Anti-blocking molybdenum powder processing pulverizer

An anti-clogging and pulverizer technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of easy clogging, etc., and achieve the effect of smooth discharge, simple structure, and sufficient crushing and grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

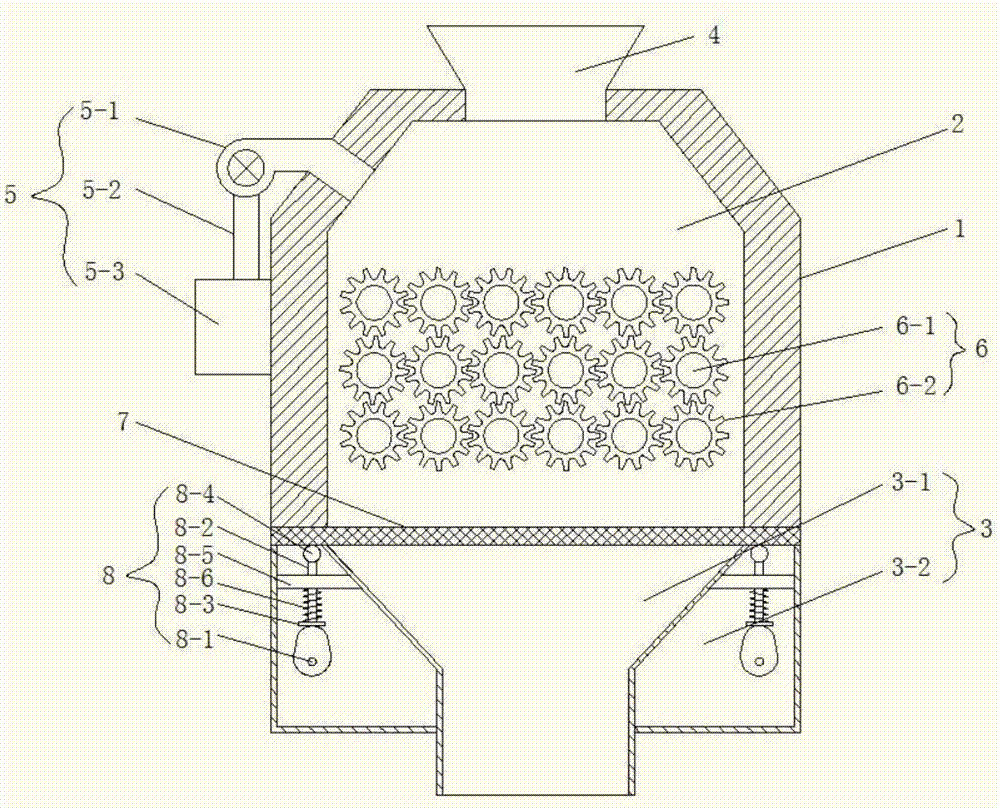

[0020] like figure 1 As shown, this embodiment provides an anti-clogging molybdenum powder processing pulverizer, including a casing 1, in which a crushing chamber 2 and a discharge chamber 3 are sequentially arranged from top to bottom, and the crushing chamber 2 and the discharge chamber 3 is provided with a filter plate 7, the crushing chamber 2 is provided with a crushing mechanism 6, and the discharge chamber 3 includes a funnel-shaped discharge chamber 3-1 and a vibration chamber 3-1 evenly distributed on both sides of the discharge chamber 3-1. 2. Both vibration chambers 3-2 are provided with the same vibration mechanism 8. The vibration mechanism 8 includes a cam 8-1 and a cylindrical push rod 8-2 arranged above the cam 8-1. The push rod 8-2 The bottom is connected with a stopper 8-3 that is in contact with the cam 8-1, and the top of the push rod 8-2 is connected with a hammering ball 8-4 for hitting the filter plate 7, and the diameter of the hammering ball 8-4 is la...

Embodiment 2

[0023] like figure 1 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the top of the casing 1 is provided with a feed port 4, and the side wall of the casing 1 is provided with a dust removal chamber that communicates with the crushing chamber 2. Mechanism 5, the dust removal mechanism 5 includes a dust suction pump 5-1 connected to the crushing chamber 2, the dust suction pump 5-1 is connected with a conduit 5-2, and the conduit 5-2 is connected with a collection box 5 arranged on the outer wall of the casing 1 -3.

[0024] In this embodiment, when workers add raw materials at the feed inlet, the dust suction pump of the dust removal mechanism will absorb a large amount of dust in the raw materials into the collection box through the conduit, which avoids the workers from inhaling dust and ensures the environmental protection of the workers. working environment.

Embodiment 3

[0026] like figure 1 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the crushing mechanism 6 includes several groups of staggered grinding rollers 6-1, and the grinding rollers 6-1 are all provided with Smash Gear 6-2.

[0027] The two cams 8-1 are all connected with drive motors through rotating shafts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com