Composite modified hard asphalt and preparation method thereof

A hard asphalt, composite modification technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of less low-temperature performance analysis, high-temperature viscosity, poor fluidity, etc. The method is simple, and the high-low temperature performance is good. , Good fluidity at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

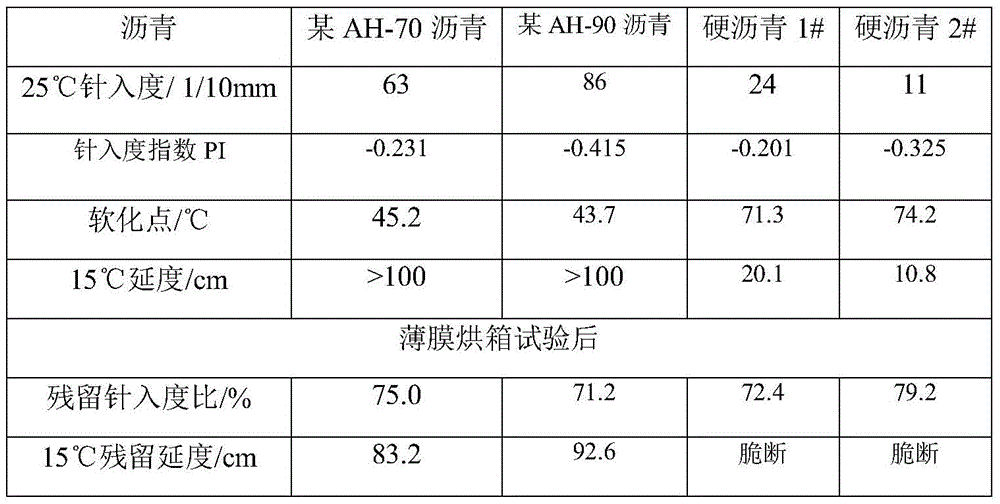

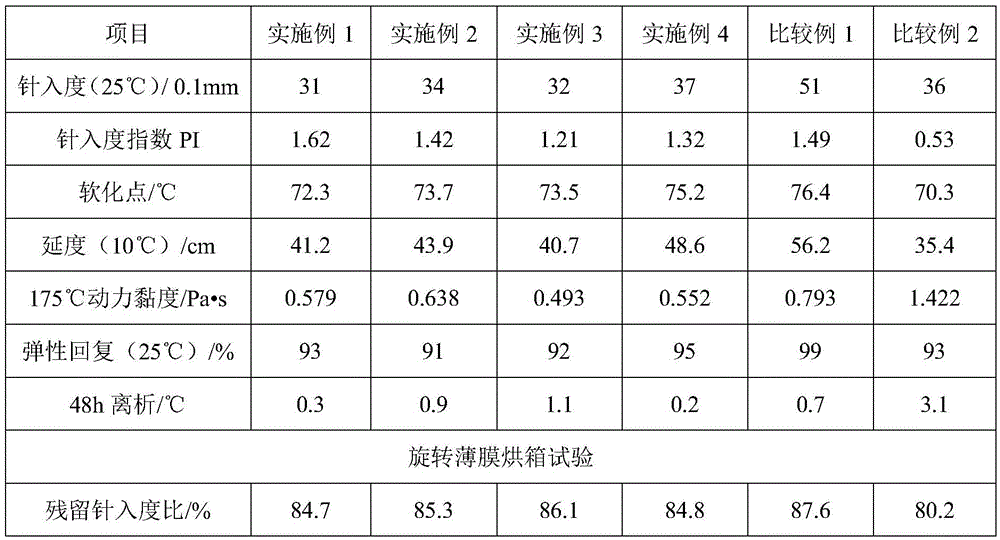

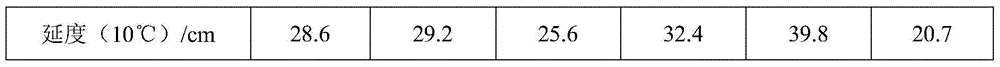

[0044]Heat 100 parts of a certain AH-70 asphalt to 135°C, add 4 parts of compatibilizer A, stir at 300rpm for 20 minutes to fully mix the two; then raise the temperature to 200°C, increase the stirring speed to 1000rpm, slowly add 15 parts of 30 waste rubber powder, and stir for 2.5 hours; then change the high-speed shearing machine, increase the speed to 4000rpm, slowly add 3 parts of SBS1301-1 modifier, and shear for 50 minutes; reduce the temperature to 180°C, and slowly add 0.2 parts of cross-linking agent NH4L agent, stirred at 700rpm for 4 hours; finally, the temperature dropped to 175°C, and the rotation speed was reduced to 300rpm, slowly added 10 parts of hard asphalt 1#, and stirred for 20 minutes. The main performance indicators of the obtained composite modified hard asphalt are shown in Table 3 .

Embodiment 2

[0046] Heat 100 parts of a certain AH-70 asphalt to 145°C, add 6 parts of compatibilizer B, stir at 400rpm for 25min to fully mix the two; then raise the temperature to 195°C, increase the stirring speed to 800rpm, slowly add 19 parts of 40 waste rubber powder, and stir for 3 hours; then change the high-speed shearing machine, increase the speed to 4500rpm, slowly add 2 parts of SBS4303-2 modifier, and shear for 45 minutes; reduce the temperature to 185°C, and slowly add 0.25 parts of cross-linking agent DY-1, stirred at 1000rpm for 3.5h; finally the temperature dropped to 180°C, reduced the speed to 500rpm, slowly added 15 parts of hard asphalt 2#, and stirred for 30min. The main performance indicators of the obtained composite modified hard asphalt are shown in table 3.

Embodiment 3

[0048] Heat 100 parts of a certain AH-90 asphalt to 130°C, add 3 parts of compatibilizer C, stir at 300rpm for 20 minutes to fully mix the two; then raise the temperature to 195°C, increase the stirring speed to 1000rpm, slowly add 17 parts of 60 waste rubber powder, and stir for 3 hours; then change the high-speed shearing machine, increase the speed to 5000rpm, slowly add 2.5 parts of SBS501 modifier, and shear for 50 minutes; reduce the temperature to 180°C, and slowly add 0.3 parts of cross-linking agent DY- 2. Stir at 1000rpm for 3 hours; finally, at 185°C, reduce the rotation speed to 400rpm, slowly add 10 parts of hard asphalt 2#, and stir for 20 minutes. The main performance indicators of the obtained composite modified hard asphalt are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com