Circulation filling system with automatic counting function

An automatic counting and functional technology, applied in the system field, can solve problems such as trouble, low efficiency, and large errors, and achieve the effects of ensuring safety, improving efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

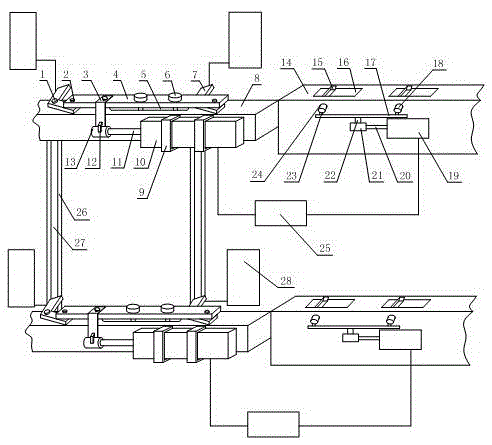

[0011] Such as figure 1 As shown, the circulating material system with automatic counting function includes an upper production line and a lower production line, the upper production line is arranged directly above the lower production line, a transmission guide rail 27 is arranged between the upper production line and the lower production line, and the two ends of the transmission guide rail 27 Respectively connected vertically with the upper production line and the lower production line, the transmission guide rail 27 is concaved to form a transmission groove 26, the transmission groove 26 communicates with the two ends of the transmission guide rail 27, the upper production line and the lower production line both include a clamping system and a support system, and the support system Comprising two guide plates 8 parallel to each other, the top of the guide plate 8 is provided with a connecting plate 4, the top of the guide plate 8 is concave to form a guide groove 5, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com