Boriding agent for boriding on metallic titanium surface and boriding technique

A technology of boronizing agent and metal titanium, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of unsatisfactory hardness of boronizing layer, no further curing treatment, easy to fall off, etc., to achieve Recyclable usable period, less fluoride content, good fluidity at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

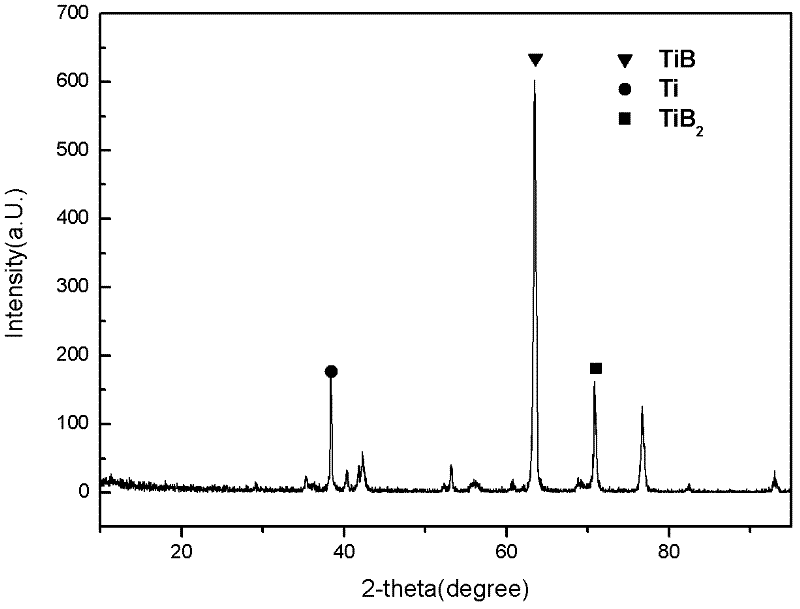

[0039] Boronizing agent composition: 28% Na 2 B 4 o 7 , 20%H 3 BO 3 , 17%B 4 C, 15% KCl, 18% NaCl, 2% KBF 4 .

[0040] Boronizing process: first cut the titanium alloy plate into a profile of 15mm*15mm*3mm (length*width*thickness), then use No. 150 sandpaper to roughly grind and polish the profile, and then use No. 600, No. 800 and No. 1200 Finely grind and polish with sandpaper, and then polish with flannelette. Take the above-mentioned polished profile as a sample, and then process it according to the following steps:

[0041] 1) Weigh each component according to the above boronizing agent formula, place it in a planetary ball mill for 1 hour, pass through a 150-mesh sieve, and dry it at 130°C for later use;

[0042] 2) Pretreatment of the sample surface, including:

[0043] A. Soak the sample in a degreasing solution at 80°C for 10 minutes. The formula of the degreasing solution is: each liter of water contains 15g sodium hydroxide, 22g sodium carbonate, 60g phospho...

Embodiment 2

[0059] Boronizing agent composition: 29% Na 2 B 4 o 7 , 10%H 3 BO 3 , 20%B 4 C, 20% KCl, 20% NaCl, 1% KBF.

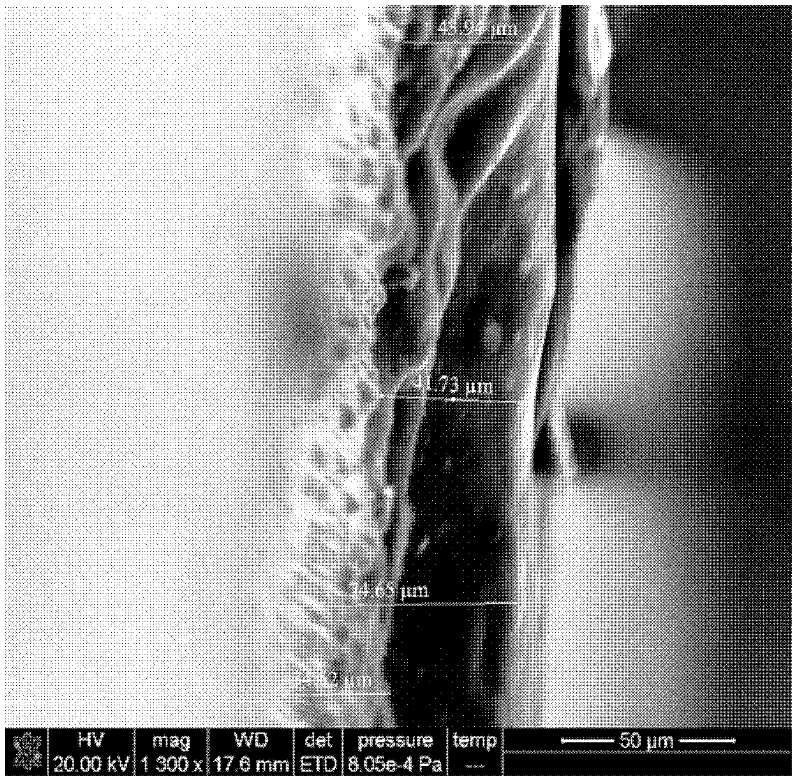

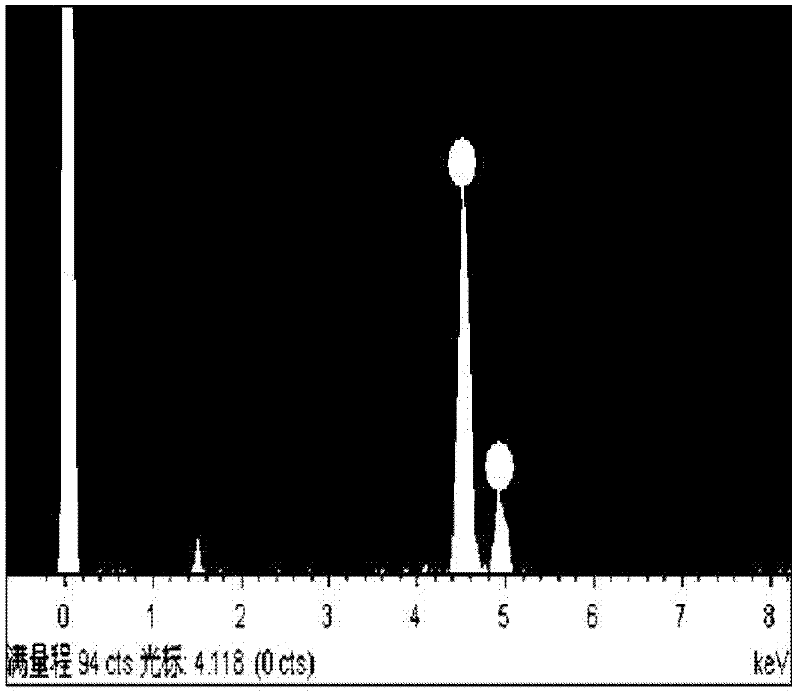

[0060] Firstly, wire-cut the metal titanium plate into 15mm*15mm*3mm (length*width*thickness) profile, use No. 150 sandpaper to roughly grind and polish the profile, and then use No. 600, No. 800 and No. 1200 sandpaper to finely grind and polish. Then polish with flannelette, and take the above-mentioned polished profile as the sample. Take 4 samples and number them respectively as sample 1, sample 2, sample 3 and sample 4, then carry out boronizing, the boronizing process repeats embodiment 1, the difference is that the metal titanium material is immersed in the boronizing agent melt liquid 2cm below the surface, keep warm at 950°C for a period of time, in which the holding time of sample 1 is 30min, the holding time of sample 2 is 60min, the holding time of sample 3 is 90min, and the holding time of sample 4 is 120min ; After the heat preservation is over, the ...

Embodiment 3

[0068] Boronizing agent composition: 34% Na 2 B 4 o 7 , 13%H 3 BO 3 , 17%B 4 C, 16% KCl, 17% NaCl, 3% KBF.

[0069] Boronizing process: The sample used in the test is a pure titanium plate, and the size of the titanium plate is 18mm*18mm*5mm (length*width*thickness). First polish with sandpaper, and then polish with flannelette, and process the sample after the above polishing treatment according to the following steps:

[0070] 1) Weigh each component according to the above boronizing agent formula, place it in a planetary ball mill for 2 hours, dry it at 150°C, and set aside;

[0071] 2) Pretreatment of the sample surface, including:

[0072] A. Soak the sample in a degreasing solution at 80°C for 10 minutes. The formula of the degreasing solution is: 13g sodium hydroxide, 25g sodium carbonate, 60g phosphoric acid and 8g sodium silicate per liter of water;

[0073] B. Take out the sample from the degreasing solution, and then put it into the soaking solution for 5 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com