On-line detection device and method for surface roughness of strip steel

A technology of surface roughness and detection method, applied in length measuring device, image enhancement, instrument, etc., can solve problems such as low efficiency, inability to monitor strip in real time, time difference, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

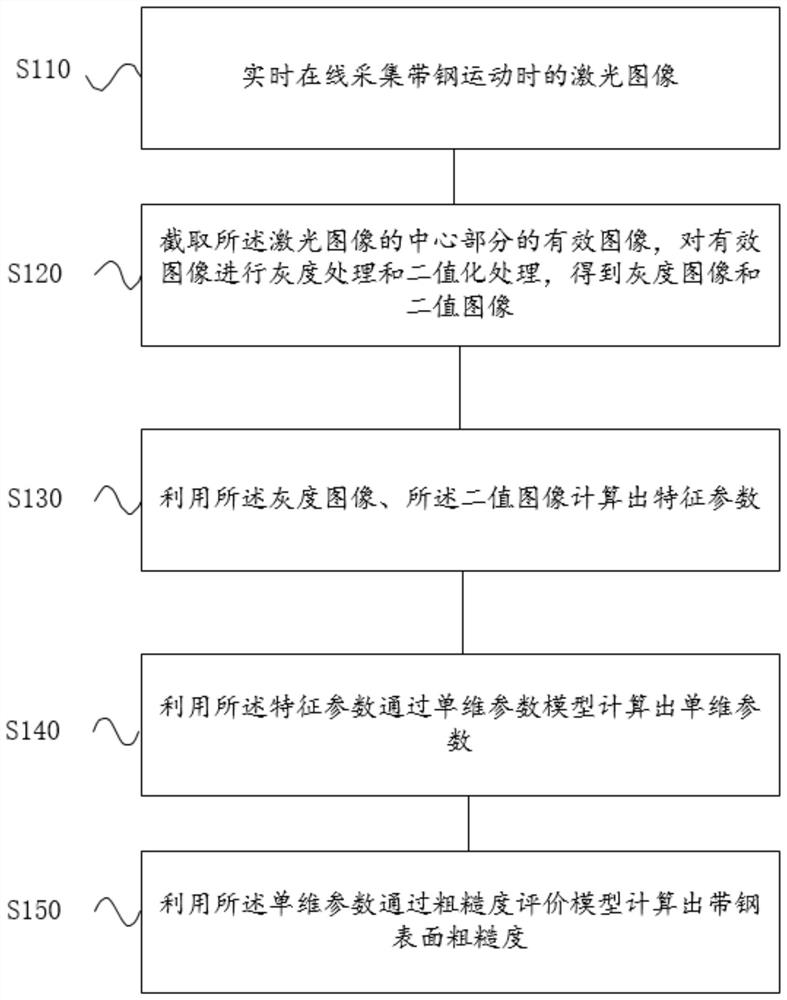

[0053] like figure 1 As shown, the present embodiment is a method for online detection of strip surface roughness, the method comprising:

[0054] S110, real-time online collection of laser images of the steel strip during movement;

[0055] S120. Intercepting the effective image of the central part of the laser image, performing grayscale processing and binarization processing on the effective image to obtain a grayscale image and a binary image;

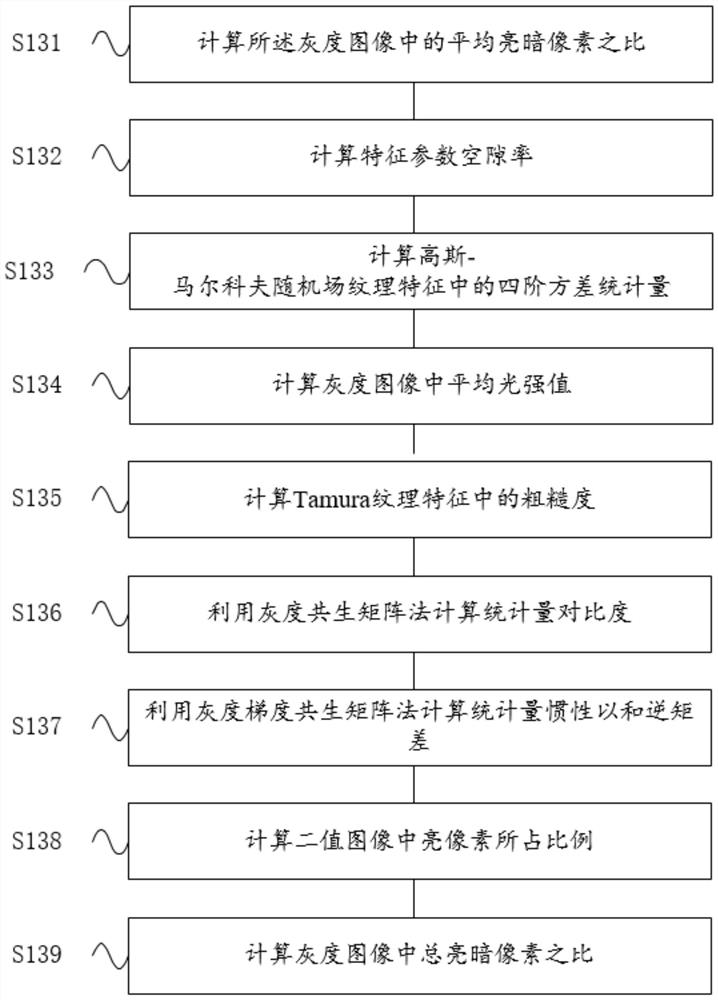

[0056] S130. Calculate feature parameters by using grayscale images and binary images;

[0057] S140. Calculate the single-dimensional parameter by using the characteristic parameter through the single-dimensional parameter model;

[0058] S150 , calculating the surface roughness of the steel strip by using the single-dimensional parameter through the roughness evaluation model.

[0059]The online detection method of strip surface roughness in this embodiment takes the characteristic parameters in the calculated laser image as i...

Embodiment 2

[0086] like Figure 1 ~ Figure 3 As shown, the present embodiment is a method for online detection of strip surface roughness, the method comprising:

[0087] S110: real-time online collection of laser images of the steel strip in motion;

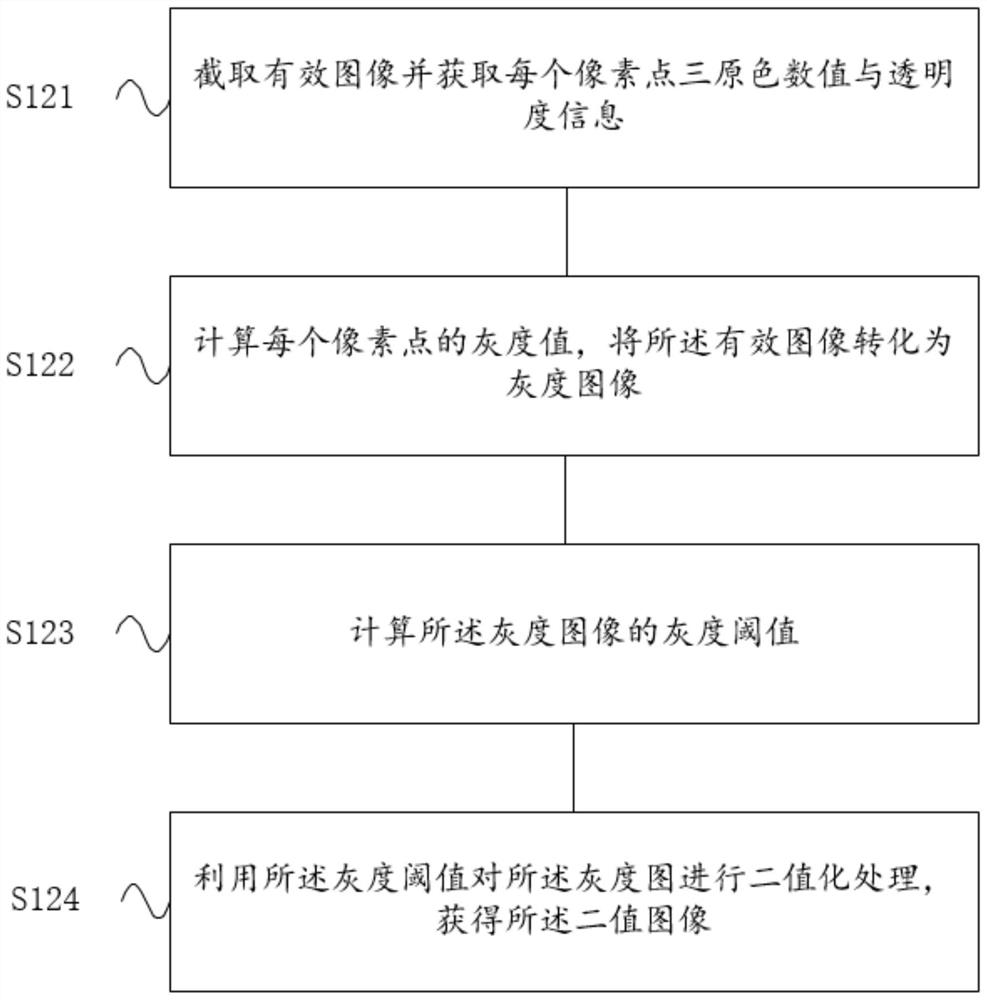

[0088] S120: Intercepting the effective image in the central part and performing average grayscale processing and binarization processing on the image; including:

[0089] S121. Intercept the effective image and obtain the three primary color values and transparency information of each pixel, and the image size after interception is 1024*1024;

[0090] S122. Obtain the grayscale value of each pixel: average the color values of the three primary colors of each pixel to obtain the grayscale value of the pixel, and convert the color image into a grayscale image. The calculation formula is as follows:

[0091] Gray(i,j)=(R(i,j)+G(i,j)+B(i,j)) / 3

[0092] Among them, Gray(i, j) is the gray value obtained by the average method, R(i, j) repr...

Embodiment 3

[0158] like Figure 4 As shown, the present embodiment provides a strip steel surface roughness on-line detection device, and the strip steel surface roughness on-line detection device can be applied to the strip steel surface roughness on-line detection method;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com