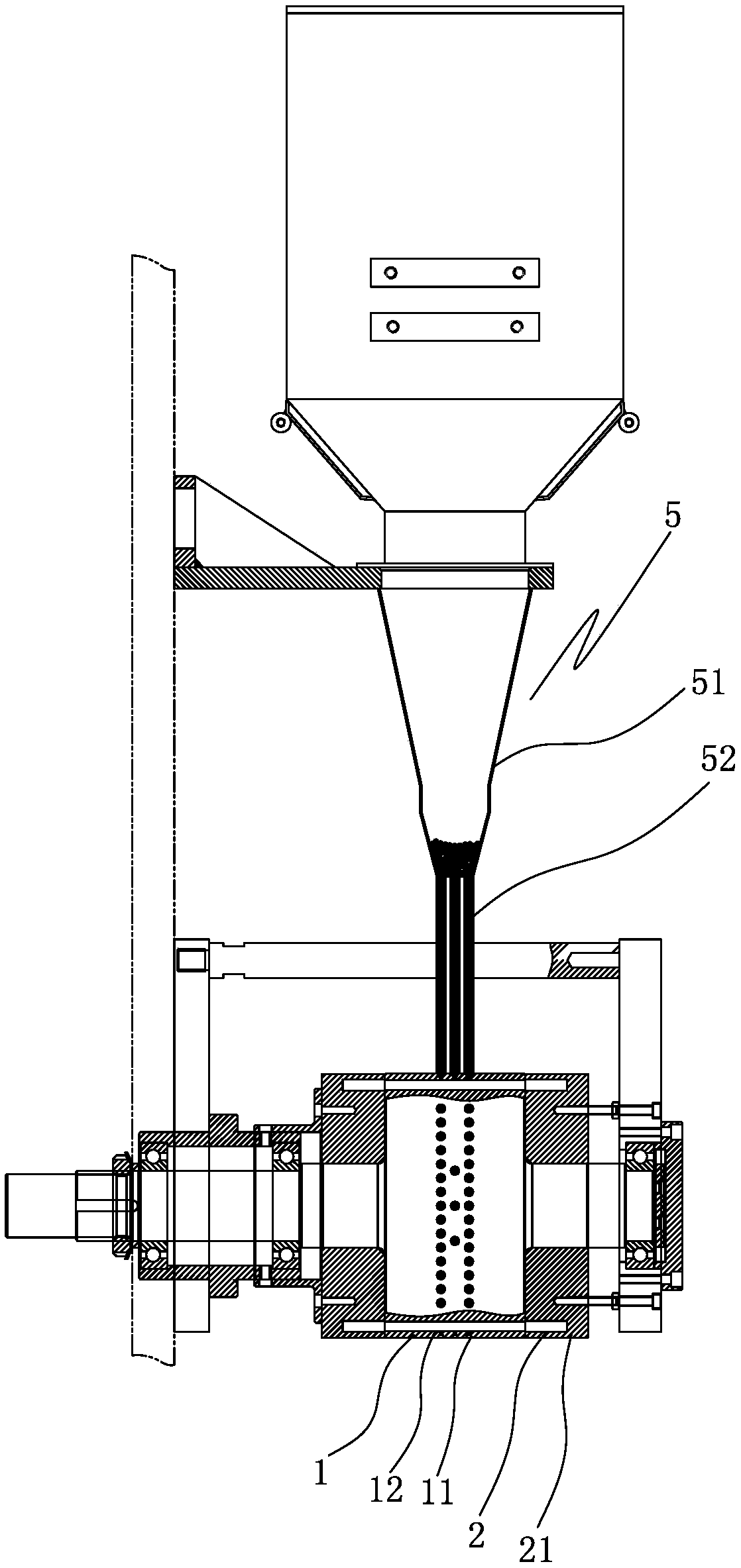

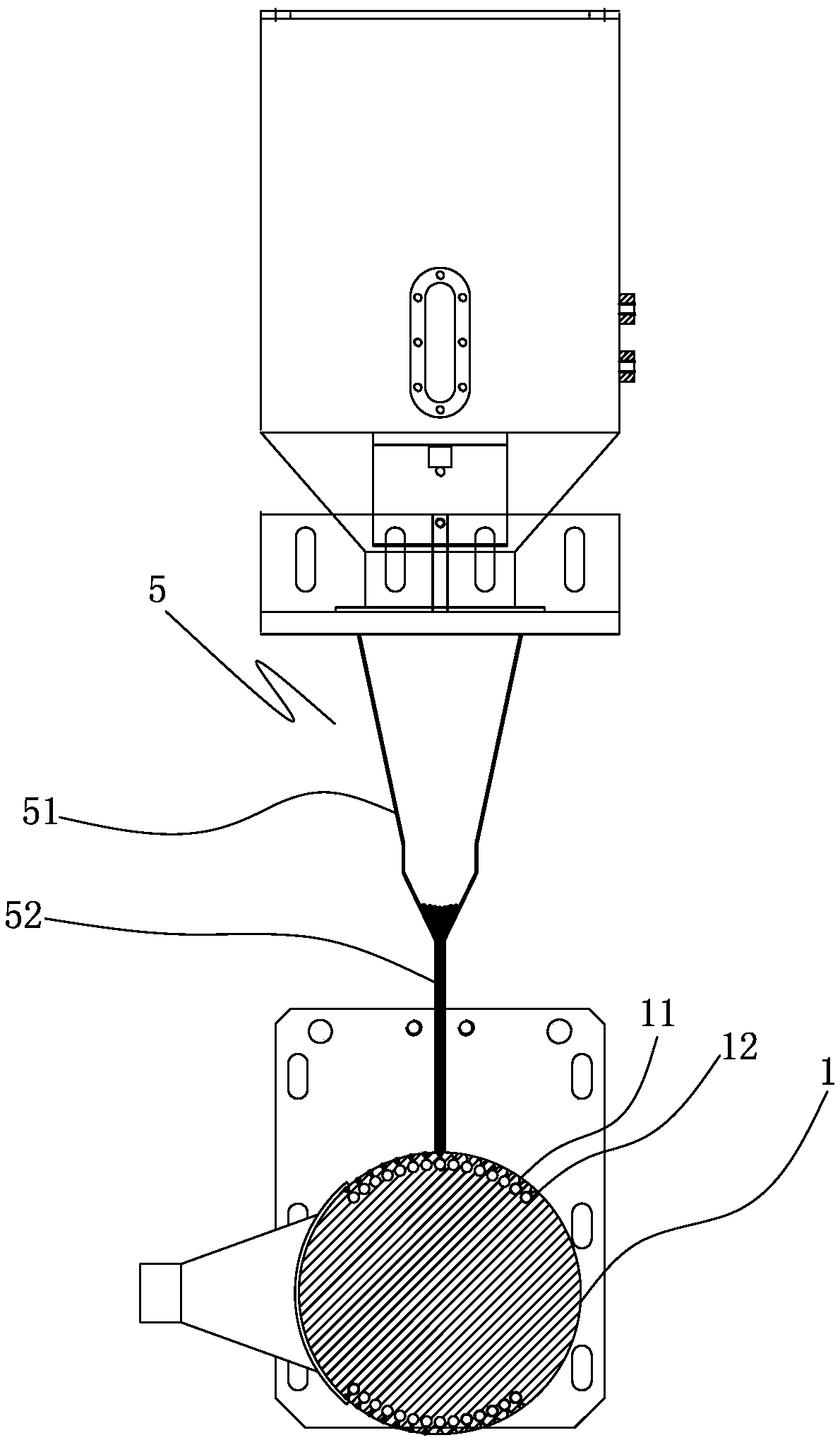

[0028] refer to Figure 1 to Figure 5 As shown, a production device for explosive pearl hygiene products, including a transfer roller 1, an adsorption plate 2, a negative pressure source, a positive pressure source, a negative pressure conveying device 3, a pressure hole device 4, a material storage box 5 and a surface layer compounding device 6 .

[0029] The hygienic article includes a surface layer and a cotton core 8 provided with a plurality of placement holes.

[0030] The transfer roller 1 can be rotatably arranged, and its outer peripheral surface is provided with a plurality of adsorption holes 11, and the interior is provided with a plurality of negative pressure passages 12 communicating with the adsorption holes 11. The adsorption holes 11 are used to receive the popping beads 7, and the plurality of adsorption holes 11 are The circular arc is arranged on the outer periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com