Hydraulic piling machine pile controller

A hydraulic and hydraulic cylinder technology, applied in the field of control devices for prefabricated piles, can solve problems such as changes in the level of the working platform, affecting construction efficiency and safety, and affecting the construction quality of foundation piles, and achieves high orientation, simple structure, and transmission. Stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

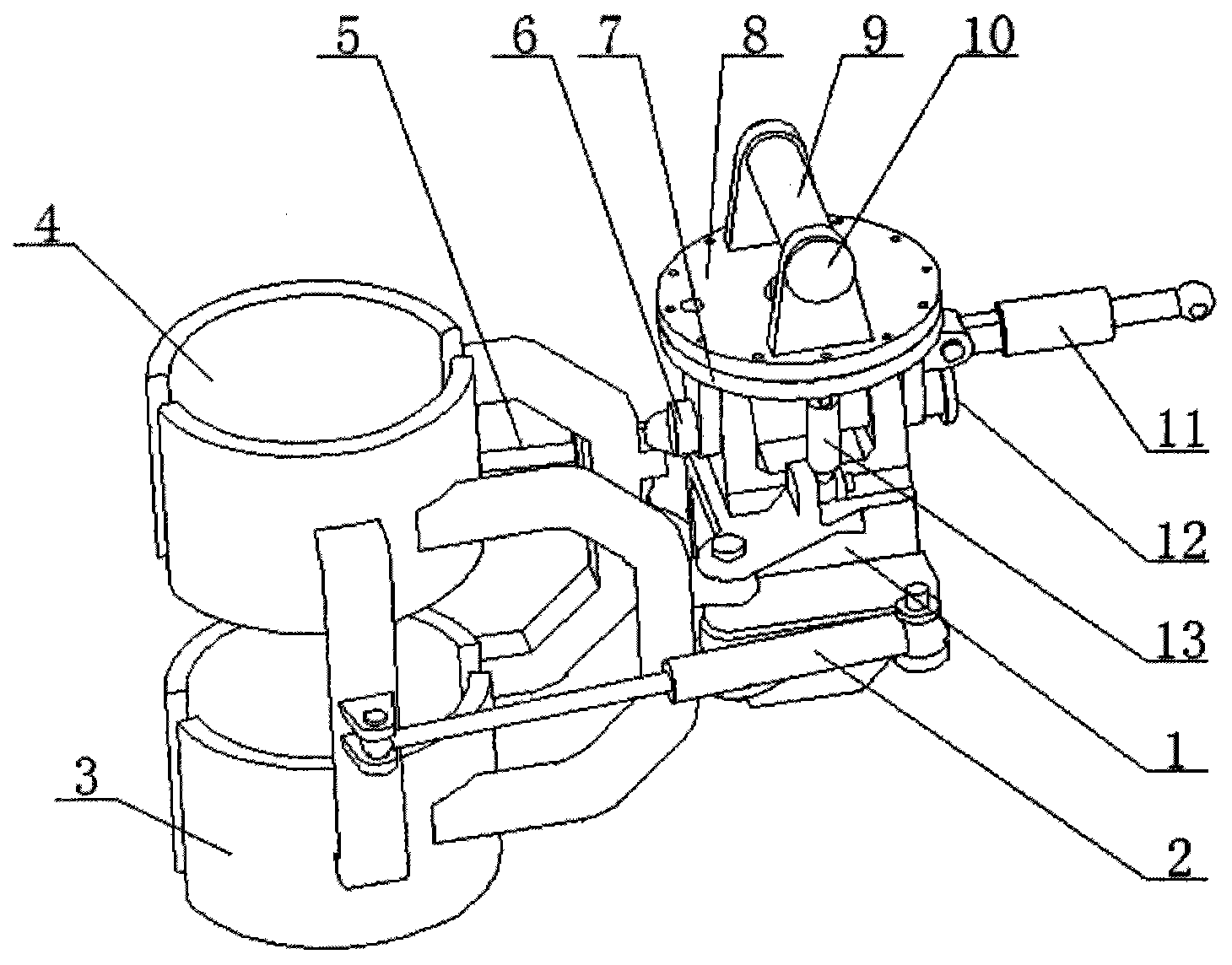

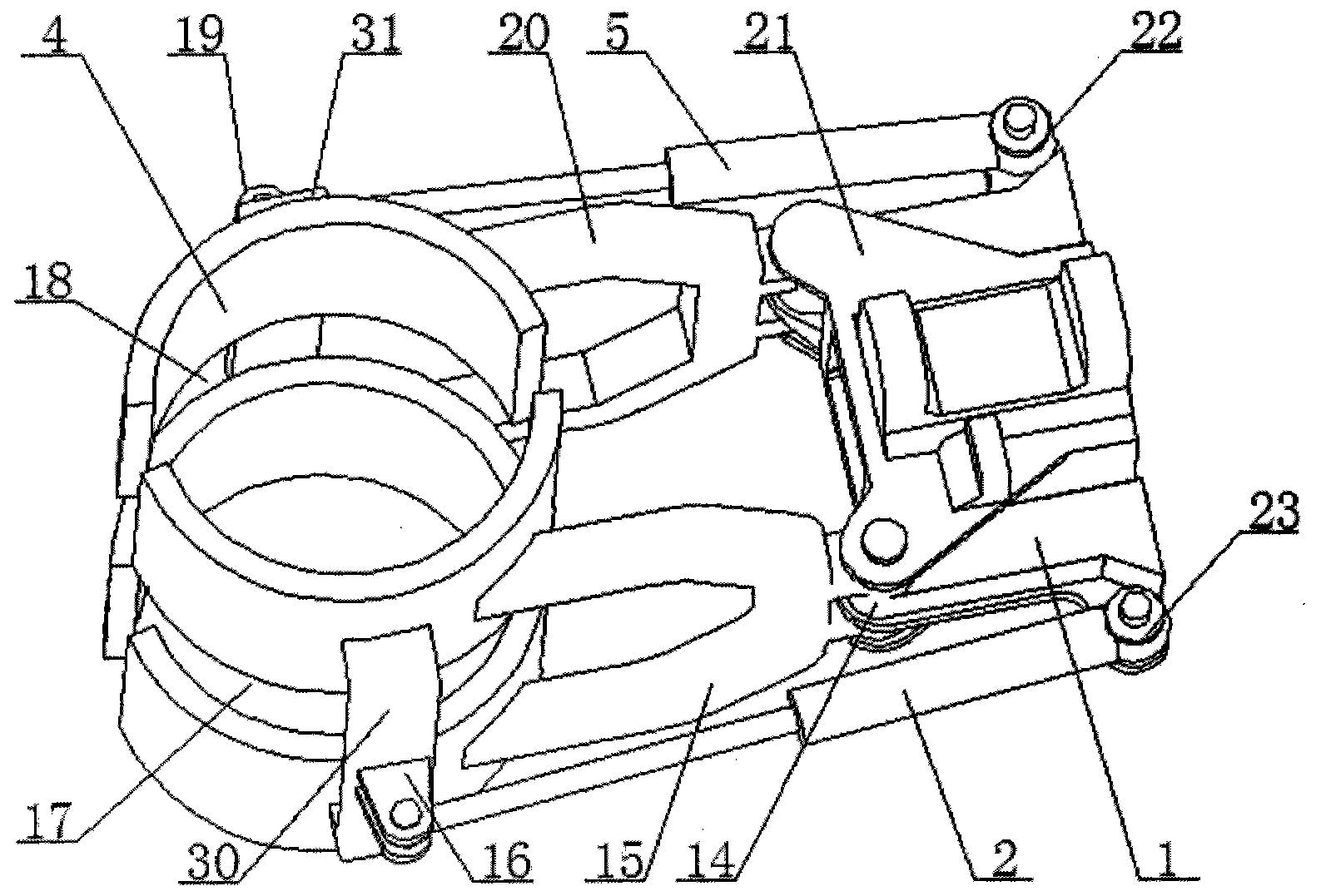

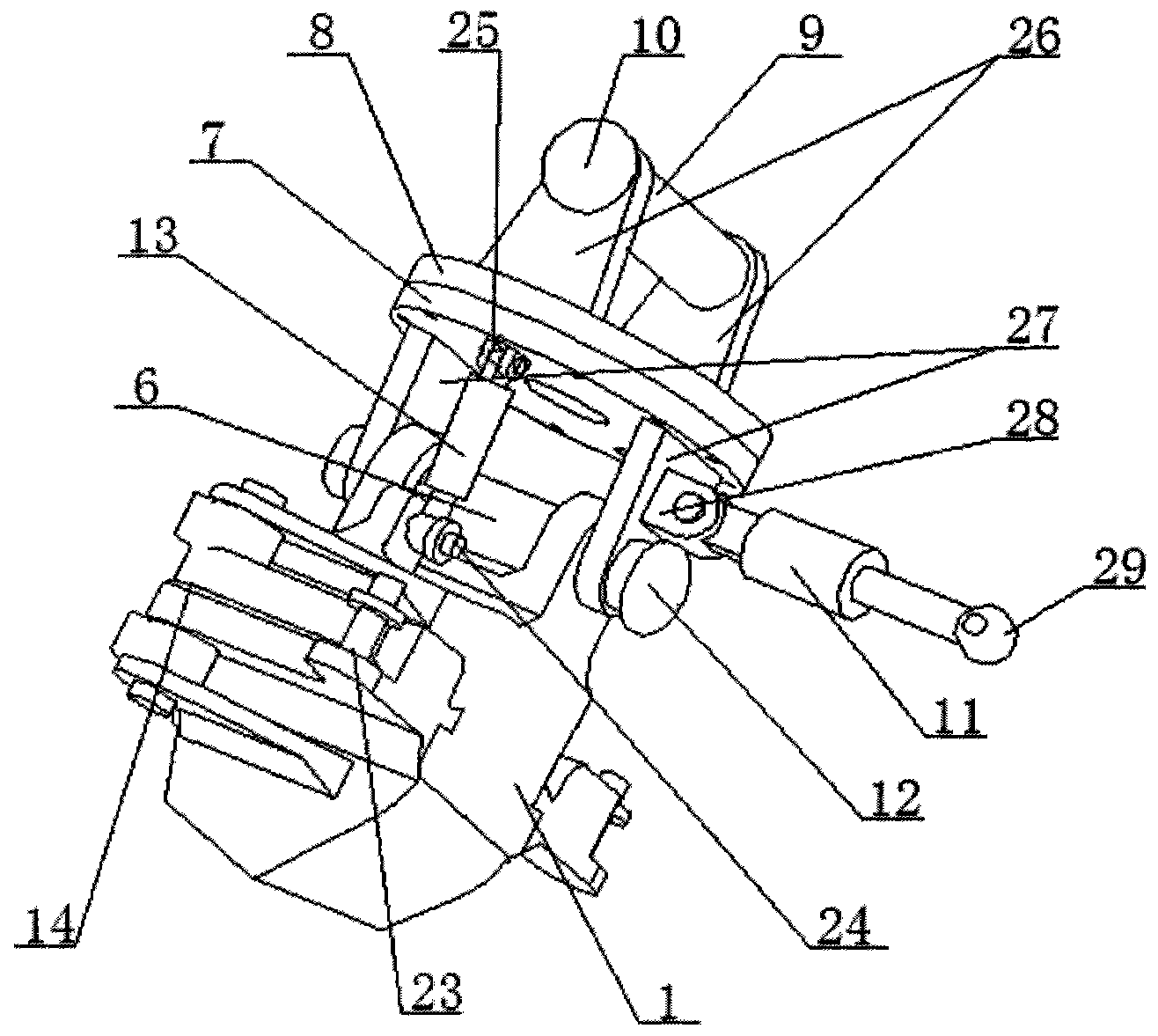

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

[0025] see Figure 1-5 , the specific embodiment is realized by adopting the following technical scheme, which includes a pile controller box and a pile controller vertical adjustment mechanism connected thereto, and the pile controller box includes a control box 1, and the control box 1 is provided with a left swing arm hinged ear 21 and a right swing arm hinged ear 14 as mirror images on both sides of 1, the clamping mechanism installed on the left swing arm hinged ear 21 and the right swing arm hinged ear 14, the pile control device adjusting The vertical mechanism includes a lower flange 7 that rotates with the control box 1. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com