Detachable automatic sand adding sand tank, combined sand tank and realization method

An automatic sand adding and detachable technology, which is applied in loading/unloading, containers, packaging, etc., can solve the problems of difficulty in observing sand tank marking workers, marking worker injuries, high labor costs, etc., to achieve novelty and reduce transportation costs , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

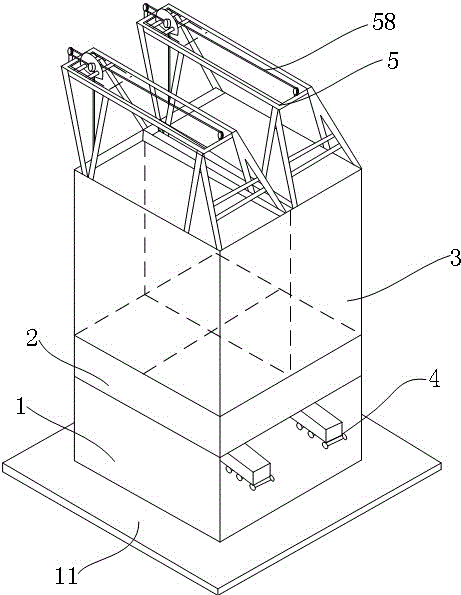

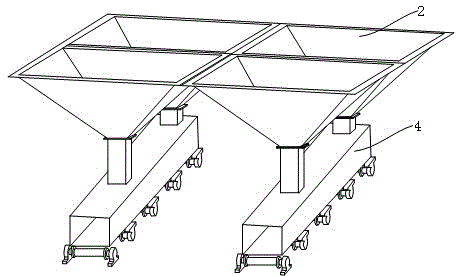

[0058] Such as figure 1 As shown, this embodiment provides a detachable automatic sand tank. In order to facilitate transportation and reduce transportation costs, the sand tank body adopts a detachable structure; Automatic bagging and sand leakage, and then transported to the construction site by the conveyor 4, realizing the automation and high efficiency of the entire sand adding operation, effectively overcoming the defects of the existing technology, the detachable structure design and the automatic structure based on this structure The novelty of the sand loading mechanism is self-evident, and in the same field or the technology of the similar field, the present invention is very creative and practical.

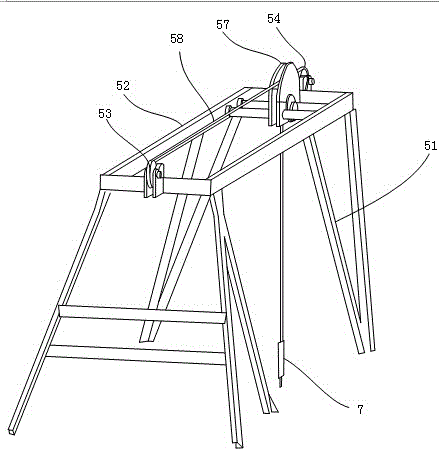

[0059] In order to make those skilled in the art have a clearer understanding and understanding of the structure of each component and the connection relationship and positional relationship between each component in the present invention, the present invention will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com