Telescopic component and support for engineering machinery and concrete pump vehicle with the support

A technology of engineering machinery and components, which is applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problems of complex structure of multi-stage telescopic oil cylinder, difficult arrangement of oil cylinder oil pipeline, troublesome processing and arrangement, etc., and achieves easy processing and Layout, save manpower and production costs, control the effect of simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

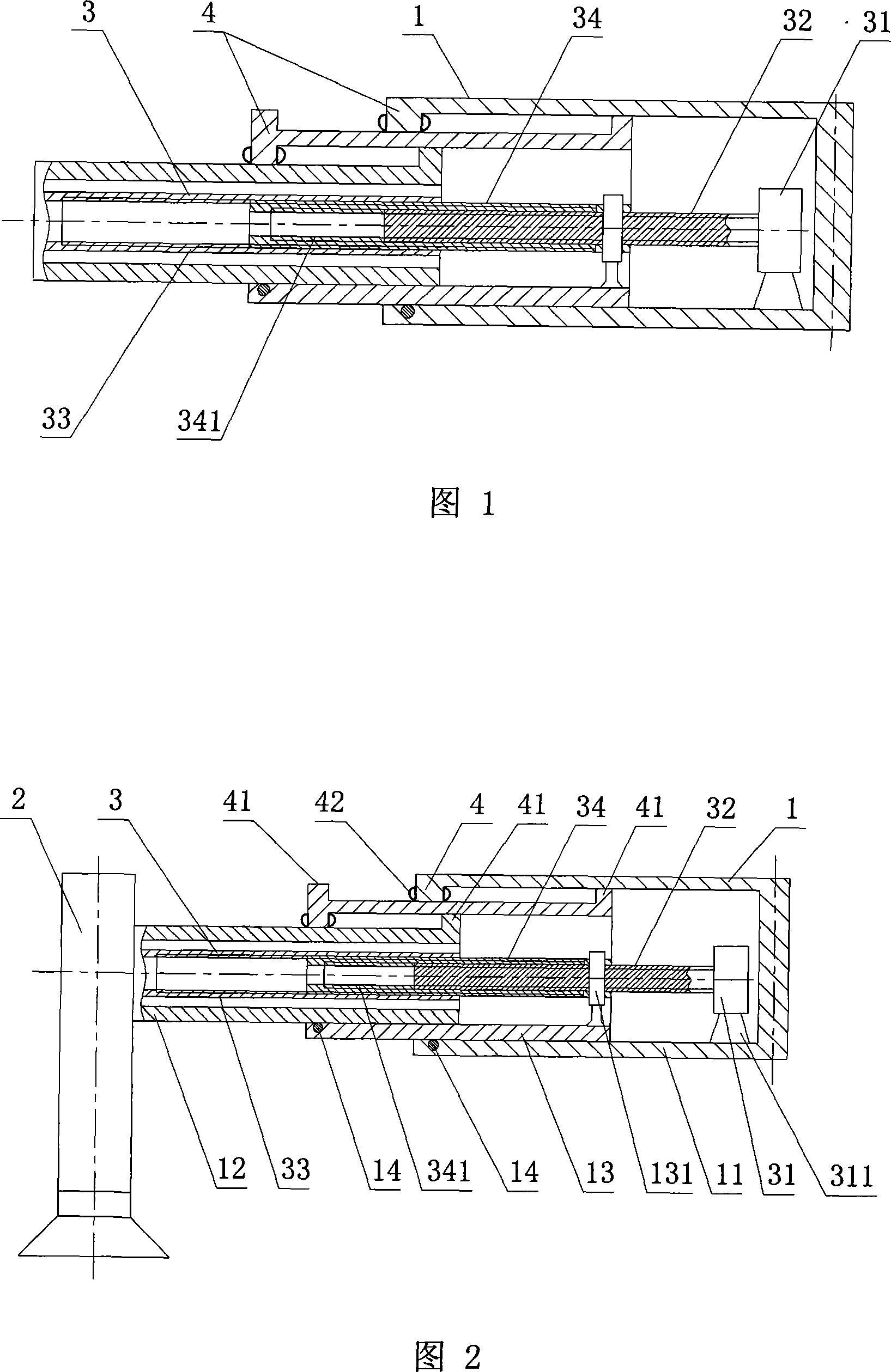

[0048] Embodiment 1: As shown in Figure 2, a telescopic outrigger for engineering machinery of the present invention includes a telescopic sleeve assembly 1, one end of which is provided with a vertically telescopic supporting foot assembly 2, and the other One end is connected with the bracket on the chassis 24 of the construction machinery. The sleeve assembly 1 is equipped with a screw mechanism 3 that can drive the sleeve assembly 1 to expand and contract and a stop device 4 that limits the expansion and contraction of the sleeve assembly 1. The screw mechanism 3 includes the original A motor 31, a circular shaft 32 with external threads and a hollow cylinder 33 with internal threads, the output shaft of the prime mover 31 is connected to the end of the circular shaft 32, and the base 311 of the prime mover 31 is fixed in the casing assembly 1 One end away from the supporting foot assembly 2 , the other end of the bushing assembly 1 is fixedly connected to the hollow cylind...

Embodiment 2

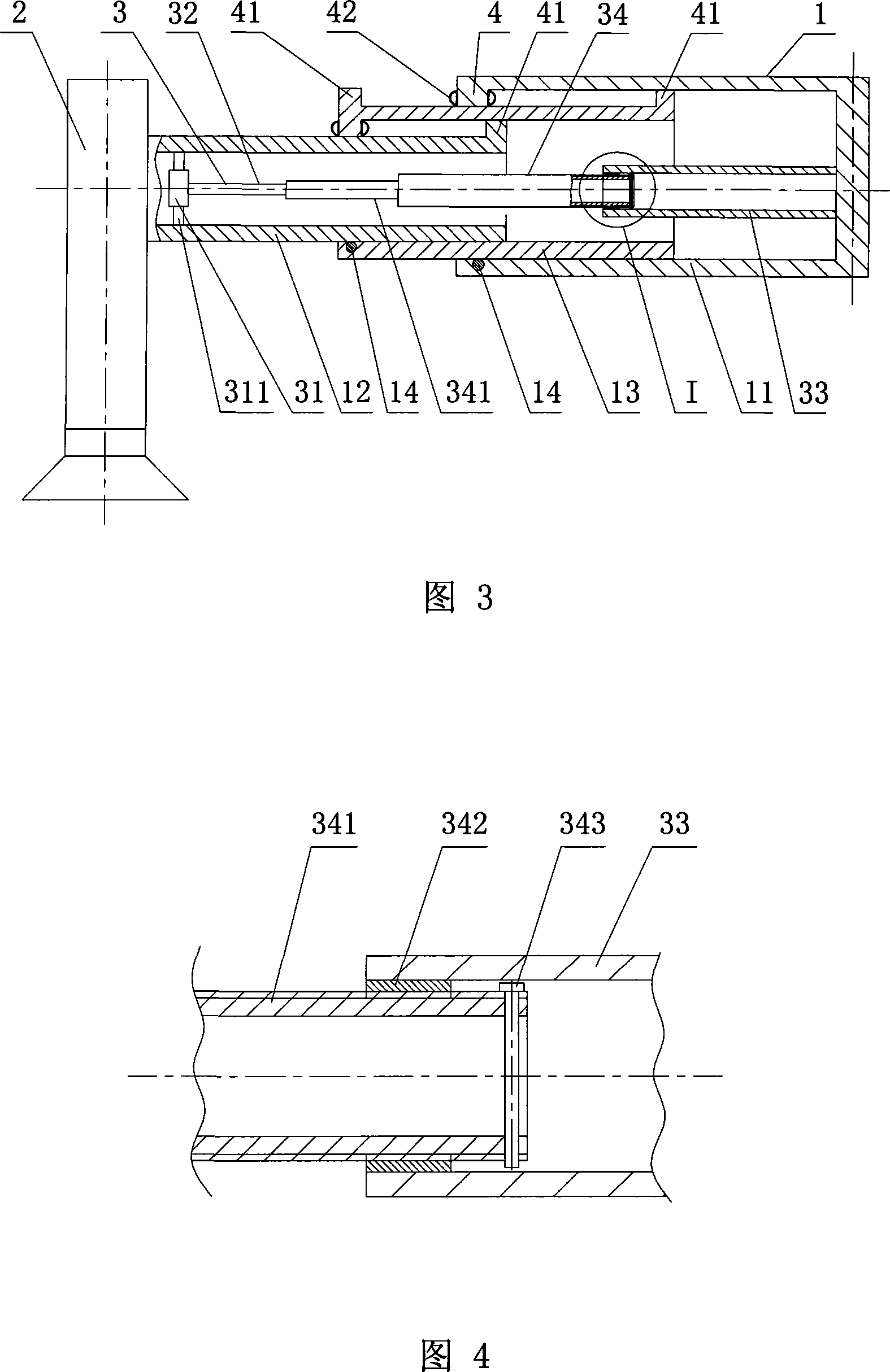

[0050] Embodiment 2: As shown in Figure 3 and Figure 4, a telescopic outrigger for construction machinery according to the present invention includes a telescopic sleeve assembly 1, and one end of the sleeve assembly 1 is provided with a vertically telescopic supporting foot assembly 2. The other end is connected to the bracket on the chassis 24 of the construction machinery. The sleeve assembly 1 is equipped with a screw mechanism 3 that can drive the sleeve assembly 1 to expand and contract and a stop device 4 that limits the expansion and contraction of the sleeve assembly 1. The screw mechanism 3 includes a prime mover 31, a circular shaft 32 with external threads and a hollow cylinder 33 with internal threads, the output shaft of the prime mover 31 is connected to the end of the circular shaft 32, and the base 311 of the prime mover 31 is fixed on the sleeve One end of the assembly 1 is close to the supporting foot assembly 2 , and the other end of the sleeve assembly 1 is...

Embodiment 3

[0052] Embodiment 3: A telescopic outrigger for engineering machinery according to the present invention has basically the same structure as that of Embodiment 2, except that the installation position of the prime mover 31 is different. As shown in Figure 5, the output shaft of the prime mover 31 is connected to the end of the hollow cylinder 33, the base 311 of the prime mover 31 is fixed on the end of the bushing assembly 1 away from the support foot assembly 2, and the other end of the bushing assembly 1 It is fixedly connected with the round shaft 32.

[0053] The concrete pump truck of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

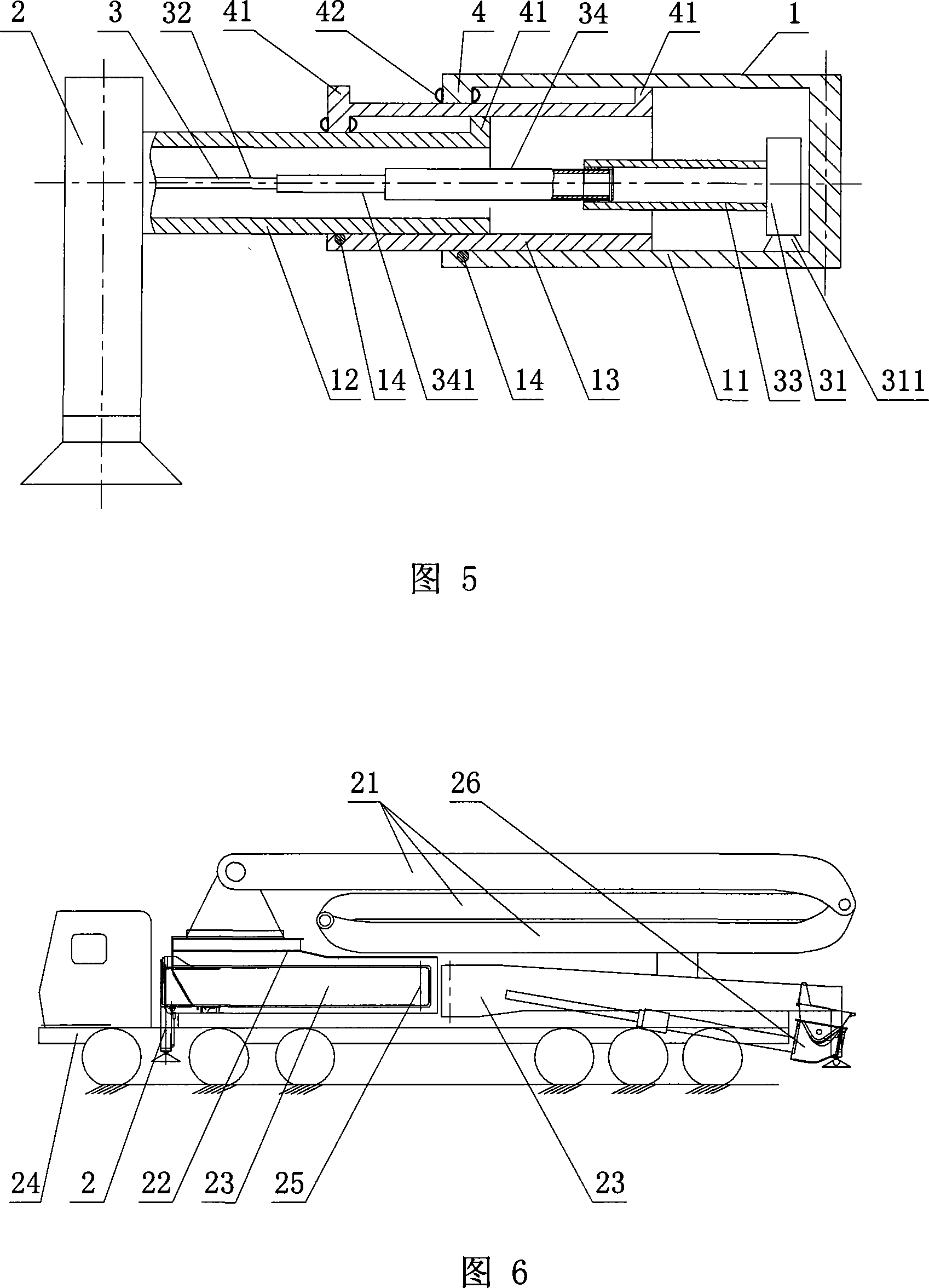

[0054] As shown in Fig. 6 and Fig. 7, a concrete pump truck of the present invention includes a chassis 24, a pumping mechanism 26 installed on the chassis 24, a boom system 21 and a supporting mechanism 22, and the supporting mechanism 22 includes four o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com