Torsion detecting rim motor

A motor and rim technology, which is applied in the field of rim motors with torque detection, can solve the problems of large distance intervals, inability to accurately detect torque, and inability to assist in timely application of force, etc., to improve ease and ease of operation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

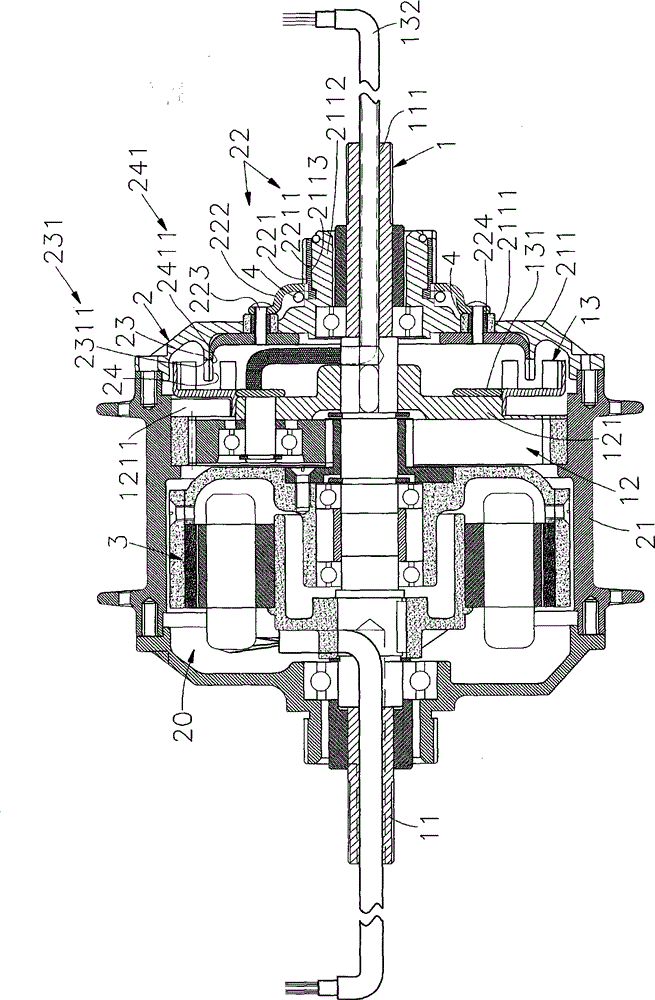

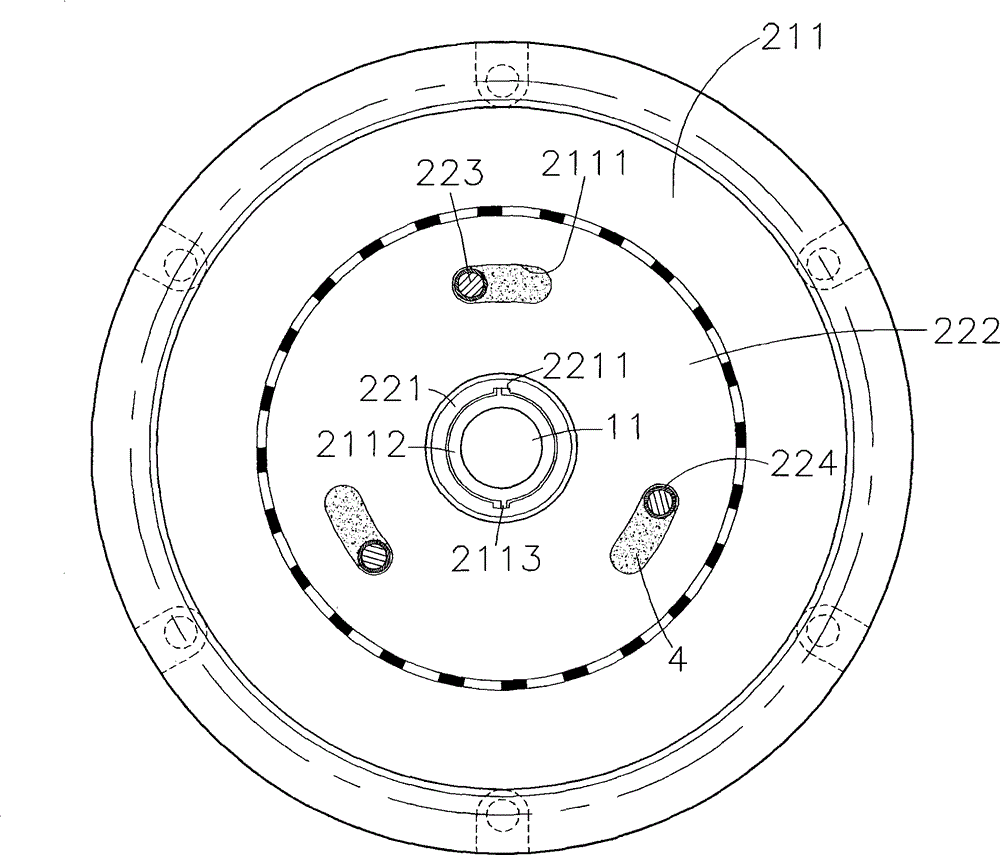

[0041] Such as figure 1 , figure 2 As shown, the present invention includes a fixed device 1, a movable device 2 driven by an external force to rotate the wheel, a power motor 3 that drives the movable device 2 to rotate, and an elastic component 4 linked by the movable device 2, wherein:

[0042] This immovable device 1 is installed on the vehicle 5, and the immobile device 1 is provided with a through groove 111 in the central shaft 11, and is provided with a reduction gear group 12 on the central shaft 11, and the reduction gear group 12 (the present invention) The reduction gear set is prior art) is a planetary gear set, including a sun gear, ring teeth and a plurality of planetary gears.

[0043] An accommodating space 20 is formed between the movable device 2 and the stationary device 1, and the movable device 2 is provided with a wheel shell 21 covering the outside of the stationary device 1 and connected to a wheel 51, one side of the wheel shell 21 A shell cover 2...

Embodiment 2

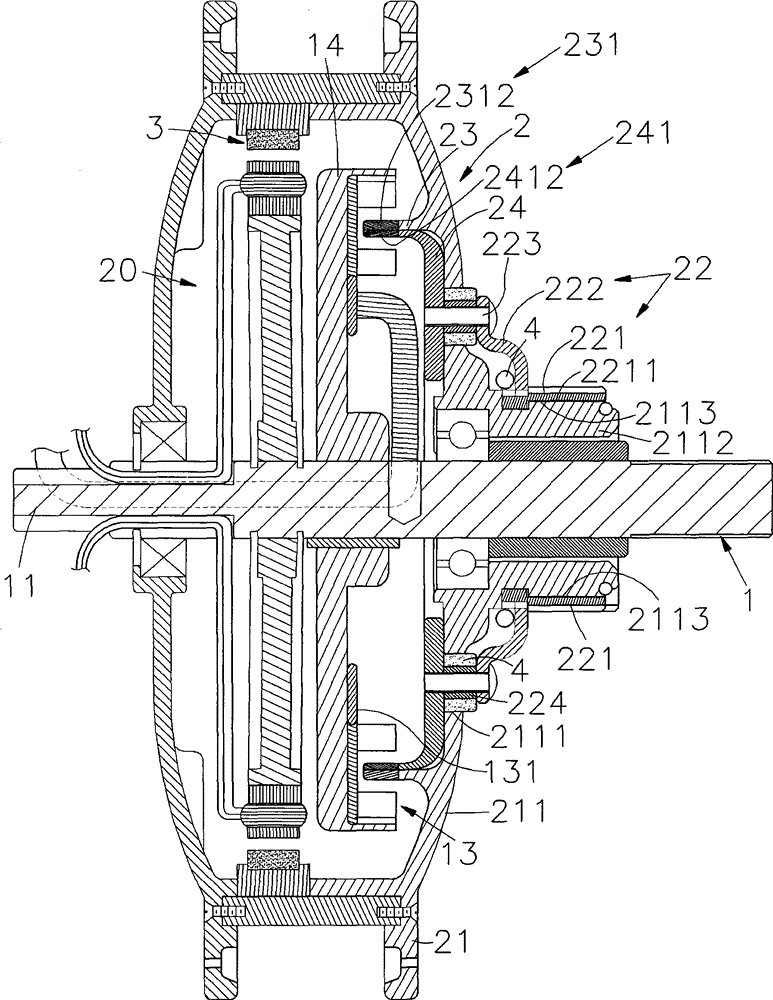

[0051] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the central shaft 11 of the immovable device 1 is fixed with a fixed frame 14, and the sensor 13 is installed on the fixed frame 14. In this way, the overall thickness of the rim motor 6 is reduced. Thinned. The driven rotating grid plate 23 of this embodiment and the first embodiment can be locked to the shell cover 211, and can also be integrally formed by the shell cover 211; moreover, the driven rotating grid plate 23 and the active rotating grid plate 24 can also be exchanged and stacked according to design requirements. Therefore, the active rotating grid plate 24 can also be locked on the shell cover 211 or made of integral molding of the shell cover 211, so that the driven rotating grid plate 23 does not Additional manufacturing and assembly are required, which not only reduces the overall thickness, but also saves manufacturing costs and assembly steps and time.

Embodiment 3

[0053] Such as Figure 4 , Image 6 , Figure 7 As shown, the fixed device 1 of this embodiment is the same as the embodiment 1. The movable device 2 includes a wheel shell 21 and a shell cover 211. One side of the wheel shell 21 is provided with a shell cover 211 for the elastic component 4 to resist. The moving module 22 includes a driven rotating disc 25 and a linking disc 222, one side of the linking disc 222 is opposite to the side of the case cover 211, and a connecting portion extending through the case cover 211 for the sprocket 26 to be fixed 2221, the active rotating grid plate 24 is fixed on the other side of the interlocking plate 222, and the sprocket 26 is located on the other side of the shell cover 211; A limiting groove 2211 is formed on the inner wall of the cover 211 , and the limiting block 2113 on the connecting portion 2221 is accommodated in the limiting groove 2211 . The interlocking plate 222 is provided with a plurality of pushing parts 2222 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com