Fluxing agent for reducing melting point of coal ash

A technology of flux and coal ash, which is applied in the direction of fuel additives, petroleum industry, solid fuel, etc., can solve the problems of difficult gasification coal, high melting point of coal ash, and high processing cost, so as to promote the formation of eutectic system and improve High-temperature fluidity, the effect of accelerating the mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

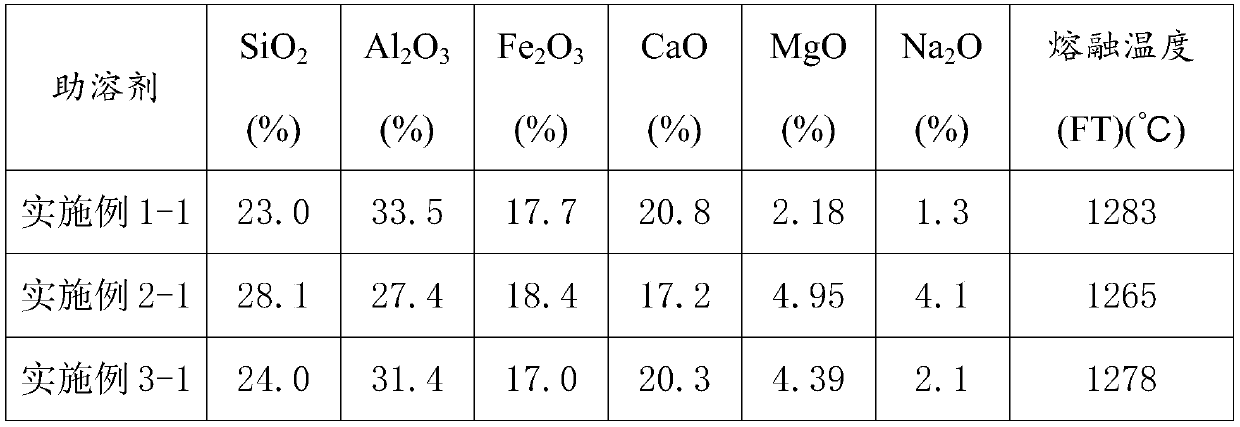

Examples

Embodiment 1

[0028] CaO powder, MgO powder, Fe 2 o 3 Powder, Na 2 O powder, K 2 The O powder is thoroughly mixed and ground to a fineness of 60 mesh sieves, and then mixed with organic hazardous waste (the organic hazardous waste is the residue produced by washing and regenerating oil during the gas purification process, and the residue is recombined min, kinematic viscosity greater than 8mm at 40°C 2 / s, calorific value is 34000kJ / kg), grind until passing through 20 mesh sieve to get powder flux.

[0029] The active ingredient contained in the flux is as follows according to the mass percentage:

Embodiment 1-1

[0031] In the process of gas purification, the residue amount produced by washing oil regeneration is 40%, CaO is 20%, MgO is 10%, Fe 2 o 3 26%, Na 2 O is 2%, K 2 O is 2%.

Embodiment 1-2

[0033] In the process of gas purification, the residue amount produced by washing oil regeneration is 60%, CaO is 10%, MgO is 5%, Fe 2 o 3 21%, Na 2 O is 2%, K 2 O is 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com