Automatic pasting apparatus for hook-and-loop fastener on safety helmet

An automatic sticking, Velcro technology, applied in hats, hat products, applications, etc., can solve the problem of unrealized picking and sticking of finished Velcro, and achieve the effect of ensuring product sticking quality, easy implementation, and saving human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

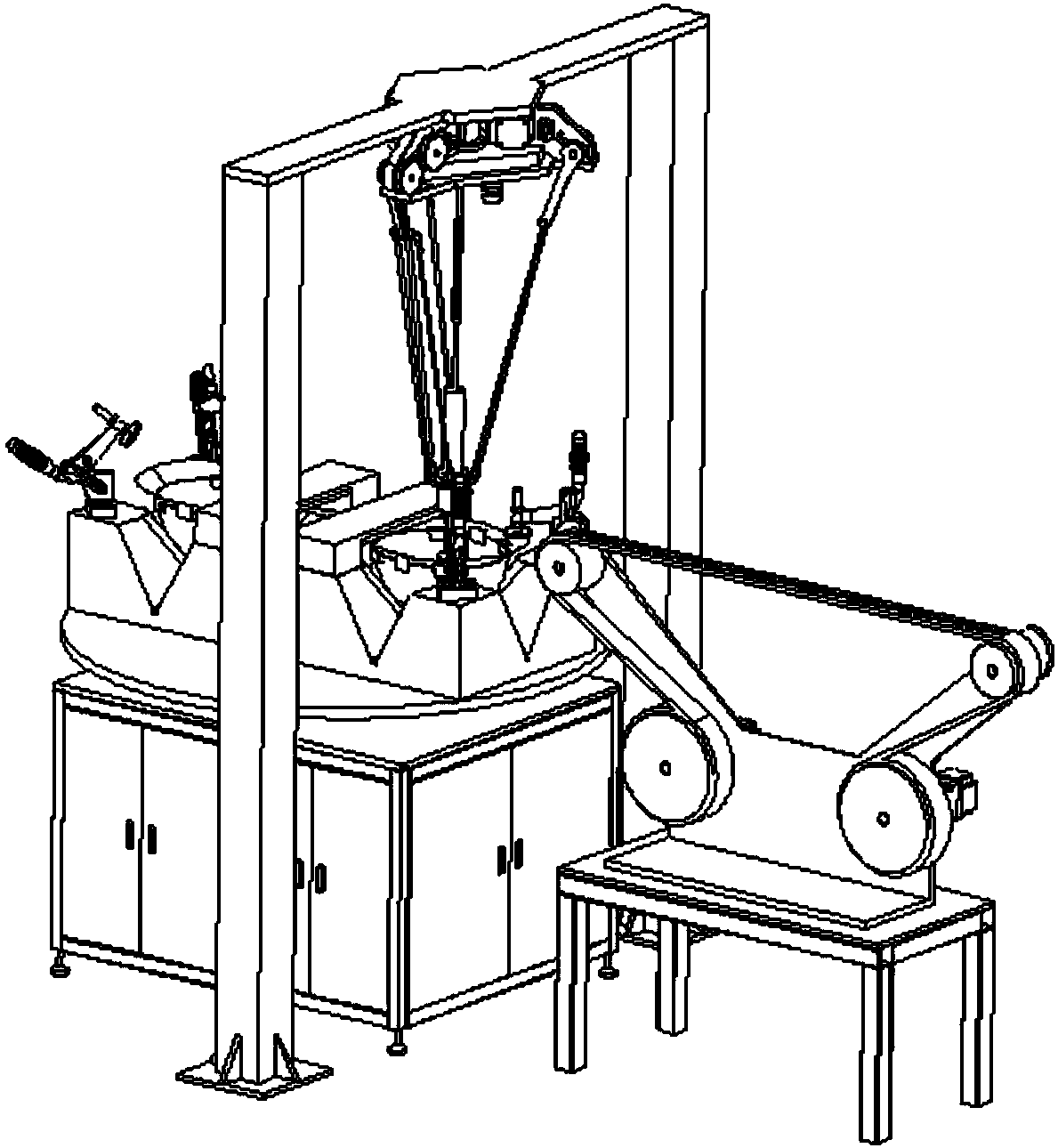

[0021] This embodiment is an automatic sticking device for helmet velcro. By controlling the motor and the parallel robot, the automatic feeding, picking, sticking and pressing of the helmet velcro can realize the automatic production of the helmet velcro sticking.

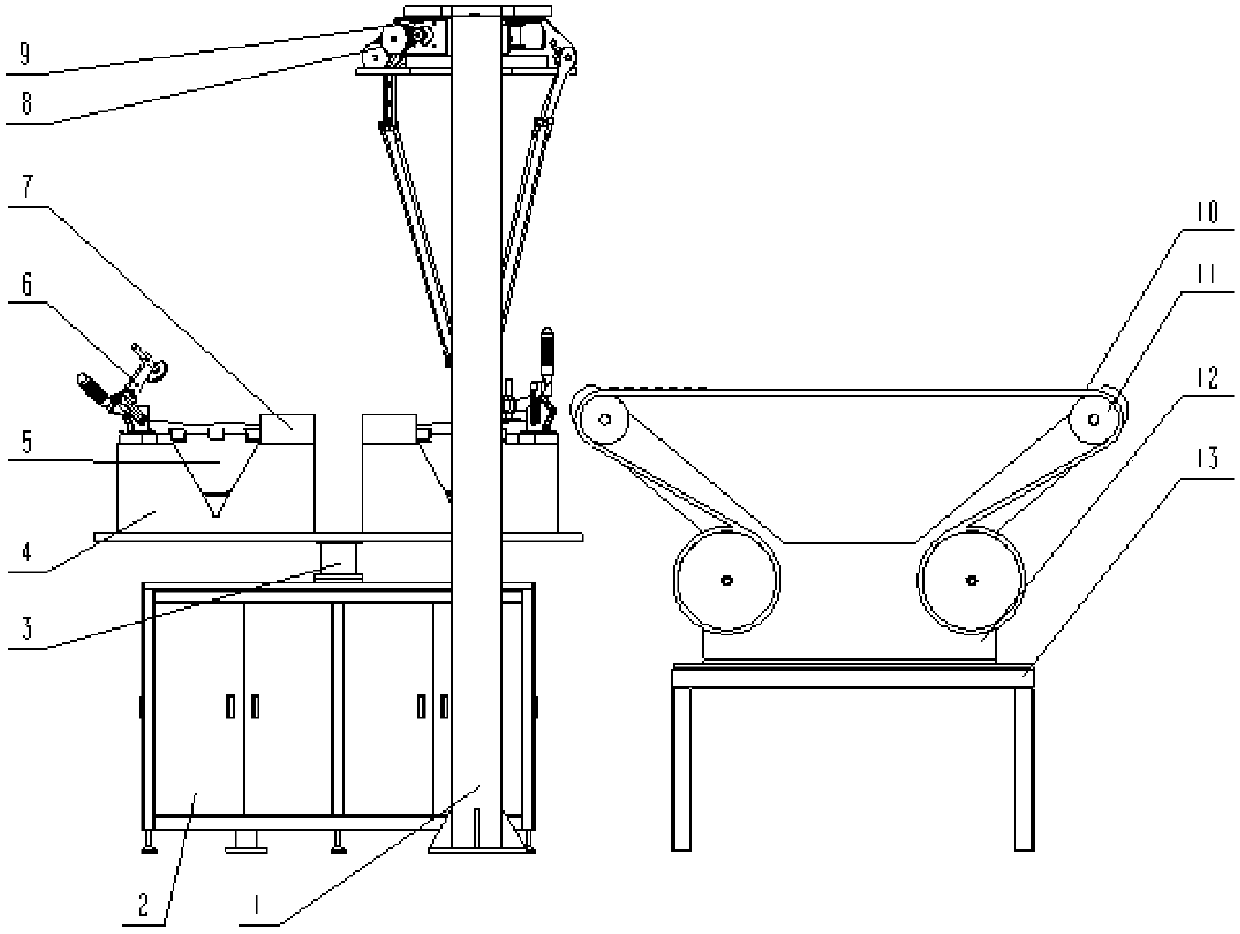

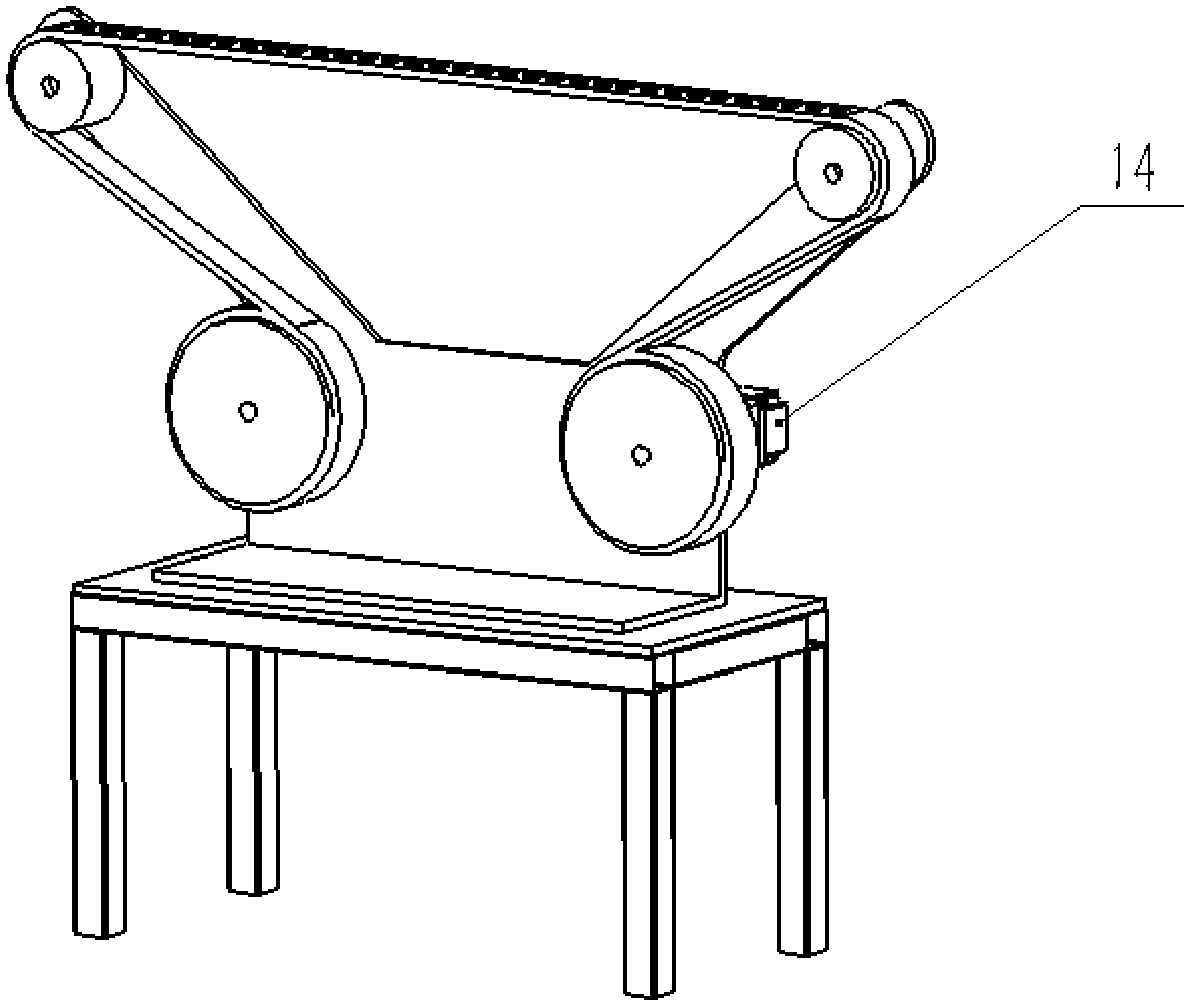

[0022] refer to Figure 1 to Figure 6 , the automatic sticking device for helmet velcro in this embodiment is composed of a feeding mechanism, a pasting workbench, a parallel robot and an electric control system; wherein, the feeding mechanism includes a motor mounting frame 12, a base 13, a first motor 14, a transmission mechanism 11. Velcro strap 10, the motor mounting frame 12 is installed on the base 13, the first motor 14 is fixed on the motor mounting frame 12, the transmission mechanism 11 is installed with the first motor 14, and the Velcro tape 10 is wound on the transmission mechanism 11 . The two motors rotate to drive the transmission mechanism, and the transmission mechanism 11 drives the Velcro tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com