Oil cylinder group capable of realizing synchronous movement

A technology of synchronous motion and cylinder group, applied in the direction of fluid pressure actuation device, servo motor, mechanical equipment, etc., can solve the problems of high cost and difficult control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

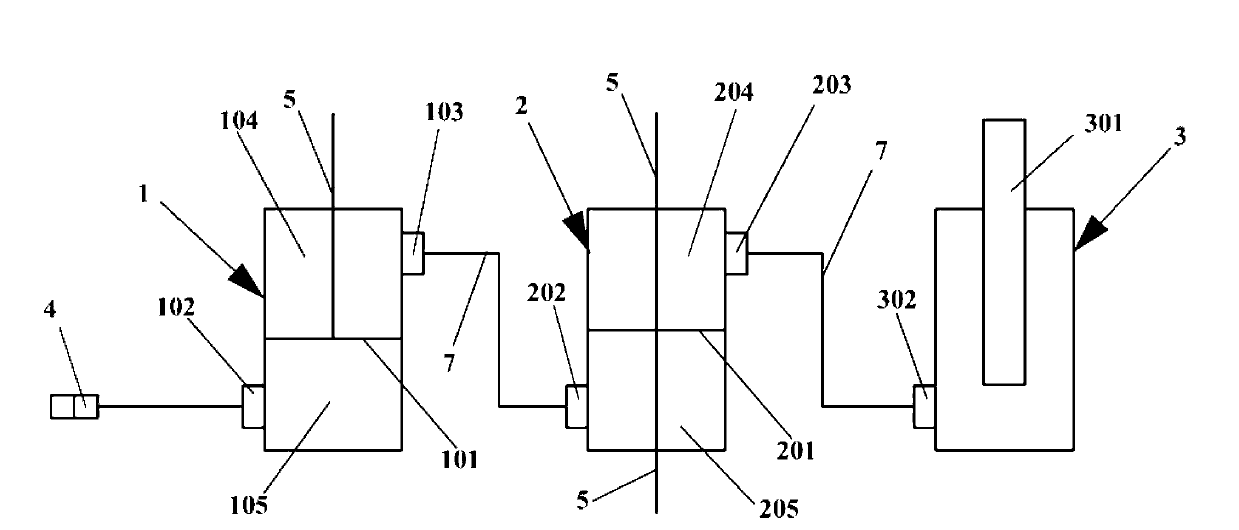

[0018] See attached figure 1 ~ attached image 3 , can realize the oil cylinder group of synchronous movement, comprise single piston rod oil cylinder 1, one or more double piston rod oil cylinders 2, plunger oil cylinder 3 and reversing valve 4; Said reversing valve 4, single piston rod oil cylinder 1, double The piston rod oil cylinder 2 and the plunger oil cylinder 3 are connected in turn; the single piston rod oil cylinder 1 and the double piston rod oil cylinder 2 are provided with two main oil ports, and the cylinder wall of the plunger oil cylinder 3 is provided with a main oil port. Oil port; each main oil port of the single piston rod cylinder 1, double piston rod cylinder 2 and plunger cylinder 3 is provided with a compensation system.

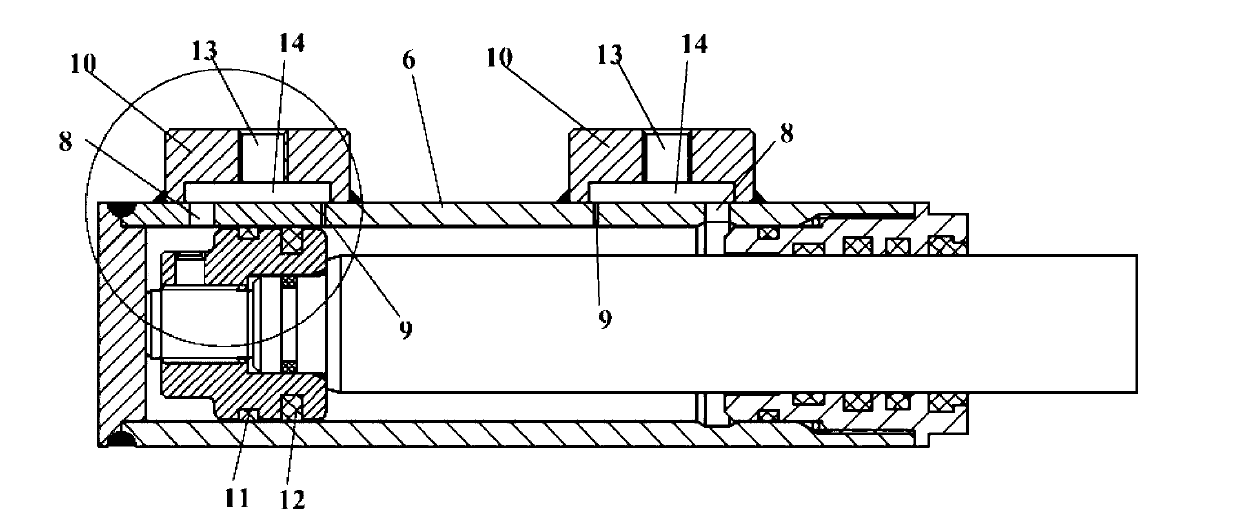

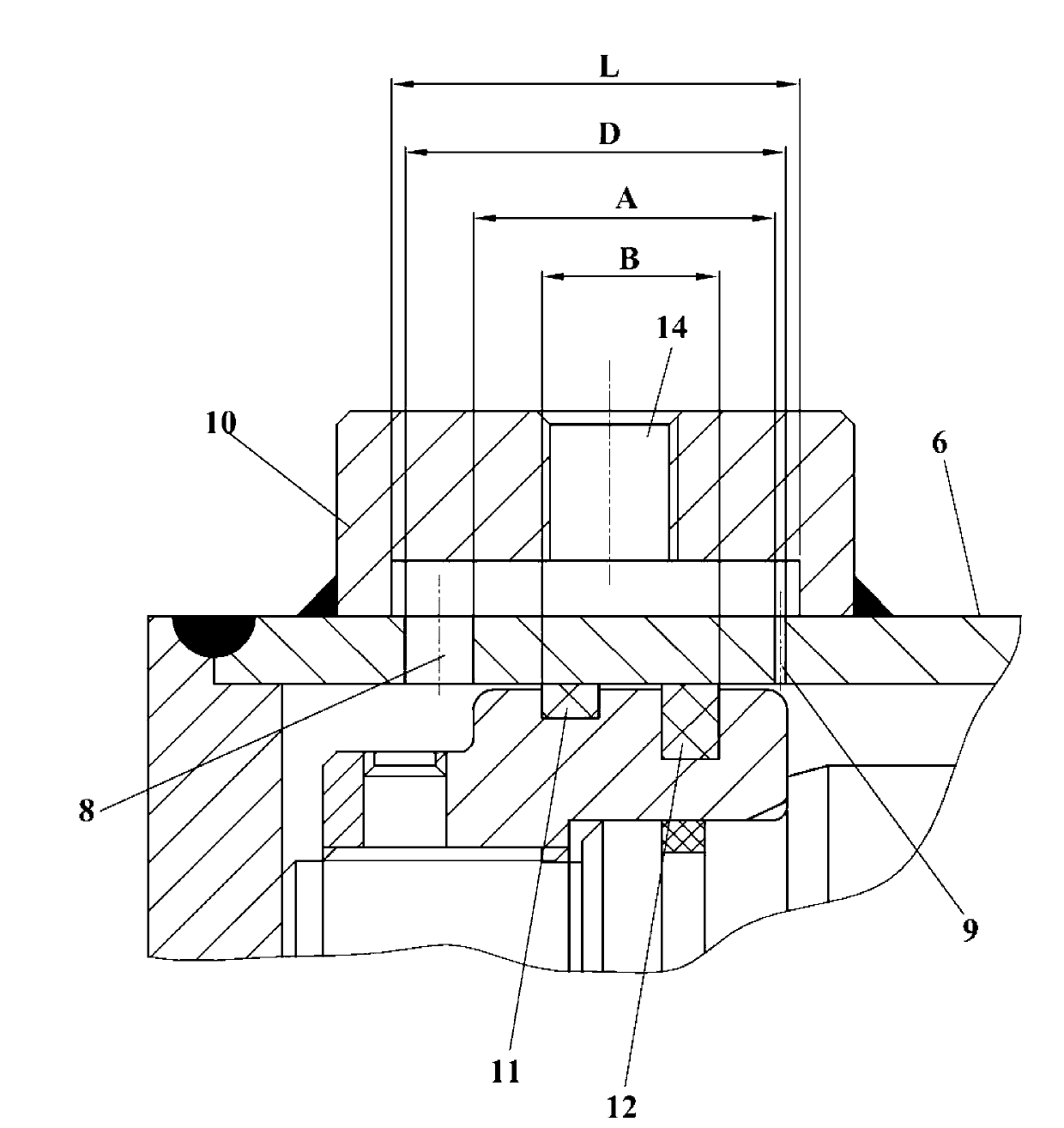

[0019] The first piston 101 is arranged inside the single-piston rod oil cylinder 1, and a piston rod 5 is arranged on the first piston 101, and first main oil cylinders are respectively arranged at both ends of the cylinder wall 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com