Welding head of electric spot welding machine

A technology of electric spot welding and welding head, applied in the direction of welding medium, electrode characteristics, welding equipment, etc., can solve the problems that affect the welding quality, welding head service life, unbalanced heat distribution on the welding surface, easy blackening and oxidation, etc. Long life, stable welding quality and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

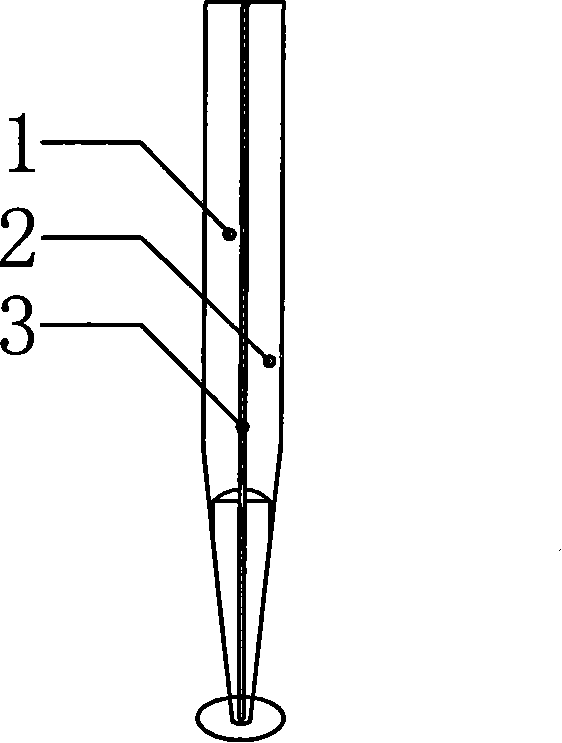

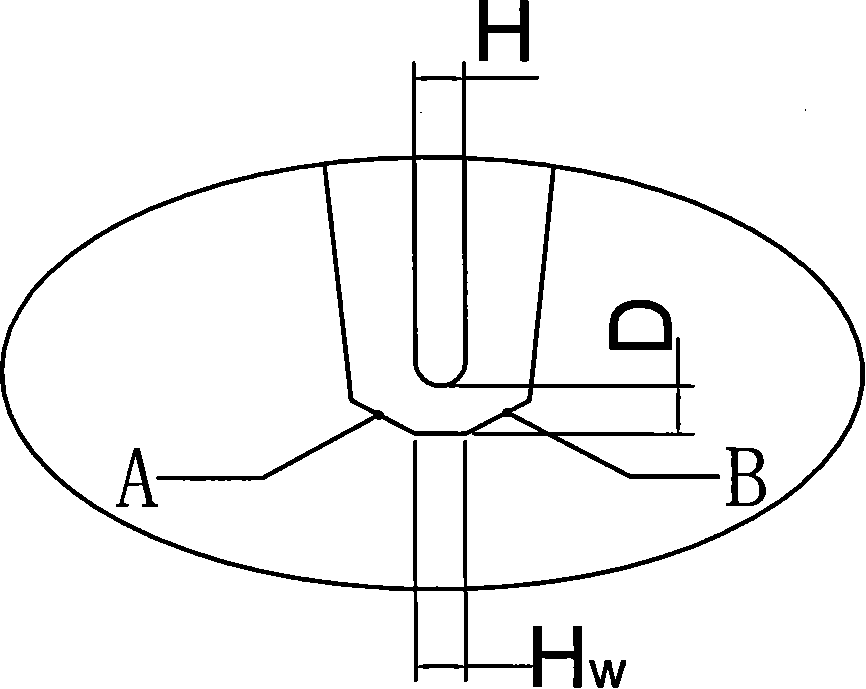

[0014] Referring to the accompanying drawings, the present invention includes two current leading ends (1, 2), and the front tip (tip) of the current leading end is connected, and it is characterized in that: the width (Hw) of the welding surface of the tip (tip) is the same as that of the two currents The width (H) of the connection surface of the leading part is equal, and the welding surface transitions with the two side chamfers.

[0015] The so-called connected specifically means continuous and uninterrupted. The chamfer can be selected between 30°-60°, generally 45°.

[0016] During the specific implementation of the present invention, a cylindrical refractory metal is cut longitudinally and equally divided into two current guiding parts (1, 2); D), the middle of which is fixed with insulating adhesive or other sticky insulators (3); then according to the needs of the welding workpiece, the welding surface is formed by means of cutting and grinding at the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com